Patents

Literature

40results about How to "Expand the variety range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing extra-deep drawing cold-rolled steel plate based on ASP process

InactiveCN101941021AReduce manufacturing costMeet needsRoll mill control devicesWork treatment devicesProduction lineAcid washing

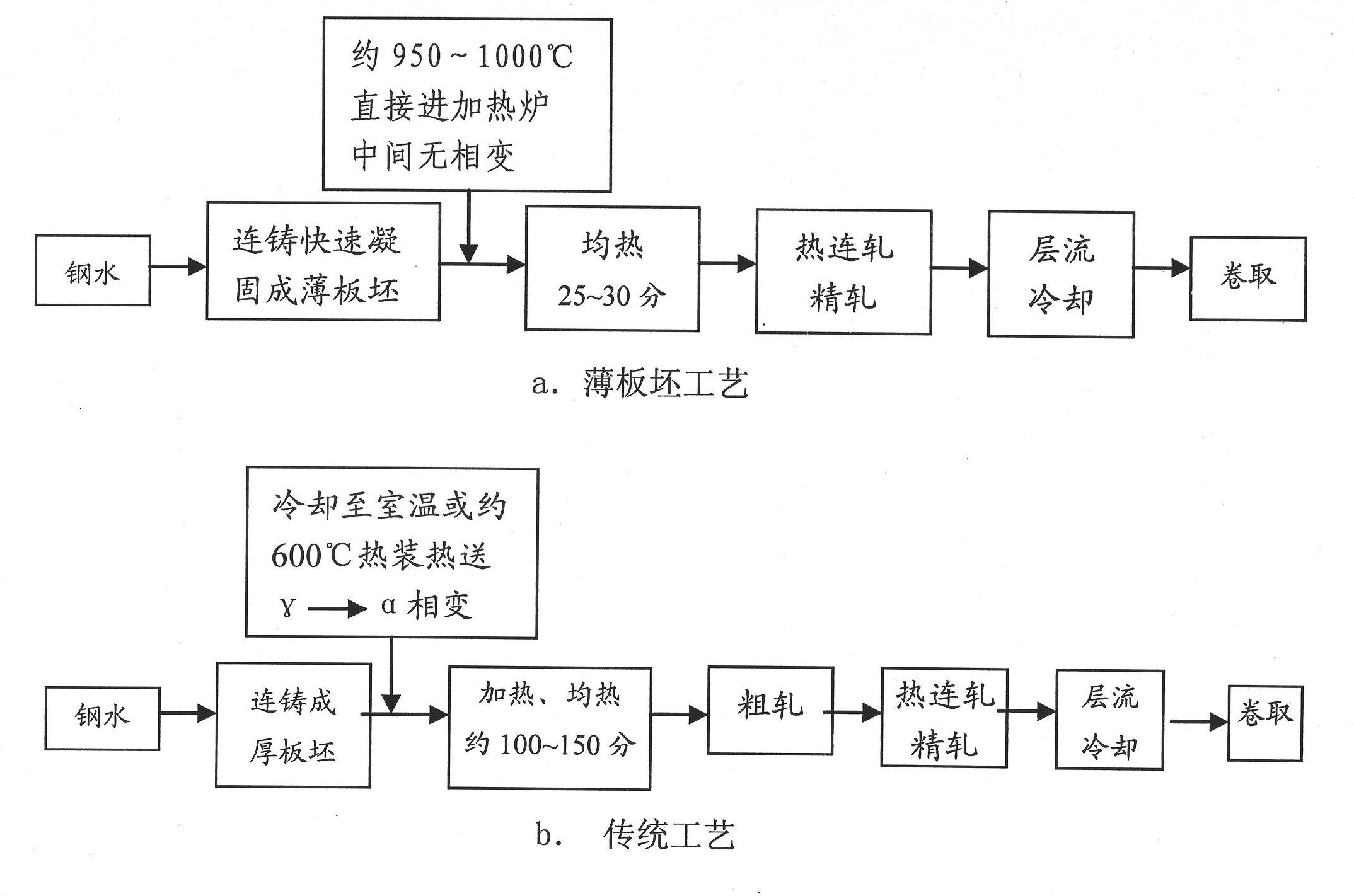

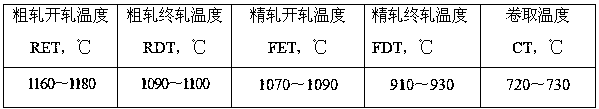

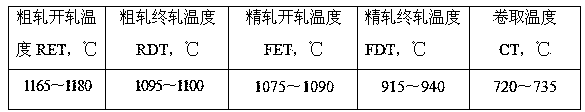

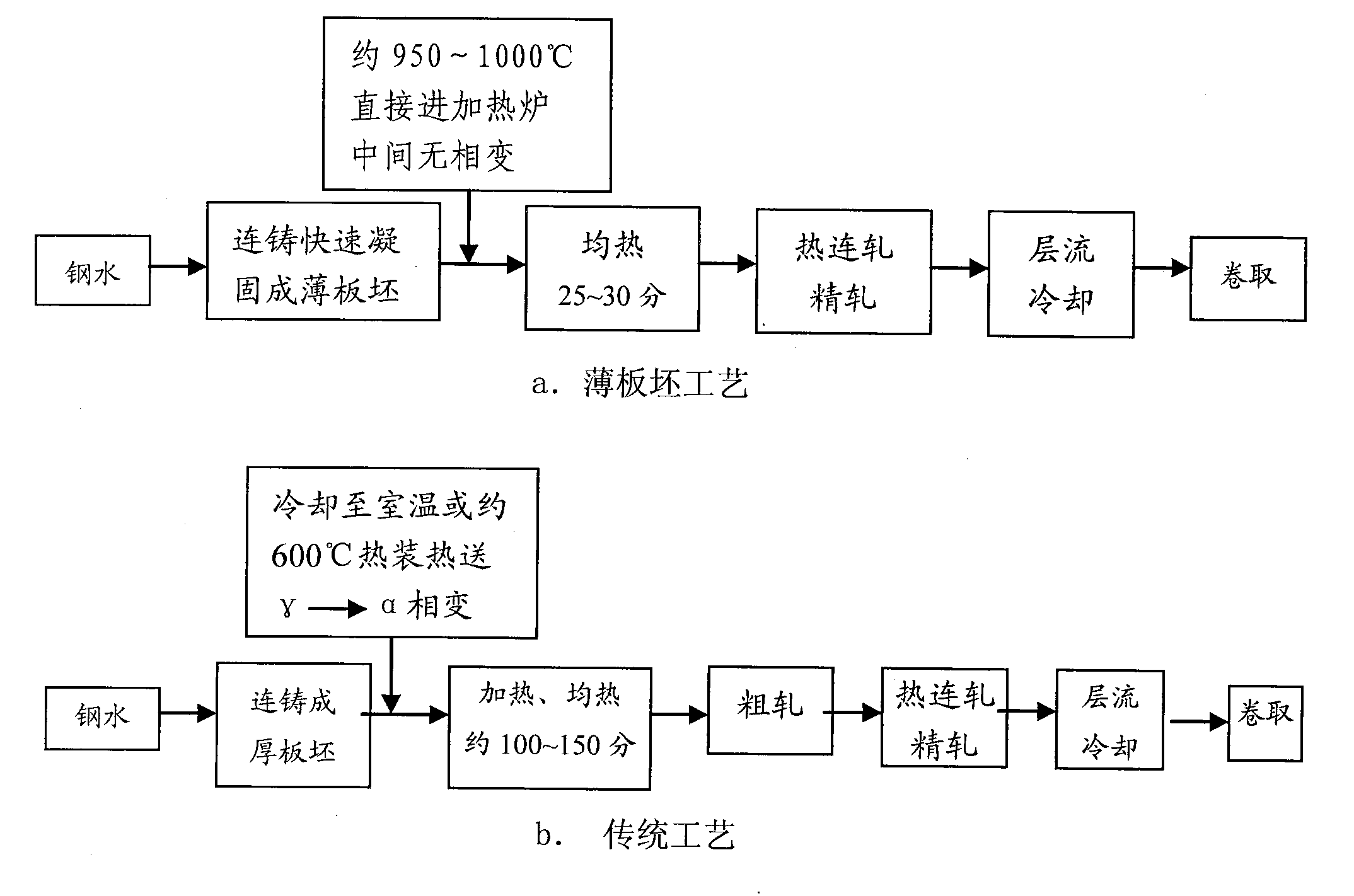

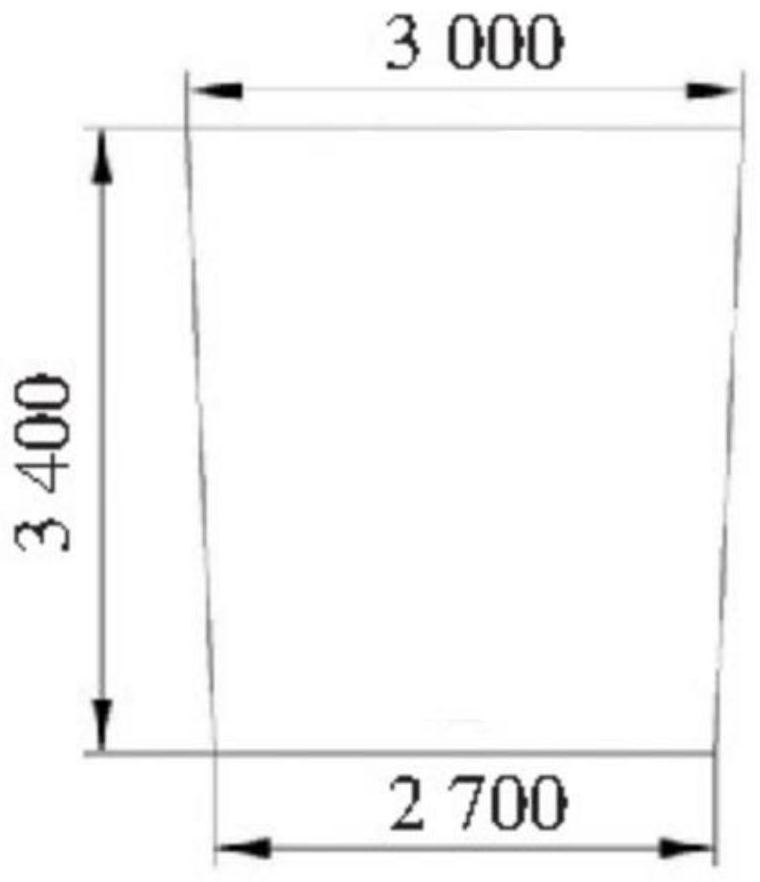

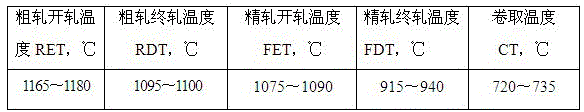

The invention discloses a method for producing an extra-deep drawing cold-rolled steel plate based on a sheet billet continuous casting and rolling process in ASP, and belongs to the technical field of rolled steel. After molten steel meeting the component requirement is obtained by adopting molten iron pretreatment, a converter, LF and RH, a hot-rolled substrate is produced by the sheet billet continuous casting and rolling process in the ASP, and the hot-rolled substrate is subjected to acid washing, cold rolling, cover annealing and leveling processes to obtain the extra-deep drawing cold-rolled steel plate. Compared with the prior art, the performance of the produced extra-deep drawing cold-rolled steel plate meets the European standard EN10130-2006, meanwhile, the production cost is reduced, energy is saved and consumption is reduced. The method broadens the variety range of products produced by a sheet billet continuous casting and rolling production line in the ASP, can meet the increasing requirements of the industries of automobiles, home appliances, buildings, transports, light industry and the like for plates, and improves the product competitiveness of enterprises.

Owner:SHANDONG IRON & STEEL CO LTD +1

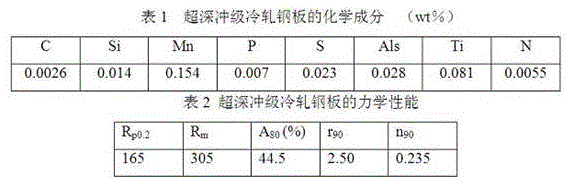

Super deep-drawing cold-rolled enamel steel produced by ASP diplex process and manufacturing method thereof

InactiveCN103469075AExcellent formability and scale resistanceBroaden the range of product varietiesAluminiumMetal

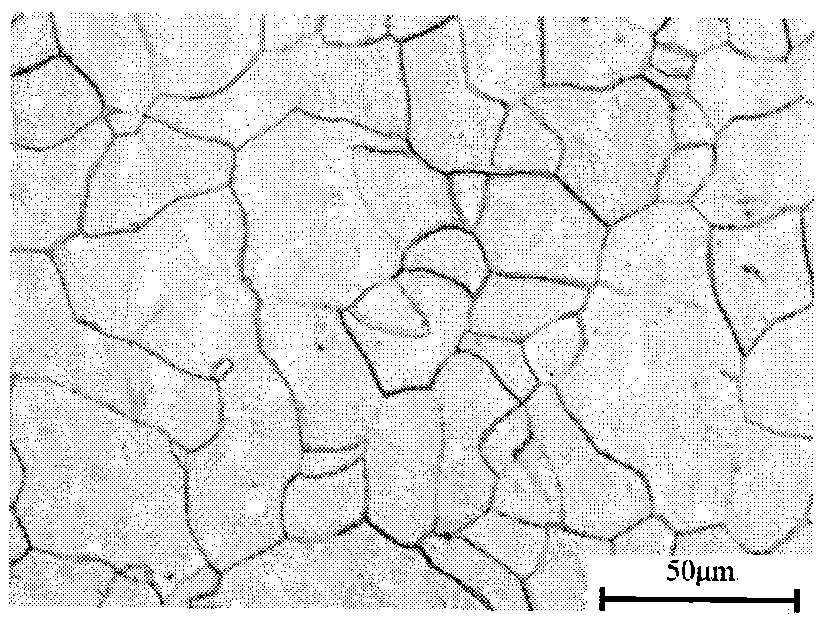

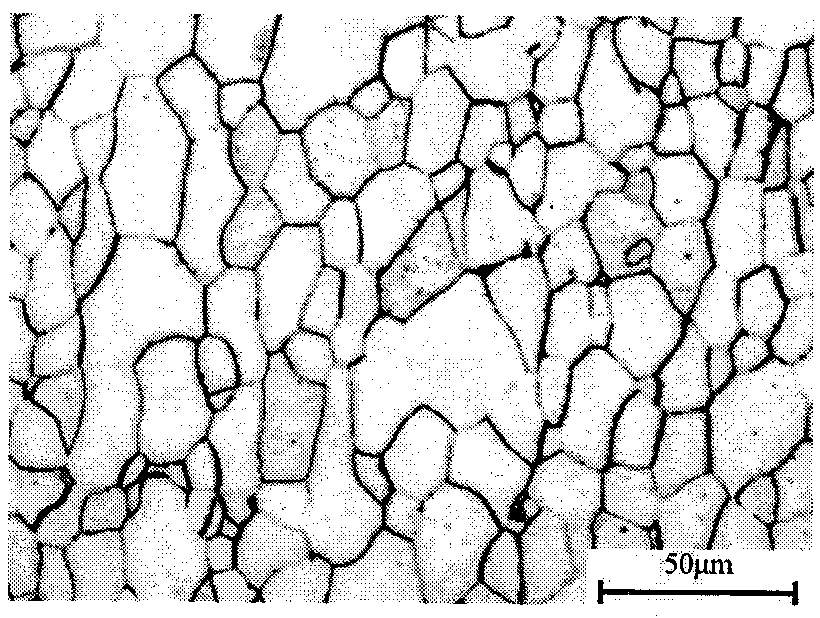

The invention belongs to the technical field of metal material manufacturing, and in particular relates to super deep-drawing cold-rolled enamel steel produced by an ASP diplex process and a manufacturing method thereof. The enamel steel comprises the following components in percentage by weight: less than or equal to 0.005% of carbon, less than or equal to 0.030% of silicon, 0.10 to 0.35% of manganese, less than or equal to 0.015% of phosphorus, 0.015 to 0.035% of sulfur, 0.015 to 0.050% of acid dissolved aluminum, 0.070 to 0.10% of titanium, 0.0040 to 0.0070% of nitrogen, and the balance of iron and unavoidable impurities. The manufacturing method comprises the following steps of: (1) smelting by a converter, (2) refining by an LF (ladle furnace), (3) vacuum-refining by an RH furnace, (4) continuously casting and rolling, (5) washing by acid, cold-rolling, annealing and flattening. By adoption of the LF and RH diplex process, the mass production of the super deep-drawing cold-rolled enamel steel is successfully realized on an ASP production line.

Owner:JIGANG GRP

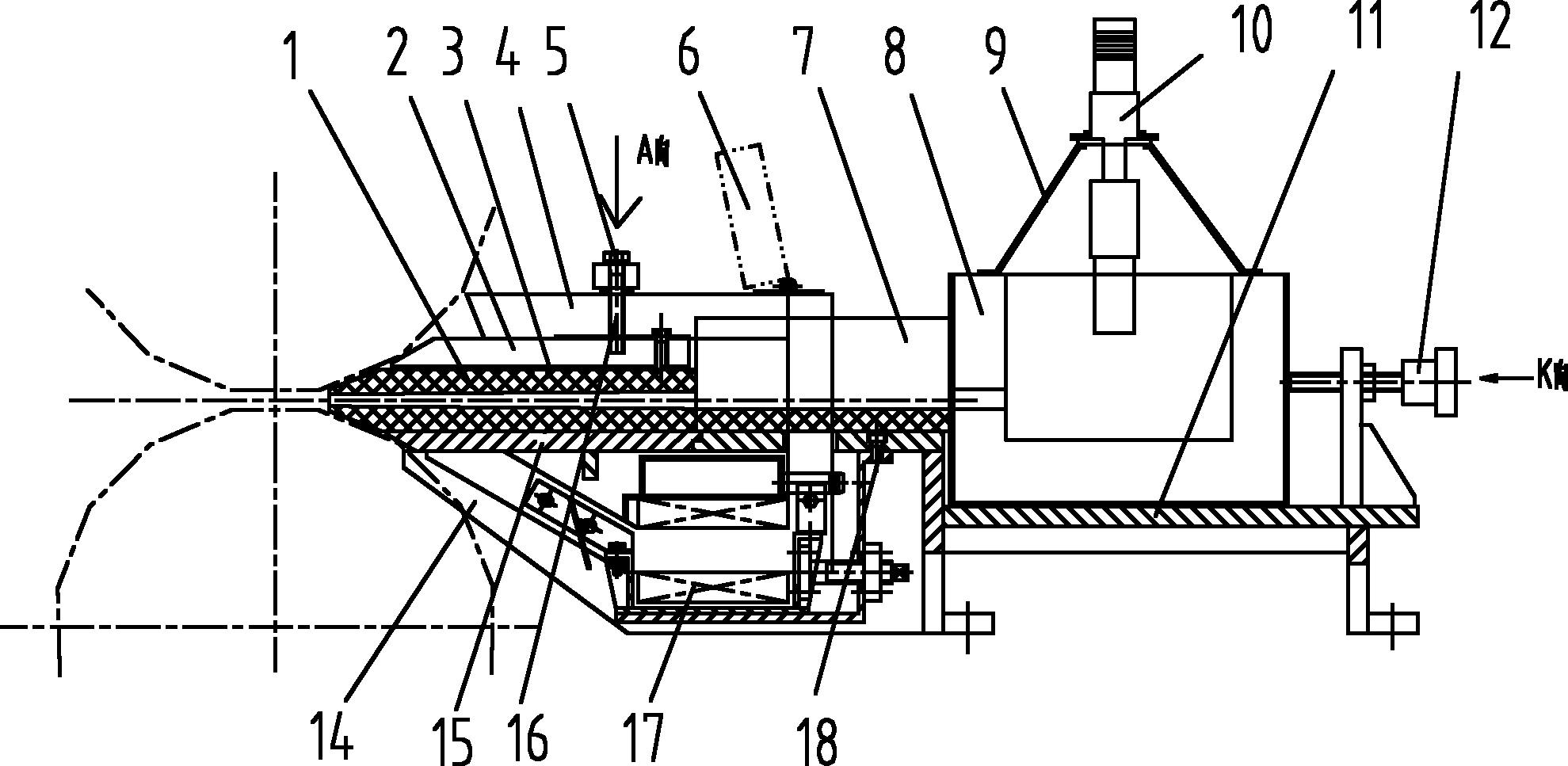

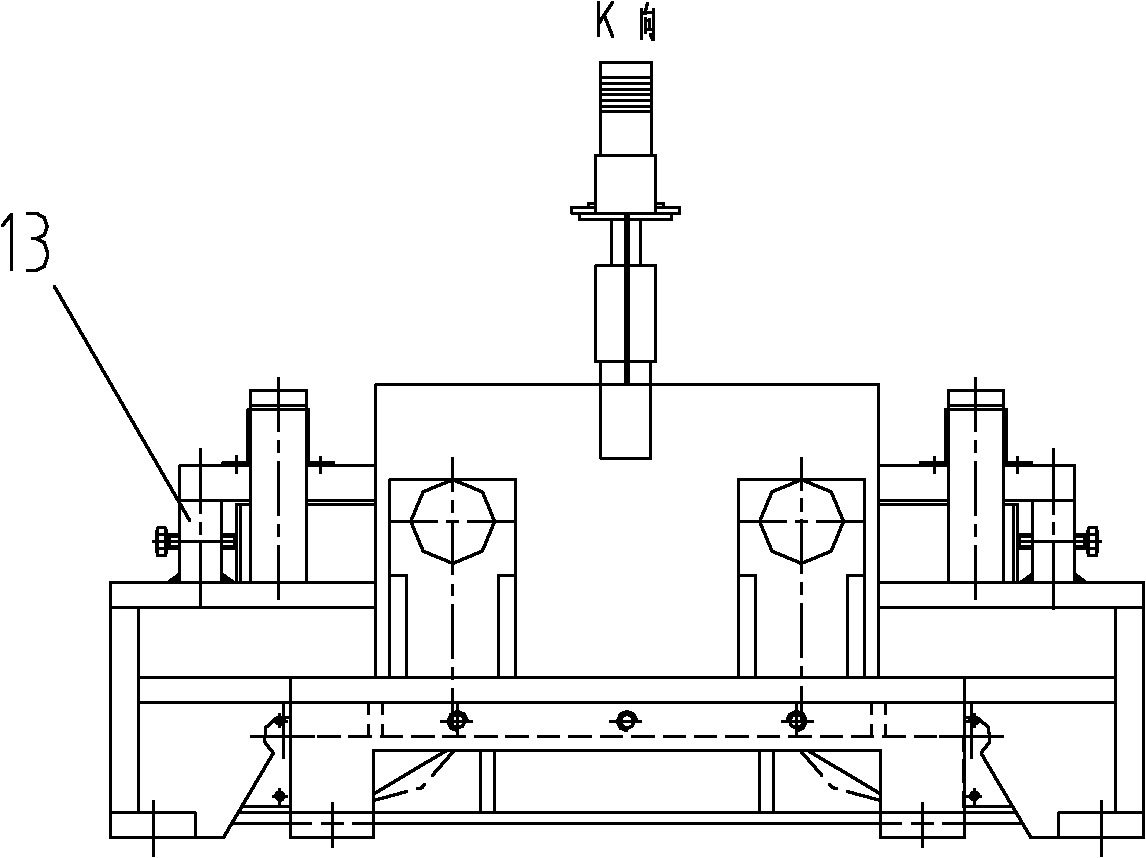

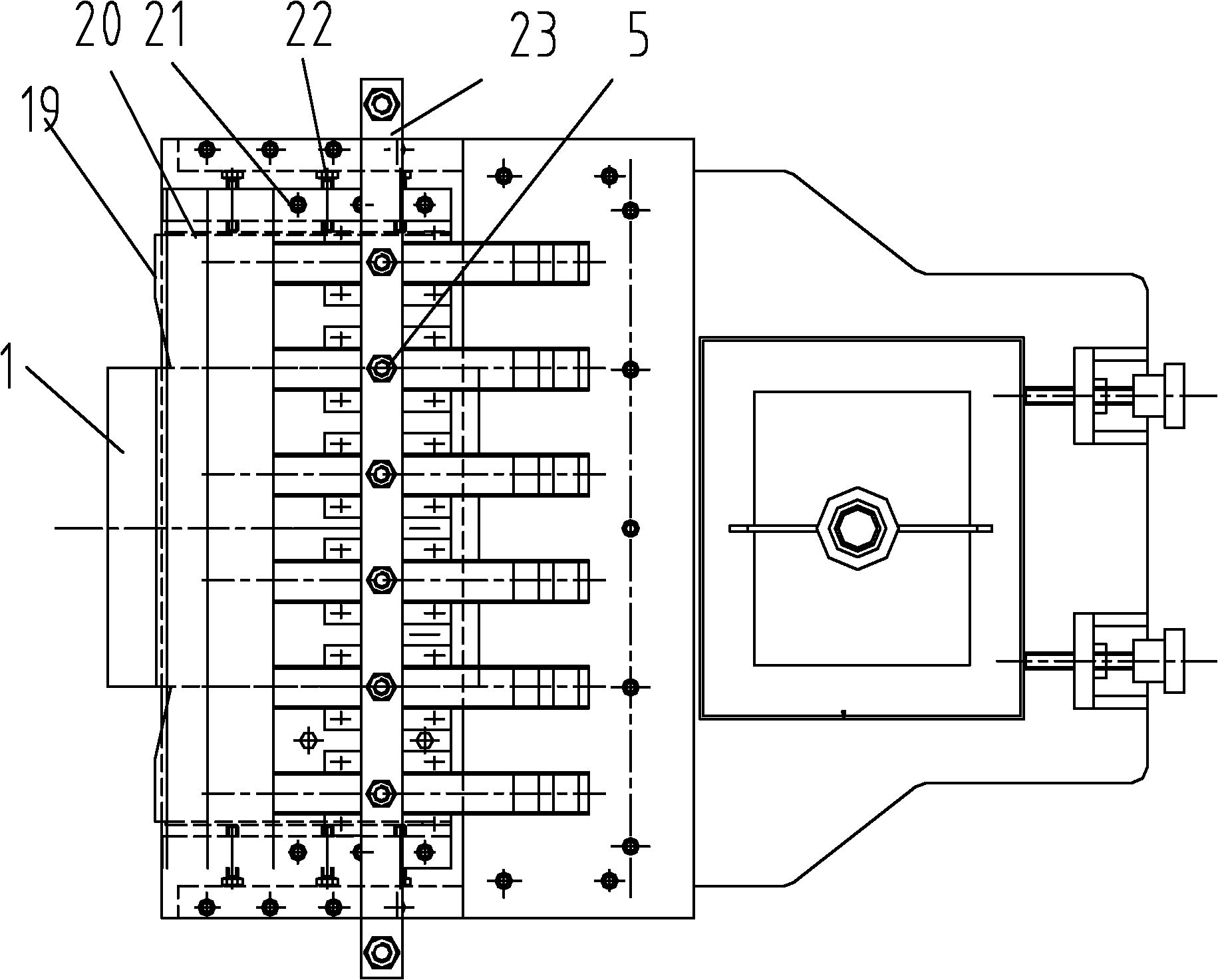

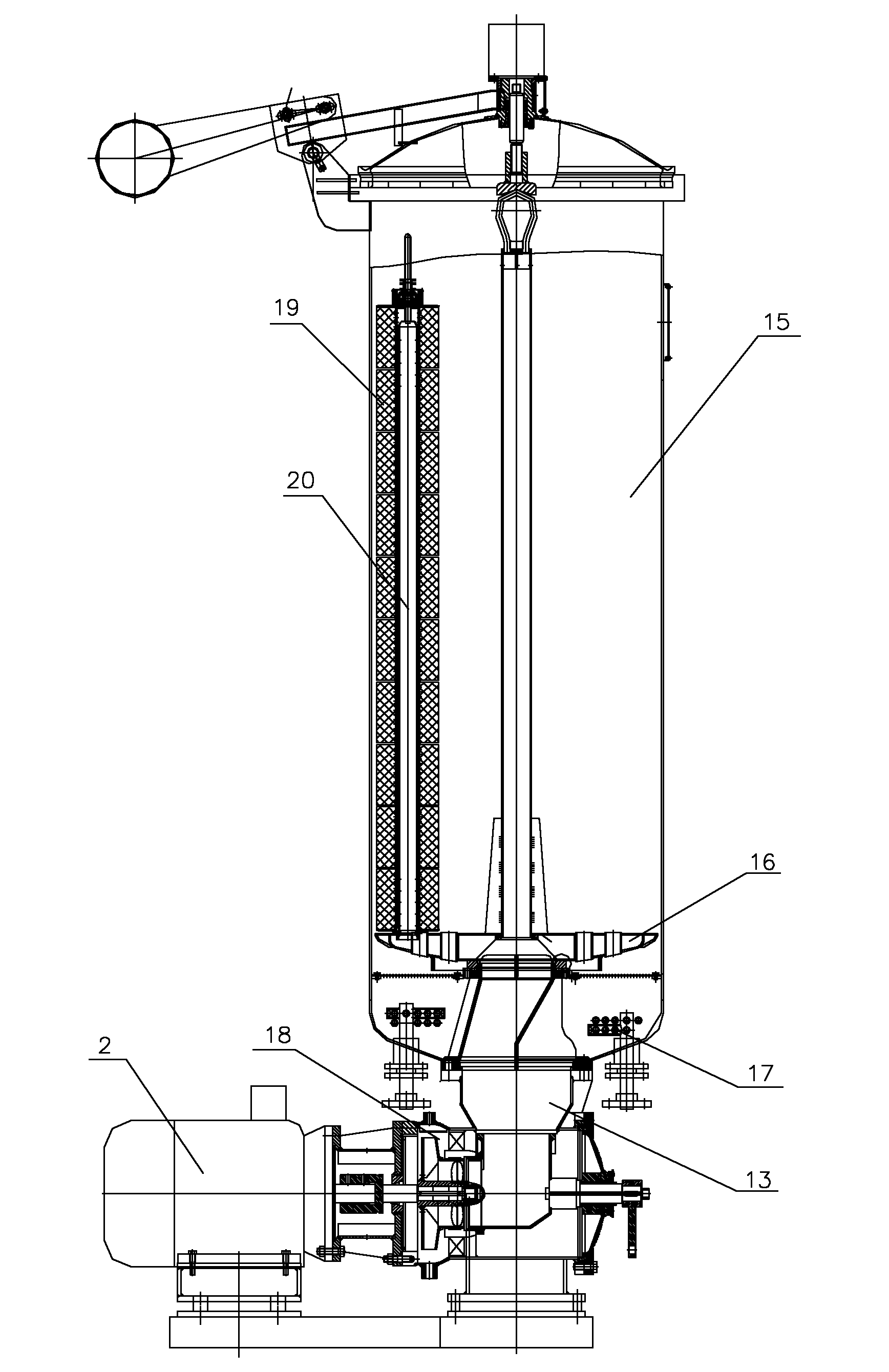

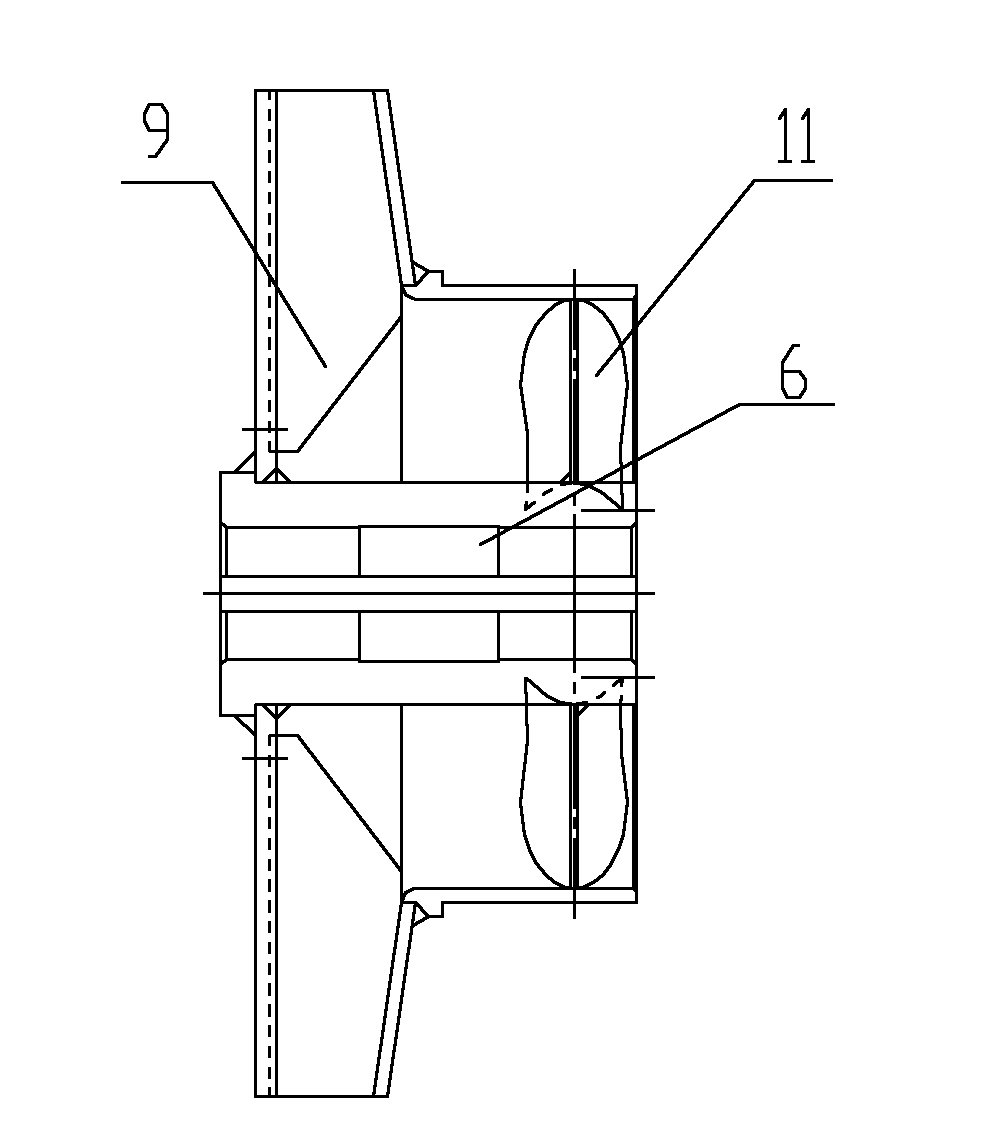

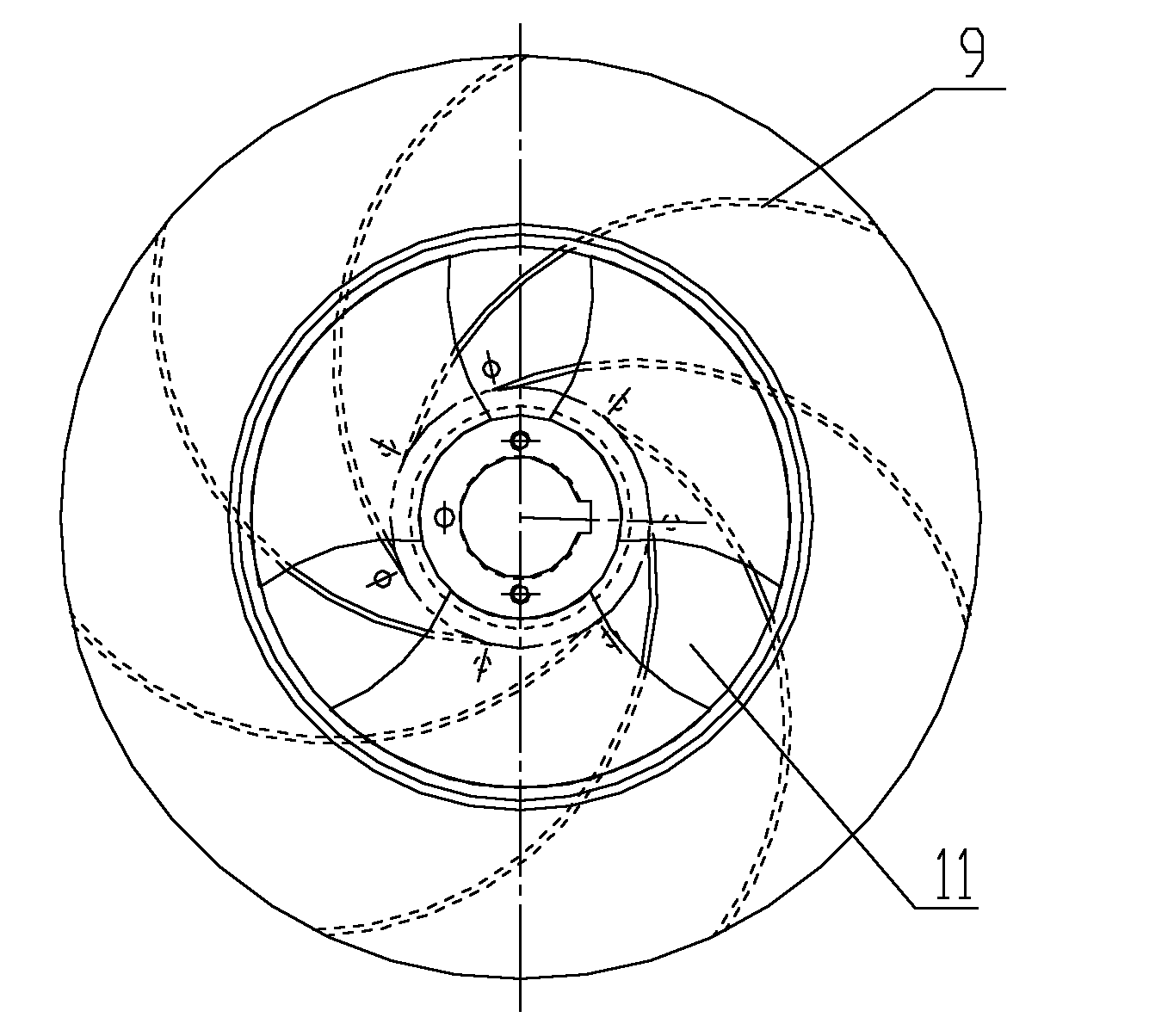

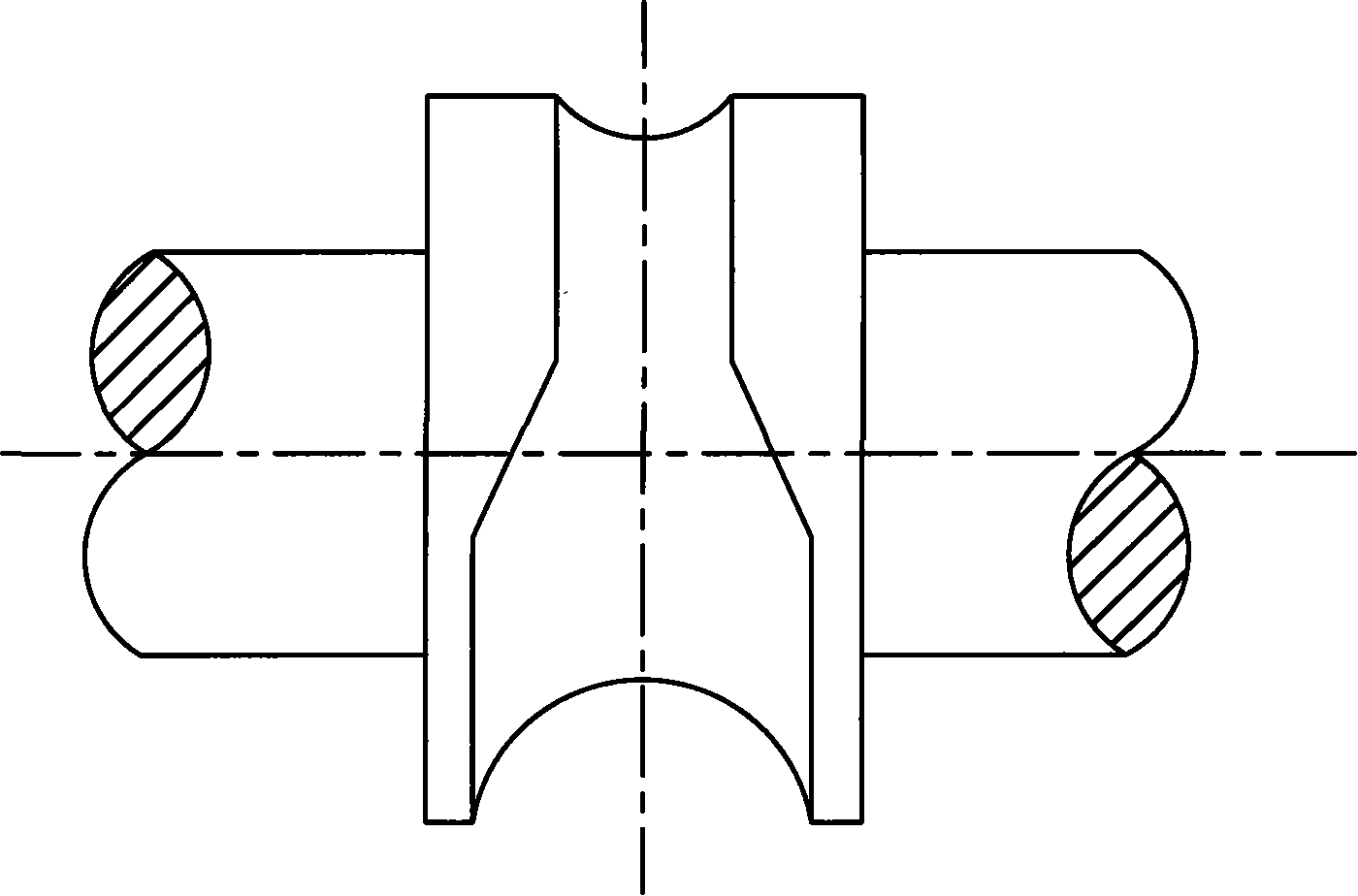

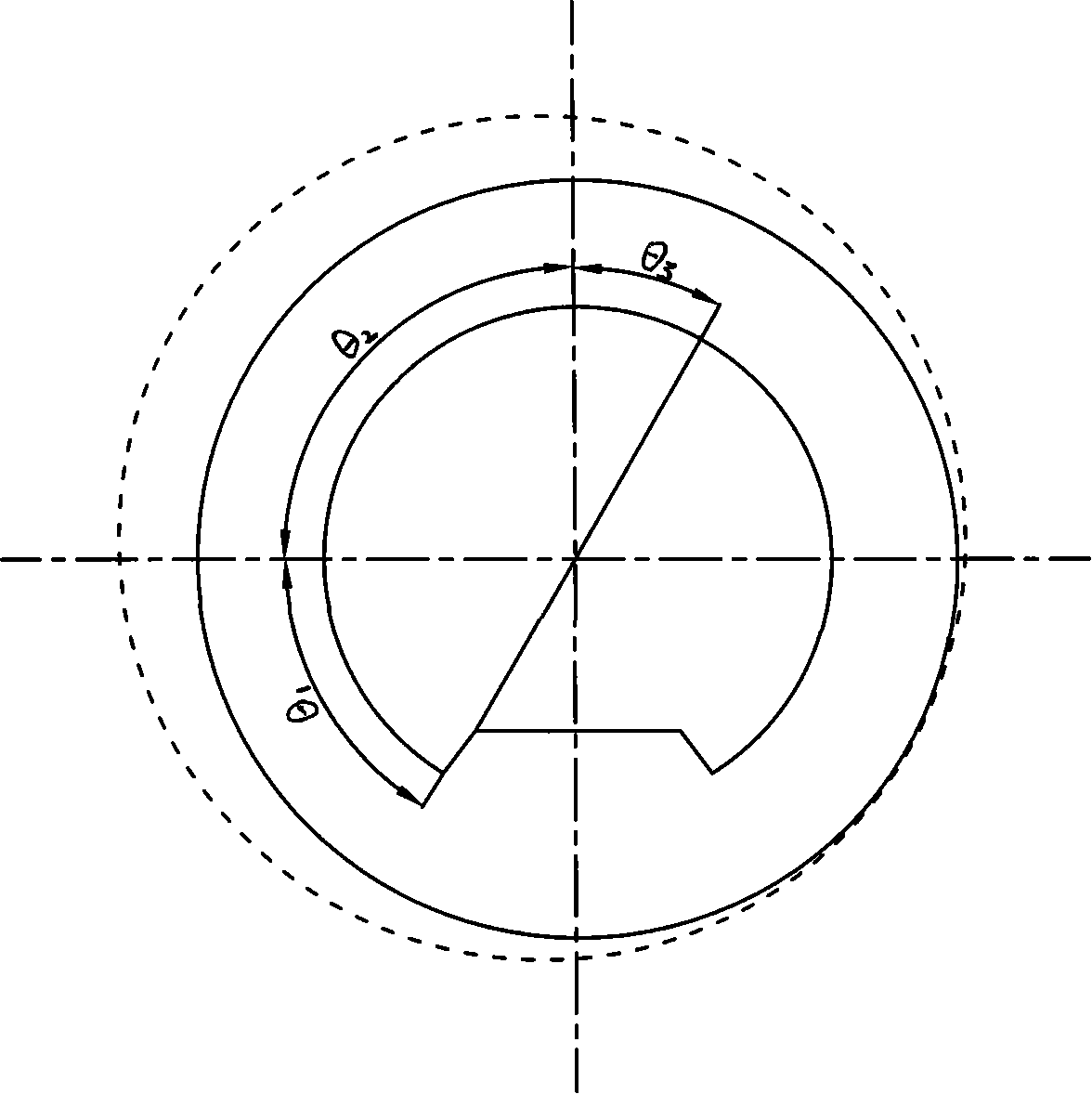

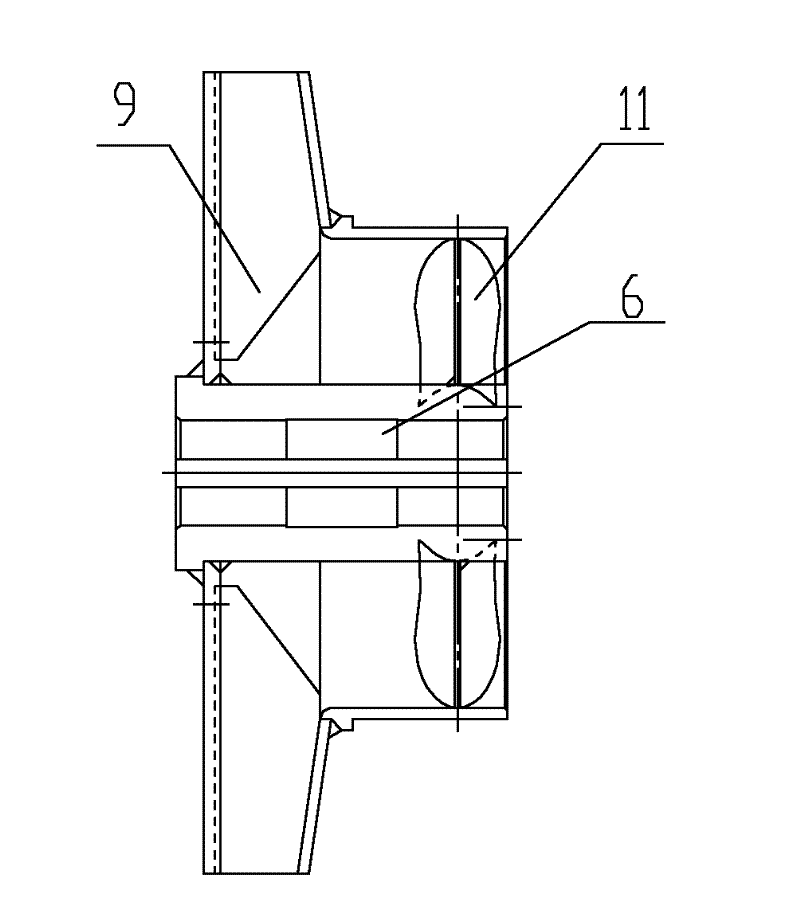

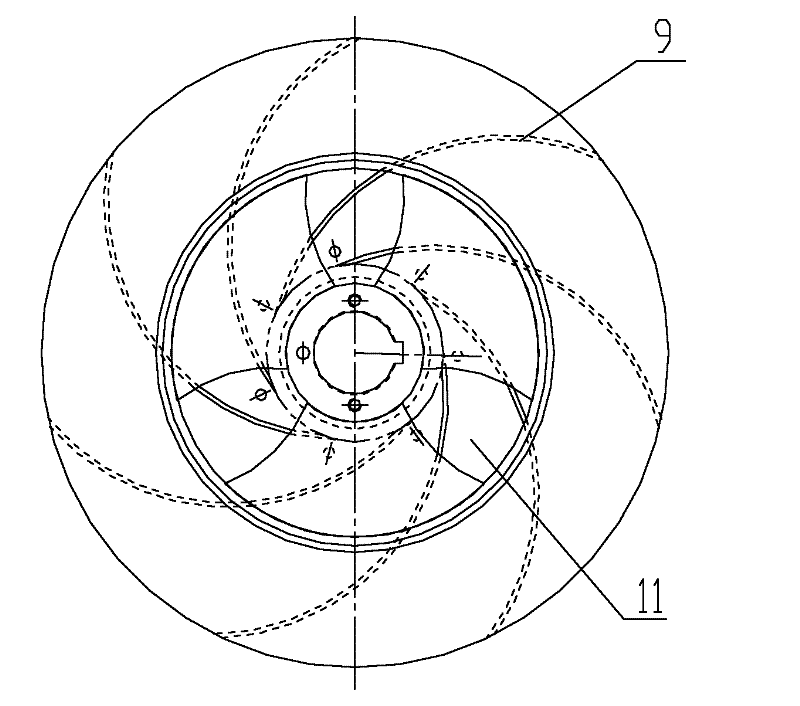

Electromagnetic/ultrasound compound outfield continuous casting and rolling device

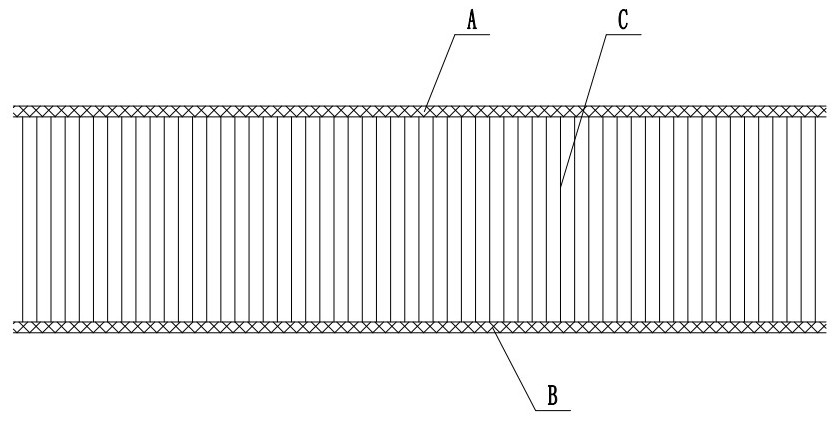

InactiveCN101844212AEnhanced convective heat transferUniform temperature fieldEngineeringMicroscopic scale

The invention discloses an electromagnetic / ultrasound compound outfield continuous casting and rolling device. A frame body (14) is fixedly provided with a magnetic field generator (17) distributed along the axial direction of a roller; a vibration-proof bar (23) is connected with and arranged on the frame body (14); at least one upper iron core (4) distributed along the axial line of the roller is connected to the vibration-proof bar (23) through a first bolt (5); the upper iron core (4) is connected with a movable iron core (6) through a hinge; an upper press plate (2) and an upper liner plate (3) are arranged between the upper iron core (4) and a casting nozzle (1); a supporting rod (9) is connected to a front box (8) and is provided with an ultrasound generator (10); and an ultrasound toolhead of the ultrasound generator (10) extends into the front box (8). The invention relates to the electromagnetic / ultrasound compound outfield continuous casting and rolling device which can refine a casting and rolling texture, increase the mechanical property, improve the anisotropy, reduce or eliminate segregation, macro and micro flaws and achieve long service life of the casting nozzle in the continuous casting and rolling process of an aluminum alloy casting and rolling plate billet.

Owner:CENT SOUTH UNIV

Water repellent finishing agent and method for manufacturing moisture absorbing and sweat releasing jean fabric by using same

The invention relates to a water repellent finishing agent, which comprises the following components in percentage by mass: 50 to 80 percent of fluorine-containing emulsion, 10 to 30 percent of resin finishing agent, 5 to 20 percent of softening agent and 0.3 to 2 percent of thickening agent; and pH value buffer solution is added to adjust the pH value of the water repellent finishing agent to between 4 and 7. The invention also relates to a method for manufacturing moisture absorbing and sweat releasing jean fabric by using the water repellent finishing agent, which comprises the following steps: performing water repellent coating finishment on the inner side of the jean fabric by using the water repellent finishing agent; and not treating the outer side of the jean fabric to keep the hydrophilicity of cotton, wherein the water repellent coating finishment process comprises the steps of coating the inner side of the jean fabric, pre-drying, baking, and cooling and cloth falling; the pre-drying temperature is between 80 and 135DEG C, and the time is 1 to 150 minutes; and the baking temperature is between 110 and 170DEG C and the time is 2 to 10 minutes. By adopting the water repellent finishing agent and the method for manufacturing the moisture absorbing and sweat releasing jean fabric, common jean fibers can be manufactured into the moisture absorbing and sweat releasing jean fabric with good washing fastness and strong processability.

Owner:GUANGDONG JUNAN JEANS RES INST

Production process of colorful soft denim

InactiveCN105803761AShrinkage stableStable weightInspecting textilesLiquid/gas/vapor removalGramShrinkage rate

The invention discloses a production process of colorful soft denim. The production process comprises the specific steps as follows: pre-treating; feeding cloth-immersing in water and penetrating-straightening weft; and overfeeding-drying-dyeing-dehydrating-washing with ferment-washing and whitening-feeding a softening agent-sizing. By virtue of the process, the air permeability can be effectively improved, the light shading property is reduced, the perspective property of a fabric is avoided and an ultra-soft denim fabric with soft and light texture is prepared; a condition that the denim is faded can be effectively reduced, the stability of the shrinkage rate and the gram weight of the denim are guaranteed and the sizing property is good; and an optimal fabric condition is created for clothes manufacturing. Meanwhile, the problems of traditional denim that the color is single, a fabric surface style is dull and visual impact is lacked are solved, and the trend of times is adapted.

Owner:TAICANG QIDE GARMENT

Process of manufacturing cloisonne silverware

ActiveCN102173271AReduce heat conduction speedSlow down heat dissipationSpecial ornamental structuresHeat conductingCopper

The invention belongs to the technical field of cloisonne manufacture, in particular to a process for manufacturing cloisonne silverware. A body is made of silver, and filamentary silver is used for filigree; and the process comprises the following process steps of: rolling the body; soldering filigree; welding; filling enamel; firing the enamel; and polishing, wherein after an enamel filling procedure, the inner wall of a silver body is filled with a cool medium material, the cloisonne silverware filled with the cool medium material is put into a furnace for enamel firing, and the cloisonne silverware is immediately taken out of the furnace once the enamel is melted. In the process for manufacturing the cloisonne silverware, the adopted cool medium material effectively reduces the heat conducting or heat dissipating speed of the silver body, the problem of corrosion of a copper body is solved, and the silver is used as an inner body, so that the cloisonne has health-care effect and higher visual aesthetic feeling.

Owner:SHANXI YINMANLOU JINGTAILAN SILVER PRODS

Production process of snow-wash jean cloth

InactiveCN105755658AShrinkage stableStable weightFabric breaking/softeningSolvent-treatmentGramReduction ratio

The invention discloses a production process of snow-wash jean cloth. The production process particularly comprises the following steps of cloth feeding, water infiltration, weft finishing, overfeeding, baking, float stone dry grinding, plate aligning and cleaning, neutralization, softening agent applying and shaping. According to the production process, the situation of fading of jean cloth can be effectively alleviated, furthermore, the stabilities of reduction ratio and gram weight of the jean cloth are guaranteed, the shaping property is good, and an optimal cloth surface condition is created for production of clothes.

Owner:TAICANG QIDE GARMENT

Xylon polymerized composite material and its preparation method

The present invention discloses a xylon polymerized composite material and its preparation method. The xylon polymerized composite material provided by said invention contains 65-85 wt% of modified xylon raw material, 10-30 wt% of thermoplastic material and 5-10 wt% of additive. The modified xylon raw material is obtained by spraying reactive initiator into the broken xylon raw material, sealing and stacking the above-mentioned material. Said xylon polymerized composite material can be made into various products instead of various plastics and wood material.

Owner:陈根长

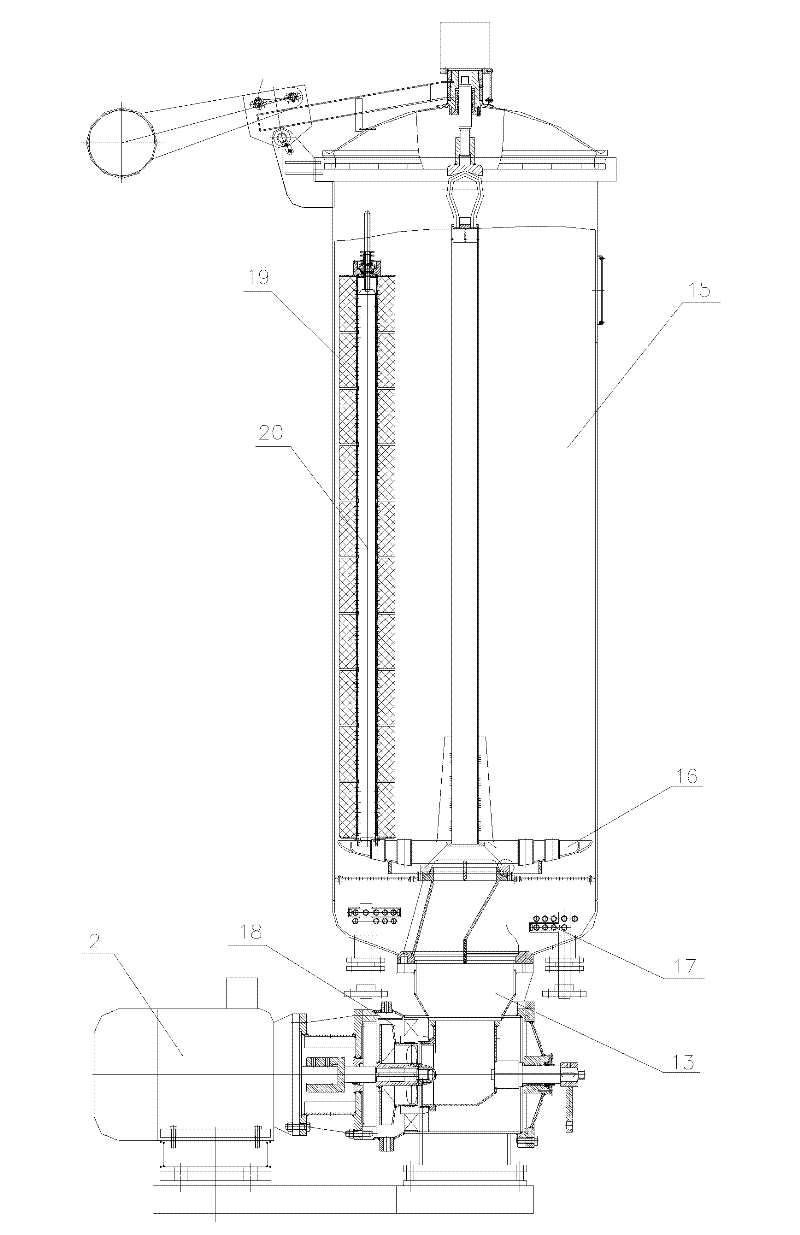

High-temperature pulse flow yarn dyeing machine with ultra low bath ratio and control method thereof

InactiveCN102140743AIncrease exchange frequencyQuick responseTextile treatment machine arrangementsTextile/flexible product manufactureYarnThree level

The invention discloses a high-temperature pulse flow yarn dyeing machine with an ultra low bath ratio and a control method thereof. The yarn dyeing machine comprises a dye vat, a creel, a heat exchange coiler, an adaptive water level monitoring device, a variable frequency motor, a three-level vane pump with an ultra low bath ratio and a dyeing computer. The method comprises the following steps: a time pulse generator in the dyeing computer gives out pulse flow data to a variable frequency motor controller to control the revolving rate of the variable frequency motor according to the set technological process; the variable frequency motor drives the three-level vane pump with an ultra low bath ratio to output dyeing flow in pulse flow type fluctuation; the output dyeing flow carries out adaptive adjustment according to an ideal reference model in the dyeing computer; the adaptive water level monitoring device gives out water-level reference identification information; and according to the information, a water level regulator and the variable frequency motor controller respectively regulate the water level and the variable frequency motor to reach the water level and the pulse flow required by the set technological process. The pulse flow dyeing technology in the invention conforms to the requirement of the minimum consumption of four factors, namely, water, energy, accessory ingredient and time for economical dyeing of ecological environment protection.

Owner:高勋绿色智能装备(广州)有限公司

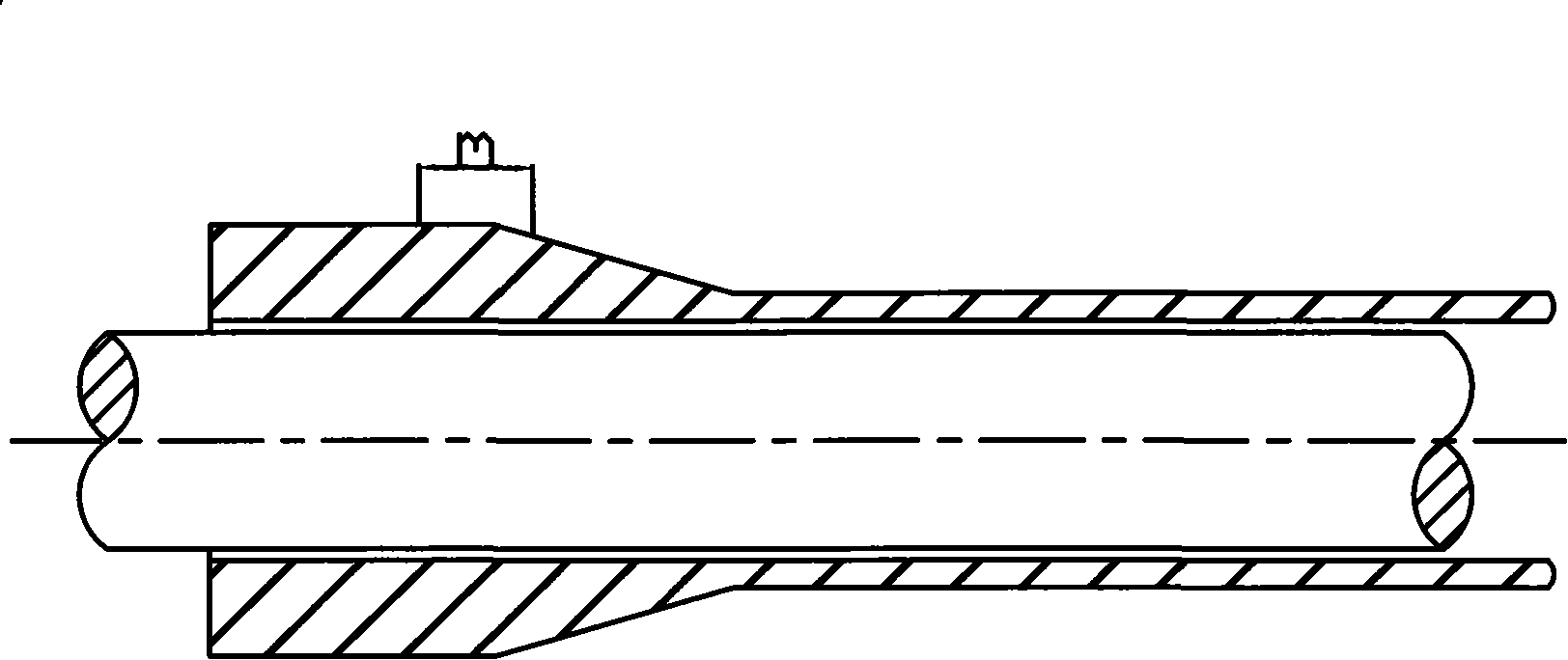

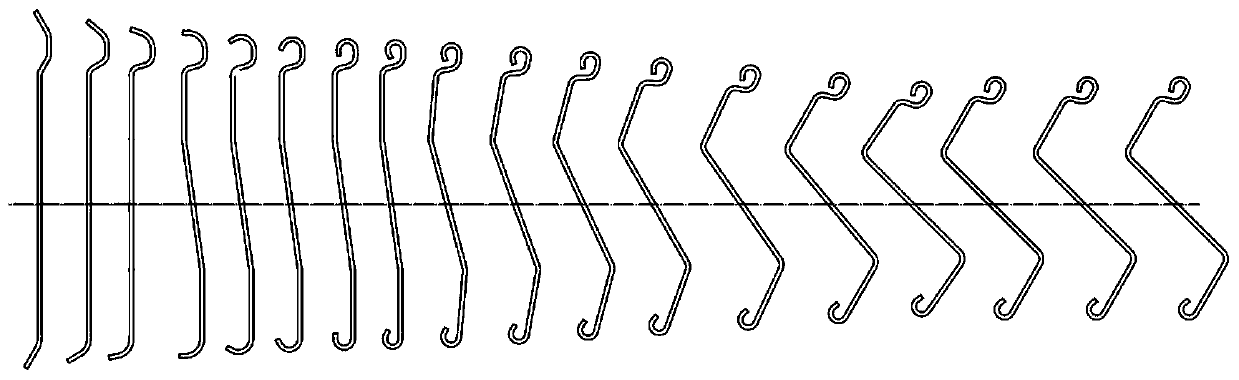

Method for producing seamless steel pipe with reversible reciprocating periodic time hot rolling technique

InactiveCN101249508AImprove rolling efficiencyExpand the variety rangeMetal rolling arrangementsEconomic benefitsEngineering

The invention discloses a method for manufacturing seamless steel pipes by adopting a reversible repeated periodic hot rolling technology. A plurality of frames are arranged along the movement direction of a rolling stock, rollers are arranged on each frame in vertical direction, each cross section of a pass of the rolling mill has identical shape and consists of three arc segments. The method comprises the following processing steps of: penetrating the rolling stock through a mandrel and feeding to a roller, biting the rolling stock by the roller to achieve rolling in forward travel, reversing the roller when the forward-travel rolling finished, accurately reversing the rolling stock by a certain angle, feeding into the pass of the roller to achieve reversible rolling deformation, and repeating the steps by multiple times until achieving the prescribed size. The method can achieve reversible repeated rolling and greatly improve the rolling efficiency, and is particularly suitable for producing extra-thick wall pipes and low-plasticity alloy steel pipes without intermediate reheating, thus saving the energy resource. The generation of pilger bell ends is obviated in the production, thus improving the rolling yield and achieving better economic benefit.

Owner:ZHONGXING ENERGY EQUIP

Manufacturing process for soft denim

InactiveCN105780498AShrinkage stableStable weightSucessive textile treatmentsLiquid/gas/vapor removalShrinkage rateEngineering

The invention discloses a manufacturing process for soft denim. The manufacturing process comprises the following specific steps: feeding fabric, impregnating the fabric with water to be thoroughly permeated, perofrming weft-straightening and overfeeding, braking, washing with enzymes, cleaning and whitening, applying a softening agent, and forming. According to the process, the air permeability can be effectively improved, the light-proofness is reduced, the fabric perspectivity is avoided, and super-soft denim fabric with soft and thin texture can be obtained; moreover, fading situations of the denim can be reduced effectively; the shrinkage rate of the denim and the stability of gram weight are ensured; the forming property is high; the best fabric cover condition is created for clothes manufacturing.

Owner:TAICANG QIDE GARMENT

Manufacturing technology of colorful insulation jean

InactiveCN105671839AShrinkage stableStable weightFibre treatmentHeating/cooling textile fabricsManufacturing technologyPermeation

The invention discloses a manufacturing technology of a colorful insulation jean.The technology comprises the specific steps of pretreatment, fabric feeding, water soaking permeation, weft finishing, overfeeding, baking, dyeing, sizing, washing, softening agent applying, sizing and molding.The manufacturing technology can effectively reduce the phenomenon that the jean fades, the reduction ratio of the jean and the gram weight stability are ensured, the sizing performance is good, the best fabric face condition is created for manufacturing clothes, meanwhile, the problems that a tradition jean is single in color, the fabric face is tedious in style, and the jean lacks visual impact are solved, and the colorful insulation jean has both the traditional insulation function and modern fashionable elements.

Owner:TAICANG QIDE GARMENT

Manufacturing process of warming and soft denim

InactiveCN105780359AShrinkage stableStable weightLaminationHeating/cooling textile fabricsGramEnzyme

The invention discloses a manufacturing process of warming and soft denim.The manufacturing process includes the following specific steps of denim feeding-water infiltration-weft-straightening and overfeeding-baking-enzyme wash-washing and whitening-softening agent applying-shaping and forming.By means of the process, breathability can be effectively improved, the shading property can be lowered, the see-through property of a fabric is avoided, the super soft denim fabric which is soft, light and thin in texture is obtained, fading of the denim can be effectively reduced, cloth shrinkage and stability of gram weight of the denim are guaranteed, settability is good, a best cloth cover condition is created for clothing making, and the denim fabric can have the traditional warm keeping function and the modern fashionable element.

Owner:TAICANG QIDE GARMENT

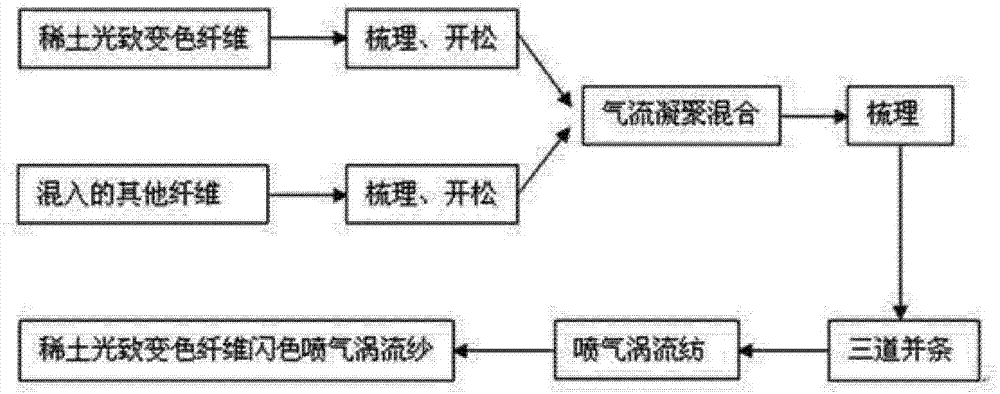

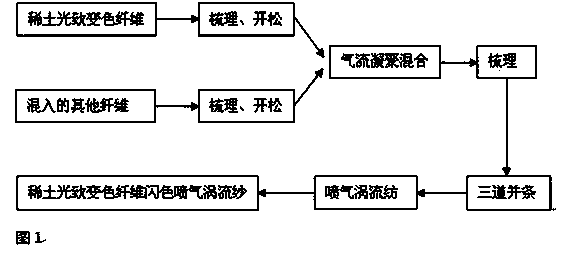

A kind of rare earth photochromic flashing color air-jet vortex yarn processing method

ActiveCN104233550BAvoid stainsReduce manufacturing costContinuous wound-up machinesOpen-end spinning machinesYarnCarding

The invention discloses a processing method of rare-earth photochromic flashing air-jet vortex yarn, which comprises the following steps: respectively carding and opening rare-earth photochromic fibers and other fibers; using airflow to quantify rare-earth photochromic fibers and other fibers Condensation and mixing; then carding, and three drawing frames; use air-jet vortex spinning to process the mixed fibers to obtain rare earth photochromic fiber flashing color air-jet vortex spinning after drafting, twisting, winding, and winding. In the present invention, the rare earth photochromic fiber is blended with other natural-colored fibers or the colored fiber with obvious color contrast with the rare-earth photochromic fiber or the mixture of the natural-colored fiber and the colored fiber. The thread presents a flashing effect; on the other hand, the prepared yarn no longer needs a dyeing process, which avoids the problem of difficult dyeing of rare earth photochromic fibers, and reduces production costs at the same time.

Owner:SHAOXING UNIVERSITY

Production technology of low-phosphorous stainless steel

Owner:AVIC SHANGDA METAL REGENERATION TECH

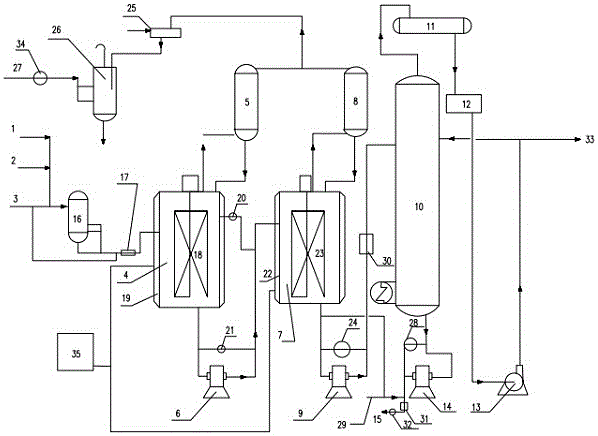

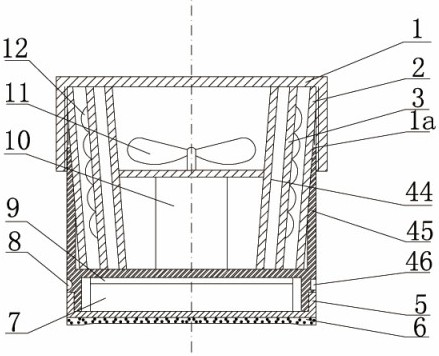

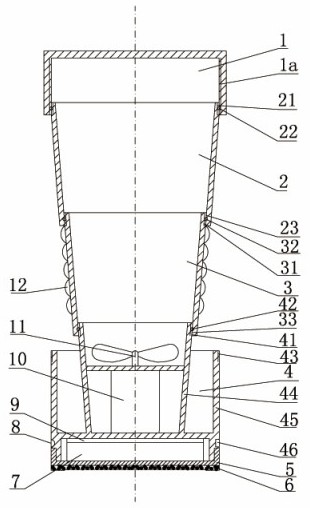

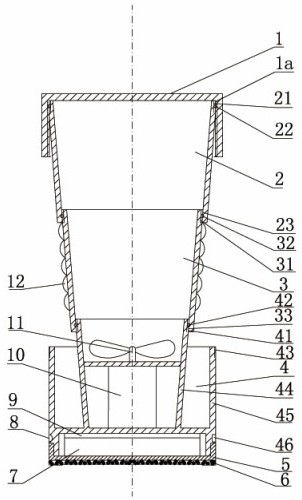

Production device of PVA multi-product polymerization system

The invention discloses a production device of a PVA multi-product polymerization system, belonging to the field of chemical engineering. The system device comprises the following main equipment: a polymerizing pot 1, a polymerizing pot 1 resin pump, a polymerizing pot 2, a polymerizing pot 2 resin pump, a polymerizing column 1, a polymerizing column 1 pot pump, a PVAC storage tank, a polymerizing preheater, a mixer, a polymerizing pot 1 agitator, a polymerizing pot 1 jacket, a polymerizing pot 2 jacket, a polymerizing pot 2 agitator, a nitrogen gas buffer tank, a water seal pressurizing tank, a column 1 level control valve, dissolution methanol, a pot 2 outlet liquid mixer, a column 1 pot outlet resin mixer and a polymerizing column 2. The equipment is interconnected through pipelines. The technical scheme of the invention can realize integrated control of a multi-product production process as well as safe and quick control of a product transformation process. The product transformation process needs not reduction in amount and can maintain the maximum amount as design. Meanwhile, an SIS system can satisfy treatment under special working conditions and ensure safety of a polymerization process.

Owner:SINOPEC CHANGCHENG ENERGY CHEM NINGXIA CO LTD

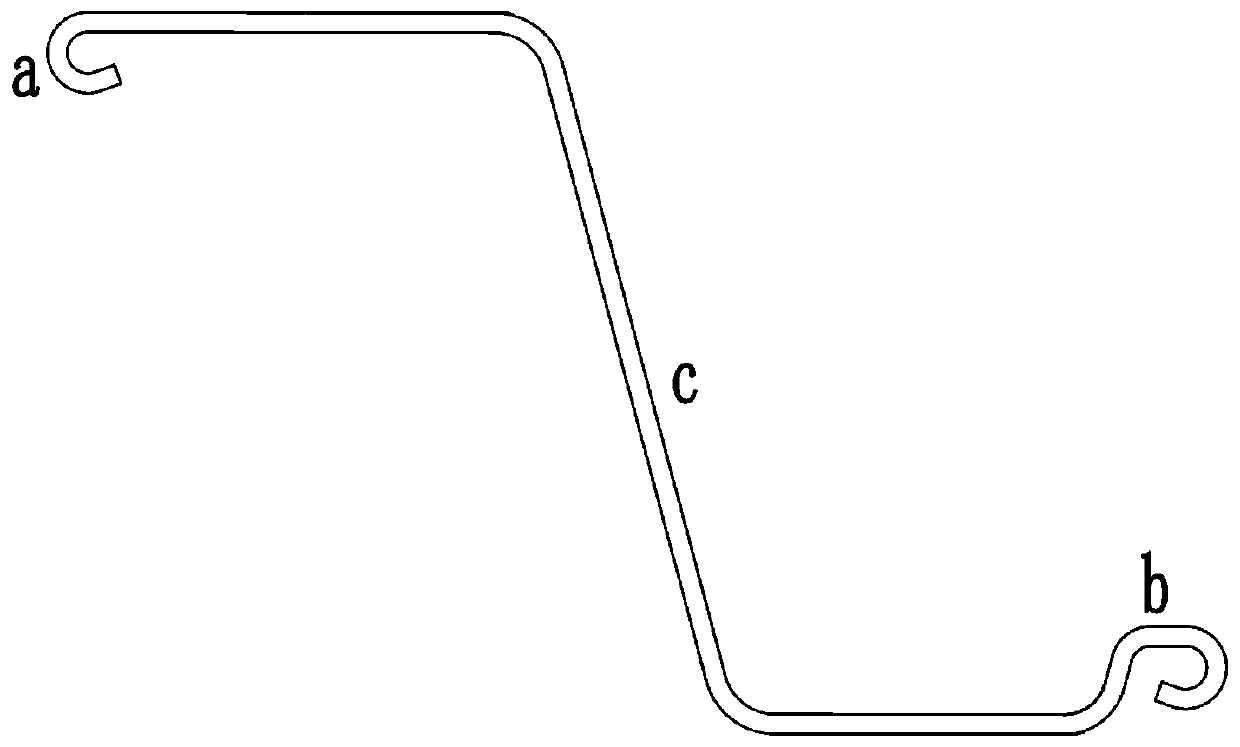

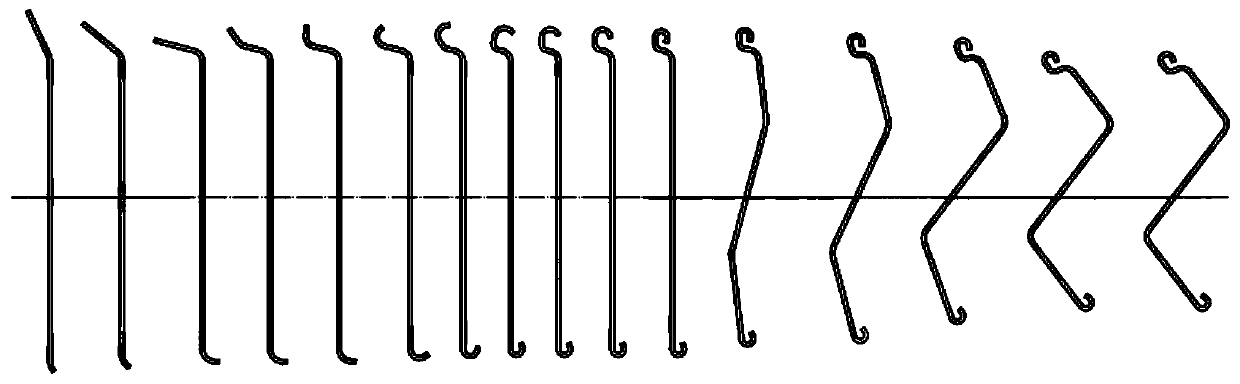

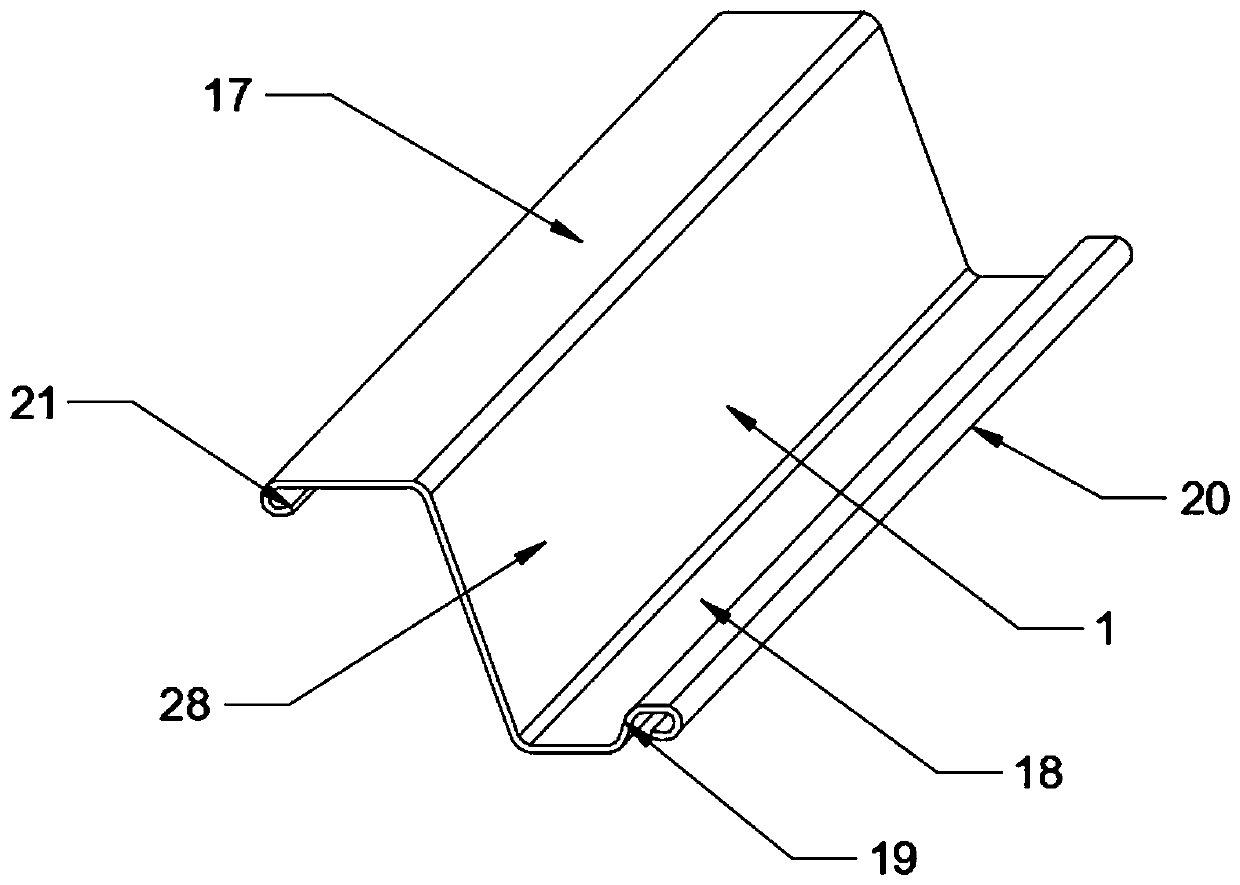

Roller type continuous cold roll forming method for Z-shaped steel sheet pile

InactiveCN111014434AExpand the variety rangePotential releaseShaping toolsStructural engineeringRoll forming

The invention discloses a roller type continuous cold roll forming method for a Z-shaped steel sheet pile. The method comprises the steps of feeding, uncoiling, flattening, roller type continuous coldbending deformation, finishing, cutting and the like; and a lock hook is formed through a descending hooking method. The method is reasonable is design and clear in logic; one set of product mold canbe used for producing various steel sheet pile products; side vertical rollers are not needed during lock hook deformation, so that torque is saved, and energy consumption is reduced; unit potentialis released, the specifications of machinable products are expanded, the market adaptability is high; the product specification exchange speed is high, and the labor cost is reduced; and the market application of the cold-bending steel sheet pile is expanded, and the variety range of the steel sheet pile is further expanded.

Owner:南京图信新材料科技有限公司

High-temperature pulse flow yarn dyeing machine with ultra low bath ratio and control method thereof

InactiveCN102140743BIncrease exchange frequencyQuick responseTextile treatment machine arrangementsTextile/flexible product manufactureYarnThree level

The invention discloses a high-temperature pulse flow yarn dyeing machine with an ultra low bath ratio and a control method thereof. The yarn dyeing machine comprises a dye vat, a creel, a heat exchange coiler, an adaptive water level monitoring device, a variable frequency motor, a three-level vane pump with an ultra low bath ratio and a dyeing computer. The method comprises the following steps:a time pulse generator in the dyeing computer gives out pulse flow data to a variable frequency motor controller to control the revolving rate of the variable frequency motor according to the set technological process; the variable frequency motor drives the three-level vane pump with an ultra low bath ratio to output dyeing flow in pulse flow type fluctuation; the output dyeing flow carries out adaptive adjustment according to an ideal reference model in the dyeing computer; the adaptive water level monitoring device gives out water-level reference identification information; and according to the information, a water level regulator and the variable frequency motor controller respectively regulate the water level and the variable frequency motor to reach the water level and the pulse flow required by the set technological process. The pulse flow dyeing technology in the invention conforms to the requirement of the minimum consumption of four factors, namely, water, energy, accessory ingredient and time for economical dyeing of ecological environment protection.

Owner:高勋绿色智能装备(广州)有限公司

Method for processing rare earth photochromic color flash air-jet vortex spun yarns

ActiveCN104233550AAvoid stainsReduce manufacturing costContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention discloses a method for processing rare earth photochromic color flash air-jet vortex spun yarns. The method comprises the following steps of carding and opening rare earth photochromic fibers and other fibers respectively; performing quantitative cohesion and blend on the rare earth photochromic fibers and other fibers by using airflow; carding cotton and performing a three-pass drawing procedure; drawing, twisting, spooling and winding blended fibers by using air-jet vortex spinning to obtain rare earth photochromic fiber color flash air-jet vortex spun yarns. The rare earth photochromic fibers and other natural color fibers, colored fibers in obvious contrast to the rare earth photochromic color, or a mixture of natural color fibers and colored fibers is blended, so that the characteristics of the rare earth photochromic fibers are fully utilized to enable the yarns to present a color flash effect, the prepared yarns do not require a dyeing procedure to avoid the problem that the rare earth photochromic fibers are difficultly dyed, and the production cost is reduced.

Owner:SHAOXING UNIVERSITY

The shaping method of knitted denim

ActiveCN103088587BShrinkage stableStable weightHeating/cooling textile fabricsTextile manufacturingDenim

The invention relates to the technical field of textile manufacturing, and especially relates to a knitted denim fixing method. The method comprises the following steps: conveying a knitted denim by a denim charging mechanism, and allowing the knitted denim to go through a denim guide roll having a narrow groove and used for preventing the knitted denim from crimping in the conveying process; allowing the knitted denim conveyed through the denim guide roll to reach a penetration water tank and the knitted denim to fully penetrate in water and absorb water until the water content of the knitted denim is 60-80%; rectifying the deflection of the weft filaments of the penetrated knitted denim through a weft adjusting device; and adjusting the knitted denim speed, fixing the knitted denim through a fixing oven, cooling, and finally doffing. The addition of the penetration water tank to a fixing machine in the invention makes the knitted denim fully penetrate in water and absorb water to guarantee the shrinkage rate and the gram stabilization of the knitted denim, so a best denim cover condition is created from the knitted denim fixing, and the kind range of the knitted denim is substantially increased.

Owner:JIANGSU ZHENGHENG DYEING FINISHING

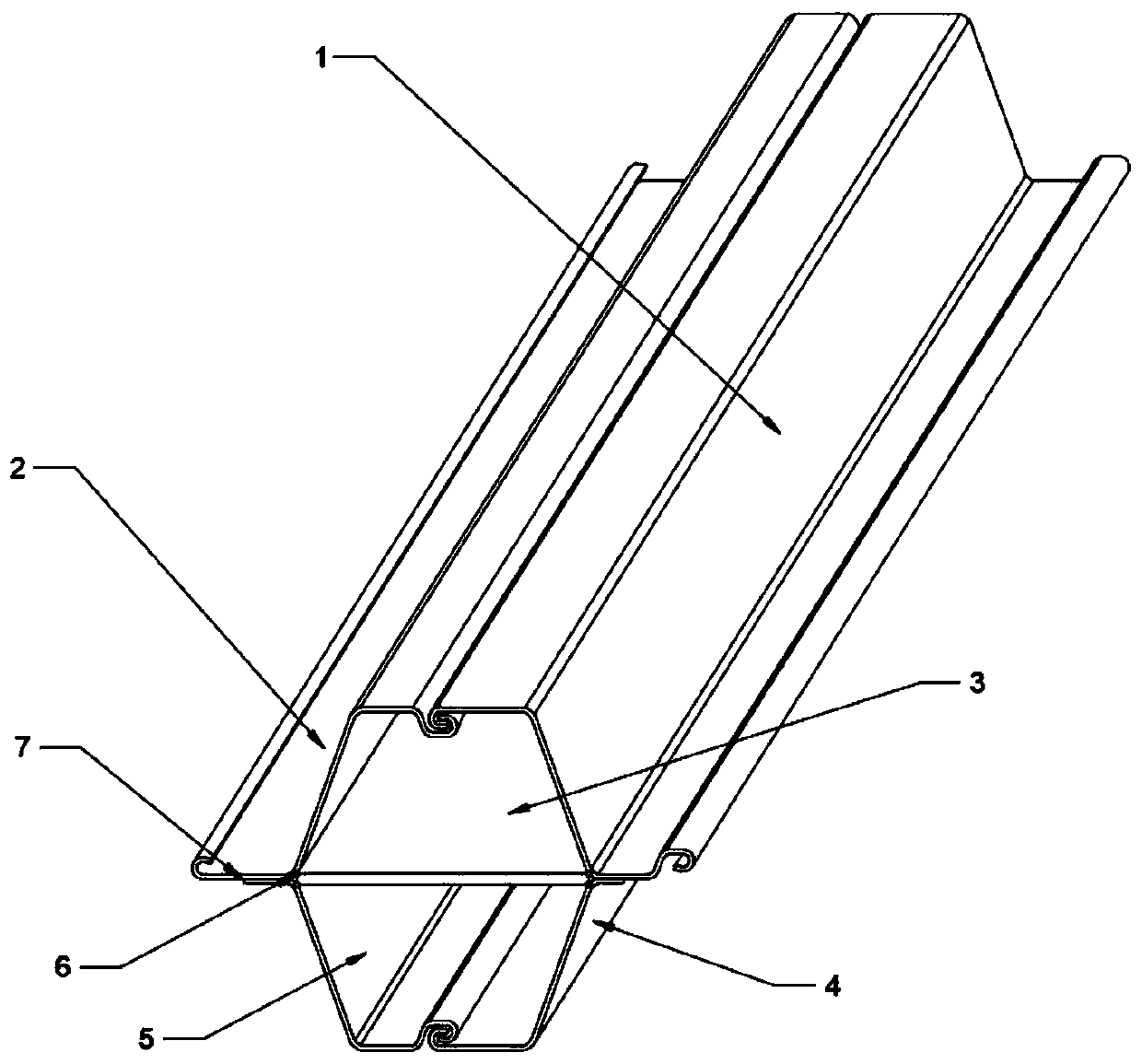

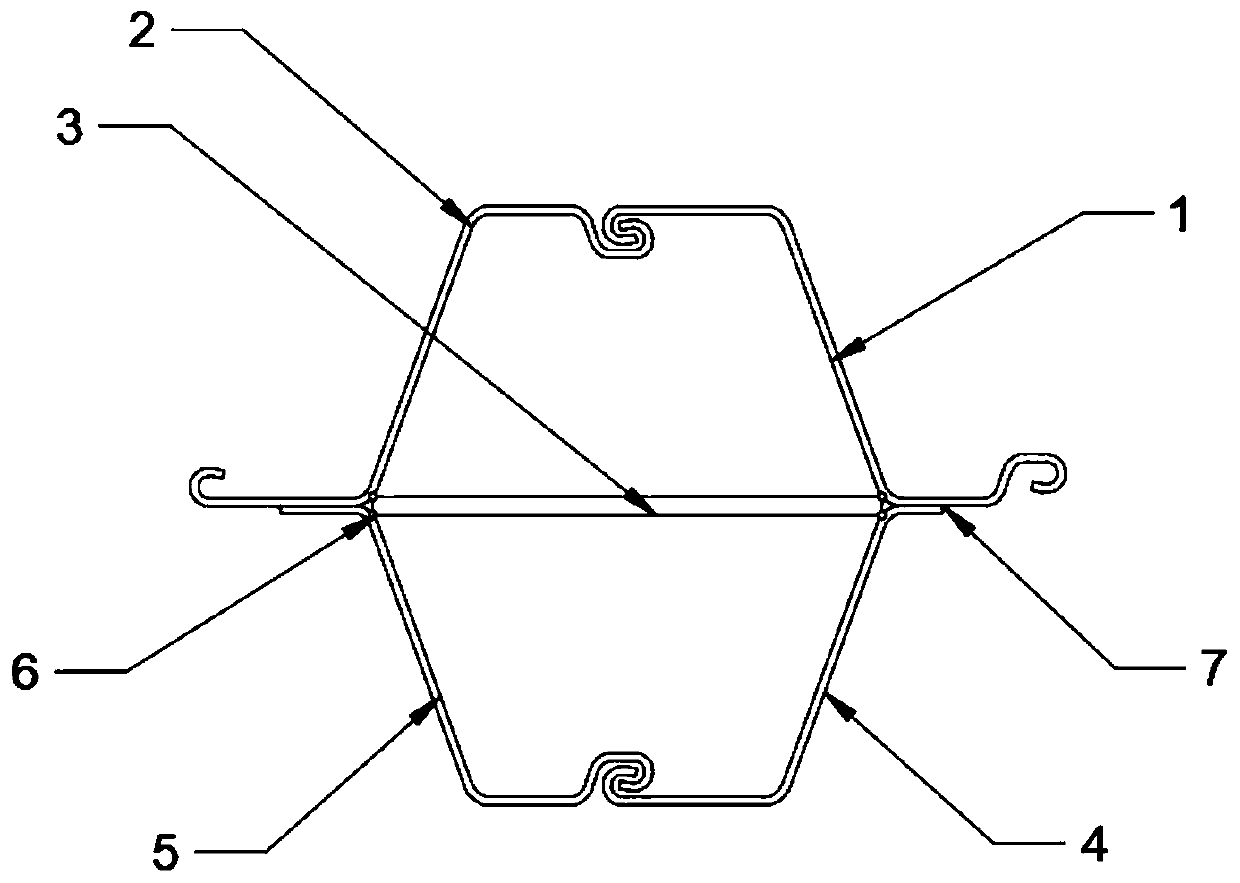

Combined type box steel sheet pile and assembling method thereof

PendingCN111021335AExpand the variety rangeWith extra heavy loadWelding apparatusBulkheads/pilesStructural engineeringSheet pile

The invention discloses a combined type box steel sheet pile and an assembling method thereof, and belongs to the technical field of combined type box steel sheet piles. A first assembly and a secondassembly are placed on the top of a strip-shaped plate through lifting of a travelling crane to be clamped through a third female locking opening and a second male locking opening respectively, spacesbetween the first assembly and the second assembly, and the strip-shaped plate are welded to form a first welding strip, a structure formed by the first assembly, the second assembly and the strip-shaped plate is turned over to enable the strip-shaped plate of the structure to be upward, a fourth assembly and a third assembly are placed on the top of the strip-shaped plate through lifting of thetravelling crane to be clamped through a first female locking opening and a first male locking opening respectively, spaces between the fourth assembly and the third assembly, and the strip-shaped plate are welded to form the first welding strip, the fourth assembly and the second assembly are welded to form a second welding strip, and the third assembly and the first assembly are welded to form the second welding strip.

Owner:南京图信新材料科技有限公司

Method for producing extra-deep drawing cold-rolled steel plate based on ASP process

InactiveCN101941021BReduce manufacturing costMeet needsWork treatment devicesRoll mill control devicesProduction lineAcid washing

The invention discloses a method for producing an extra-deep drawing cold-rolled steel plate based on a sheet billet continuous casting and rolling process in ASP, and belongs to the technical field of rolled steel. After molten steel meeting the component requirement is obtained by adopting molten iron pretreatment, a converter, LF and RH, a hot-rolled substrate is produced by the sheet billet continuous casting and rolling process in the ASP, and the hot-rolled substrate is subjected to acid washing, cold rolling, cover annealing and leveling processes to obtain the extra-deep drawing cold-rolled steel plate. Compared with the prior art, the performance of the produced extra-deep drawing cold-rolled steel plate meets the European standard EN10130-2006, meanwhile, the production cost is reduced, energy is saved and consumption is reduced. The method broadens the variety range of products produced by a sheet billet continuous casting and rolling production line in the ASP, can meet the increasing requirements of the industries of automobiles, home appliances, buildings, transports, light industry and the like for plates, and improves the product competitiveness of enterprises.

Owner:SHANDONG IRON & STEEL CO LTD +1

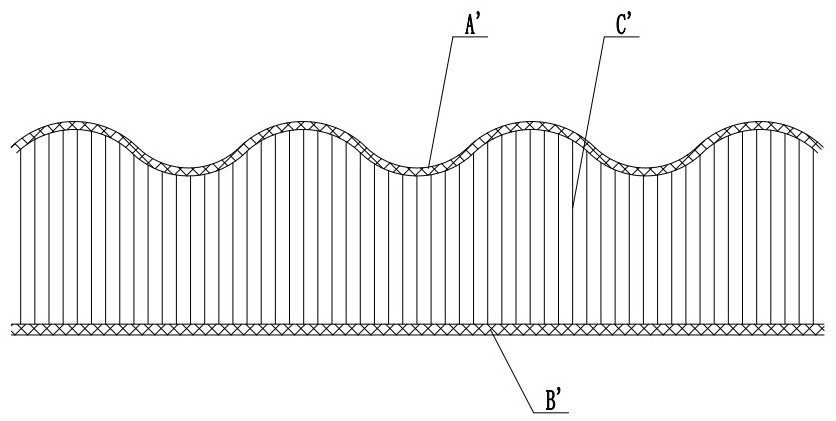

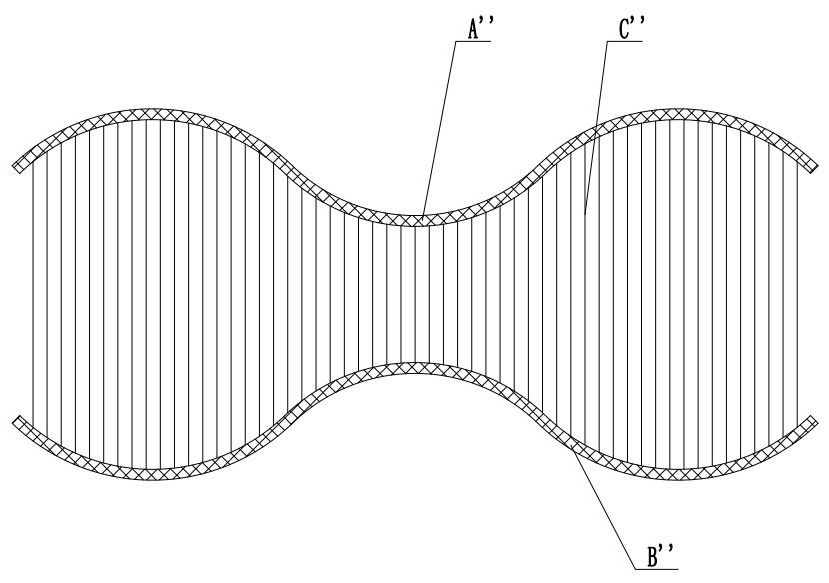

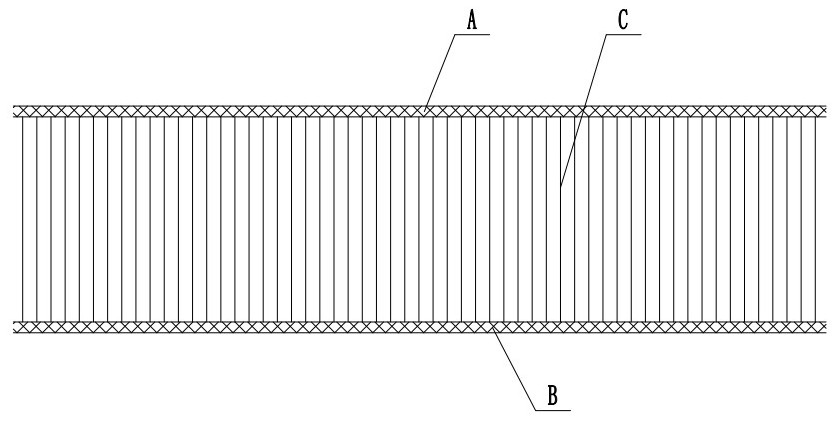

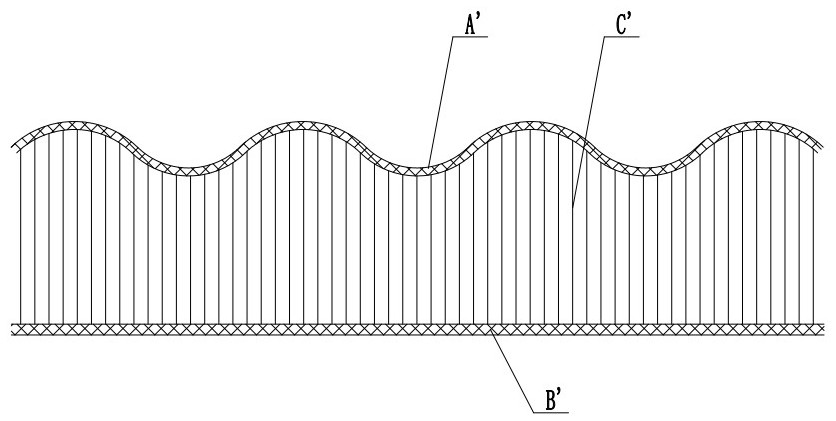

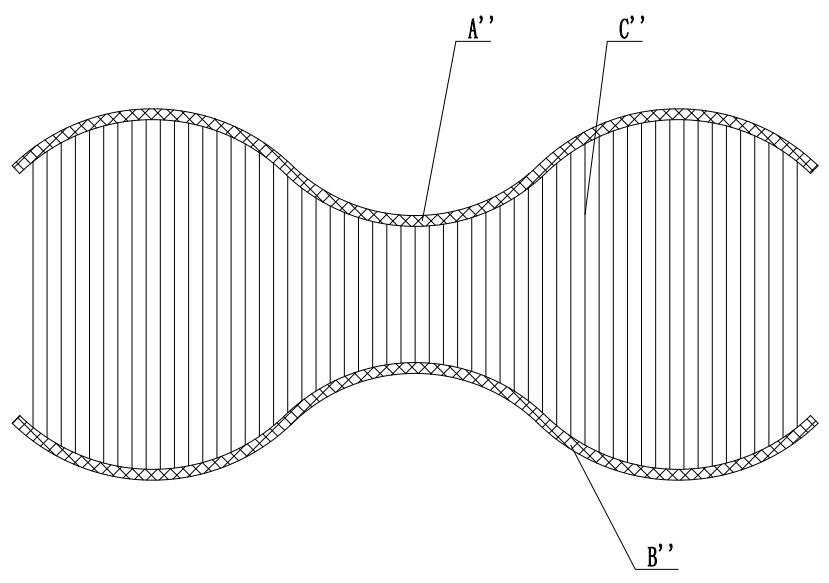

Hollow wiredrawing cloth for weft wiredrawing and manufacturing method thereof

ActiveCN112410972AExpand the range of weavable varietiesExpand the variety rangeMulti-ply fabricsYarnTextile technology

Owner:佛山市晟博纺织有限公司

Hollow brushed cloth drawn in weft direction and manufacturing method thereof

ActiveCN112410972BExpand the range of weavable varietiesExpand the variety rangeMulti-ply fabricsYarnTextile technology

The invention provides a weft-drawn hollow drawing cloth and a manufacturing method thereof, belonging to the technical field of textiles. It includes the upper base fabric, the lower base fabric, the weft drawing that connects the upper base fabric and the lower base fabric, and also includes the auxiliary warp yarns during weaving. The whole production process is as follows: warping, threading reed, calculation according to the height of the upper and lower base fabrics, the length required for weft drawing, and the position where the weft drawing is consolidated on the upper and lower base fabrics, weaving, glue coating, water-soluble ,tidy. The present invention has simple requirements for equipment, and only needs to be used on a 1×3 single-sided multi-shuttle box shuttle loom when the upper base fabric and the lower base fabric are flat and double-sided wavy or one side is flat and the other side is wavy. Weaving can be completed with the help of auxiliary warp yarn, which is a common water-soluble vinylon yarn, which is cheap and does not pollute the environment. It does not affect the quality of gluing, and the process flow is smooth.

Owner:佛山市晟博纺织有限公司

Portable juicing cup based on TRIZ and using method

The invention provides a portable juicing cup based on TRIZ. The cup comprises a cup base, a middle cup body, an upper cup body and a cup cover, the middle cup body, the upper cup body and the cup cover are detachably connected, the cup base comprises an upper containing cavity and a lower containing cavity which are separated, a lithium battery and a control circuit board are arranged in the lower containing cavity, a plug-in port and a power utilization port are formed in the periphery of the lower containing cavity, and a cup base cup body is arranged in the upper containing cavity. A cup base shell is arranged outside the upper containing cavity, and a motor and a reamer are arranged in the cup base shell. The middle cup body and the upper cup body can be contained in a cavity between the cup base cup body in the upper containing cavity of the cup base and the cup base shell, and the cup cover threads on the cup cover are connected with the threads of the cup base shell to form a juicing cup containing body. The juicing cup has the advantages that the juicing cup is simple in structure, processing and manufacturing of juice, pulp, powder and the like of different kinds of fruits, vegetables and even traditional Chinese medicinal materials can be achieved, and the effect that one cup has multiple purposes is achieved for a user; and meanwhile, the cup body can be screwed, disassembled and assembled, is leakage-proof, is easy to clean and maintain, and is convenient to carry and store.

Owner:FUJIAN OSPRING TECH & DEV

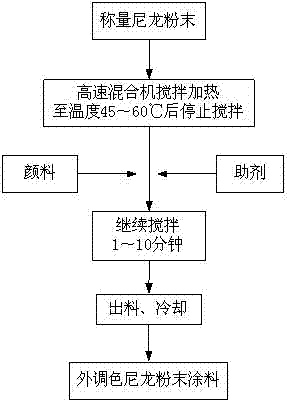

Exterior color-mixed nylon powder coating and preparation method thereof

ActiveCN102796450BExtended service lifeExpand the variety rangePowdery paintsPolyamide coatingsTest sampleColor mixing

The invention discloses an exterior color-mixed nylon powder coating and a preparation method thereof, belonging to the field of preparation of nylon powder coatings. The exterior color-mixed nylon powder coating is formed by mixing nylon powder, pigments and auxiliaries, and the weight ratio of the nylon powder to the pigments to the auxiliaries is 100:(0.1-15):(0.01-15). The preparation method comprises the following steps: firstly, heating the nylon powder with the need of color mixing to 45-60 DEG C through a high-speed mixing machine, then adding the pigments and the auxiliaries according to the weight ratio, performing high-speed mixing, and adhering the pigments to nylon powder particles to prepare the exterior color-mixed nylon powder coating of a target color. According to the preparation method of the exterior color-mixed nylon powder coating, disclosed by the invention, adverse factors of color mixing of a traditional process are overcome, and the preparation method has the advantages of simplicity, easiness in operation, fast color-mixing speed, convenience in cleaning, mass production and test sample preparation; and the prepared exterior color-mixed nylon powder coating has the advantages of uniform color dispersion, dense and firm coating and good using performances.

Owner:宣城徽元材料科技有限公司

Production process of snow wash denim fabric with warm-keeping function

InactiveCN105774082AWith heat preservation functionShrinkage stableSucessive textile treatmentsLayered productsDenimShrinkage rate

The invention discloses a production process of a snow wash denim fabric with a warm-keeping function. The production process specifically comprises the following steps: weaving a fabric, feeding the fabric, performing water saturation soaking, performing weft finishing, overfeeding, baking, performing dry-grinding by using pumice, matching, washing, neutralizing, coating a softening agent, fixing the shape, and molding. By adoption of the production process, the phenomenon that a denim fabric is faded can be effectively reduced, the shrinkage rate and the gram weight stability of the denim fabric can be ensured, the denim fabric is good in molding property, and an optimal fabric condition is created for clothes production.

Owner:TAICANG QIDE GARMENT

A Coke Pushing Process Control Method for Reducing the Coking Pushing Current

The invention discloses a coke pushing process control method for reducing the coke pushing current in the coking oven, which comprises the following steps: 1) After the coke in the coking oven coking process is mature, the furnace door is opened on the left, upper and right walls of the coking oven wall Carry out high-pressure oxygen purging separately until the graphite on the wall is burned; 2) After the oxygen purging is completed, align the coke pusher rod with the coke in the coke oven and gradually move towards the coke. After an instant stop for 1s, continue to advance at the speed of the first gear. When moving forward at the first gear speed for 1‑1.2s, switch to the second gear. After moving forward at the second gear speed for 1‑1.2s, switch to the third gear. After moving forward for 6‑7s, switch to gear 4, and continue to push the coke to push the coke out of the carbonization chamber.

Owner:BAOSHAN IRON & STEEL CO LTD

Hydrogen hot metal desulfurization method

The invention provides a hydrogen hot metal desulfurization method, which adopts a hydrogen top blowing method combined with a two-step process of injection pressurization-recovery decompression to carry out efficient desulfurization reaction of molten iron and recovery of gas after reaction. Firstly, the hydrogen gas is subjected to compression treatment, and the hydrogen gas is blown into the molten iron in the molten iron tank under the predetermined blowing pressure condition; after performing the top blowing treatment for 10 to 20 minutes, the molten iron fully reacts with the pretreated hydrogen gas to form hydrogen sulfide gas; then, decompress and pump the molten iron tank, adjust the pressure in the molten iron tank to a predetermined decompression pressure, recover the hydrogen sulfide gas, and obtain desulfurized molten iron. Compared with the traditional chemical desulfurizer molten iron desulfurization method, the method provided by the invention combines the top blowing method with injection pressurization-recovery and decompression treatment to realize slag-free gasification desulfurization, has excellent desulfurization effect, and is economical and environmentally friendly. Advantages, used for the production of low-sulfur, ultra-low-sulfur high-quality steel.

Owner:WUHAN UNIV OF SCI & TECH

A kind of ultra-deep drawing cold-rolled enamel steel produced by asp double-link process and its manufacturing method

The invention belongs to the technical field of metal material manufacturing, and in particular relates to super deep-drawing cold-rolled enamel steel produced by an ASP diplex process and a manufacturing method thereof. The enamel steel comprises the following components in percentage by weight: less than or equal to 0.005% of carbon, less than or equal to 0.030% of silicon, 0.10 to 0.35% of manganese, less than or equal to 0.015% of phosphorus, 0.015 to 0.035% of sulfur, 0.015 to 0.050% of acid dissolved aluminum, 0.070 to 0.10% of titanium, 0.0040 to 0.0070% of nitrogen, and the balance of iron and unavoidable impurities. The manufacturing method comprises the following steps of: (1) smelting by a converter, (2) refining by an LF (ladle furnace), (3) vacuum-refining by an RH furnace, (4) continuously casting and rolling, (5) washing by acid, cold-rolling, annealing and flattening. By adoption of the LF and RH diplex process, the mass production of the super deep-drawing cold-rolled enamel steel is successfully realized on an ASP production line.

Owner:JIGANG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com