Hydrogen hot metal desulfurization method

A technology for desulfurization of molten iron and hydrogen, applied in the field of desulfurization of molten iron, can solve the problem that desulfurization efficiency has not been greatly improved, and achieve the effects of excellent desulfurization effect, expansion of varieties, and simplification of steelmaking operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

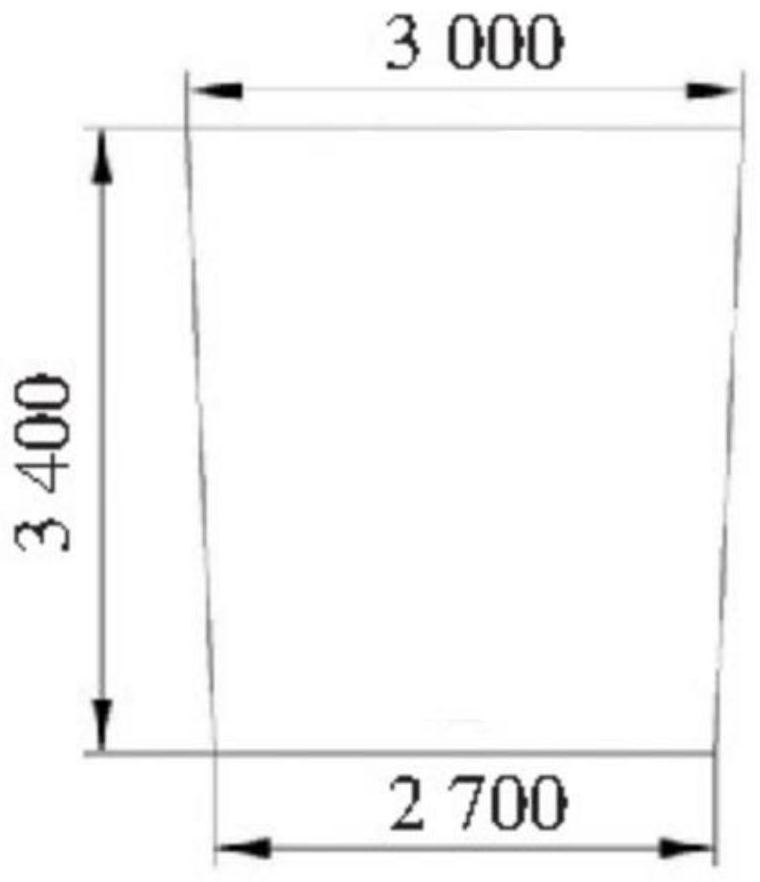

[0036] Embodiment conditions: molten iron temperature 1330 ℃, initial sulfur content of 0.035%, the target was 0.003% sulfur content, iron 110T tank capacity (such as figure 1 Indicated.

[0037] Hydrogen gas desulphurization method comprising the steps of:

[0038] Sl, hydrogen gas is compressed to give pretreated hydrogen; Then, under conditions of injection pressure of 50MPa, by a top blowing lance in a top-blown from the blowing holes manner, the hydrogen gas in the pretreatment 40m 3 / H flow rate of top-blown blown into the molten iron in the ladle closed; at the injection pressure, the molten iron to achieve a predetermined high-pressure state. Wherein said top blowing lance disposed at the center position of the hot metal surface of the iron in the tank; and the blow hole of the hot metal surface from a height of 200mm; the blow hole of the nozzle diameter 8mm.

[0039]S2, the pretreatment step S1 for the top-blowing hydrogen treatment after 10min, the reaction with the mo...

Embodiment 2-5

[0047] Example 1 except that: the injection pressure different settings in step S1, the other steps are the same as in Example 1, are not repeated here.

[0048] Example Spray pressure Blowing method Desulfurization effect Example 1 50MPa Top-blowing 83.49% Example 2 2MPa Top-blowing 80.05% Example 3 20MPa Top-blowing 81.11% Example 4 80MPa Top-blowing 85.76% Example 5 120MPA Top-blowing 88.92% Contrast 1 / Top-blowing 38.76% Contrast 2 / Bottom blowing 43.56%

[0049] From the above table it can be seen, with increasing injection pressure, desulfurization efficiency showed a gradual upward trend. This is mainly due to: hydrogen by compression processing, the high-pressure hydrogen gas during top-blowing through the molten iron, increases the solubility of hydrogen in the molten iron, while increasing the hydrogen outlet discharge speed, increase the hot metal sulfur and hydrogen the chance of contact, so that a more...

Embodiment 6-8

[0053] Example 1 differs in that: the top-blowing different flow rate settings are the same as in Example 1 and the other steps are not repeated here.

[0054] Example Top blow traffic Desulfurization efficiency Example 1 40M 3 / h

[0055] With the reduced flow rate of top-blowing, top blowing lance near wall region of turbulent kinetic energy and the speed is gradually reduced, the gas tank also increased the residence time in the molten iron, sputtering is reduced. However, too small flow rate of top-blown molten iron against agitation tank hydrogen flow field.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com