Method for processing rare earth photochromic color flash air-jet vortex spun yarns

A photochromic and processing method technology, applied in the direction of continuous winding spinning machine, yarn, spinning machine, etc., can solve the problems of novel, changeable and dreamy air-jet vortex yarn products that have never been seen before, and avoid dyeing. Difficult, uniform flashing effect, short technological process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

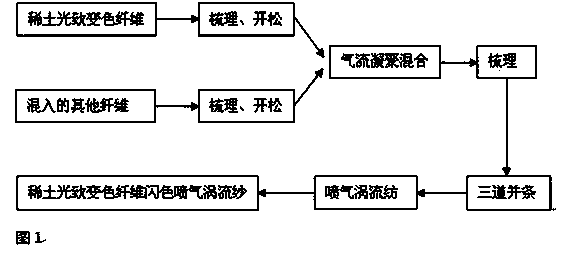

[0029] figure 1 It is a schematic diagram of the processing flow of the rare earth photochromic fiber light-colored air-jet vortex yarn in this embodiment. like figure 1 As shown, the rare earth photochromic polyester fiber with a content of 5% and the viscose natural color fiber with a content of 95% are carded and loosened respectively, and then coagulated and mixed by airflow, and finally the carding and three drawing processes are completed. Air-jet vortex spinning technology obtains 40 British-count rare earth photochromic fiber flashing color air-jet vortex yarn after drawing, twisting, winding, winding and other processing procedures. and other fields.

[0030] In this example, the rare earth photochromic polyester fiber is prepared by doping with rare earth oxides. The carding process adopts the technological principle of "light weight, low speed, large gauge, and small tension" to reduce fiber damage, so that the fibers can be fully carded and well transferred; the...

Embodiment 2

[0033] Comb and open the rare earth photochromic viscose fiber with 20% content, 5% metal wire fiber, 30% modal natural color fiber, and 45% light gray polyester fiber, and then use it under the condition of spraying antistatic agent The air flow is condensed and mixed (the workshop temperature is controlled at 26±2°C, and the relative humidity is controlled at 55±4%, so as to reduce the phenomenon of winding rubber rollers and aprons in the subsequent process), and finally complete the carding and three drawing frames, and finally use Air-jet vortex spinning technology obtains 30 lbs rare earth photochromic fiber flashing color air-jet vortex yarn after drawing, twisting, winding, winding and other processing procedures. The yarn prepared in this embodiment can be used for dyed fabrics, high-end fashion , Evening dresses and other products are under development.

[0034] In this example, the rare earth photochromic polyester fiber is prepared by hybridization of rare earth co...

Embodiment 3

[0037] The photochromic polyester fiber with a content of 60% rare earth and 40% natural fiber of bamboo pulp are carded and loosened respectively, and then condensed and mixed by airflow under the condition of spraying antistatic agent (the workshop temperature is controlled at 25±1°C, The relative humidity is controlled at 53±4% to reduce the phenomenon of winding cots and aprons in the back pass), and finally complete the carding and three drawing frames, and finally use the air-jet vortex spinning technology to go through drafting, twisting, winding, After winding and other processing steps, 30 lbs. rare earth photochromic fiber flashing air-jet vortex yarn was obtained. The yarn prepared in this embodiment can be used in the development of products such as colored fabrics, trademarks, patterns and decorative fabrics.

[0038] In this example, the rare earth photochromic polyester fiber is prepared by bonding with rare earth inorganic salts. The carding process adopts the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com