Method for producing seamless steel pipe with reversible reciprocating periodic time hot rolling technique

A technology of seamless steel pipe and process, applied in the field of manufacturing seamless steel pipe, can solve the problems of uneven metal deformation, low-plastic alloy steel cracking, limited feeding amount, etc., to expand the range of varieties, improve rolling efficiency, improve economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

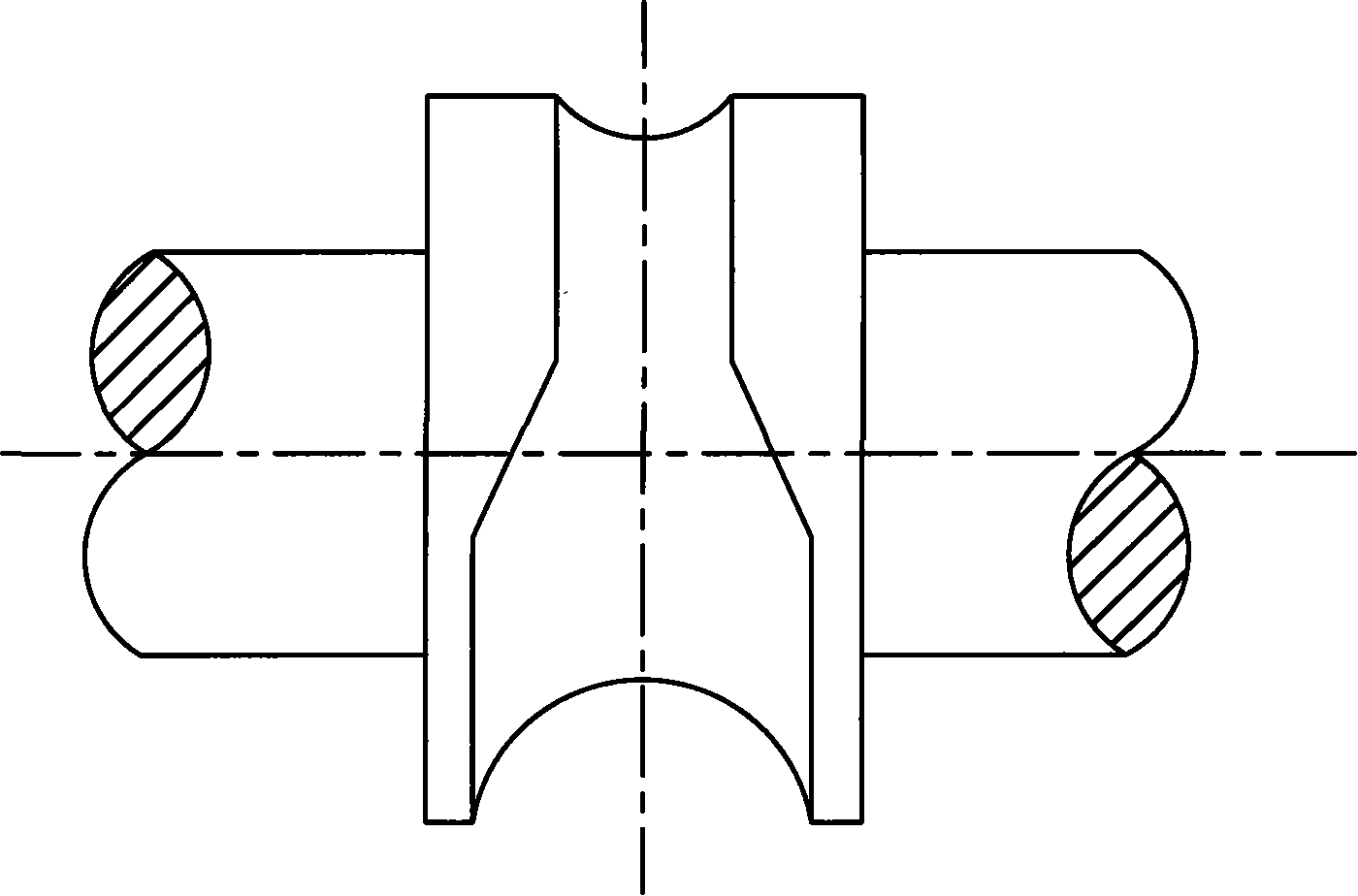

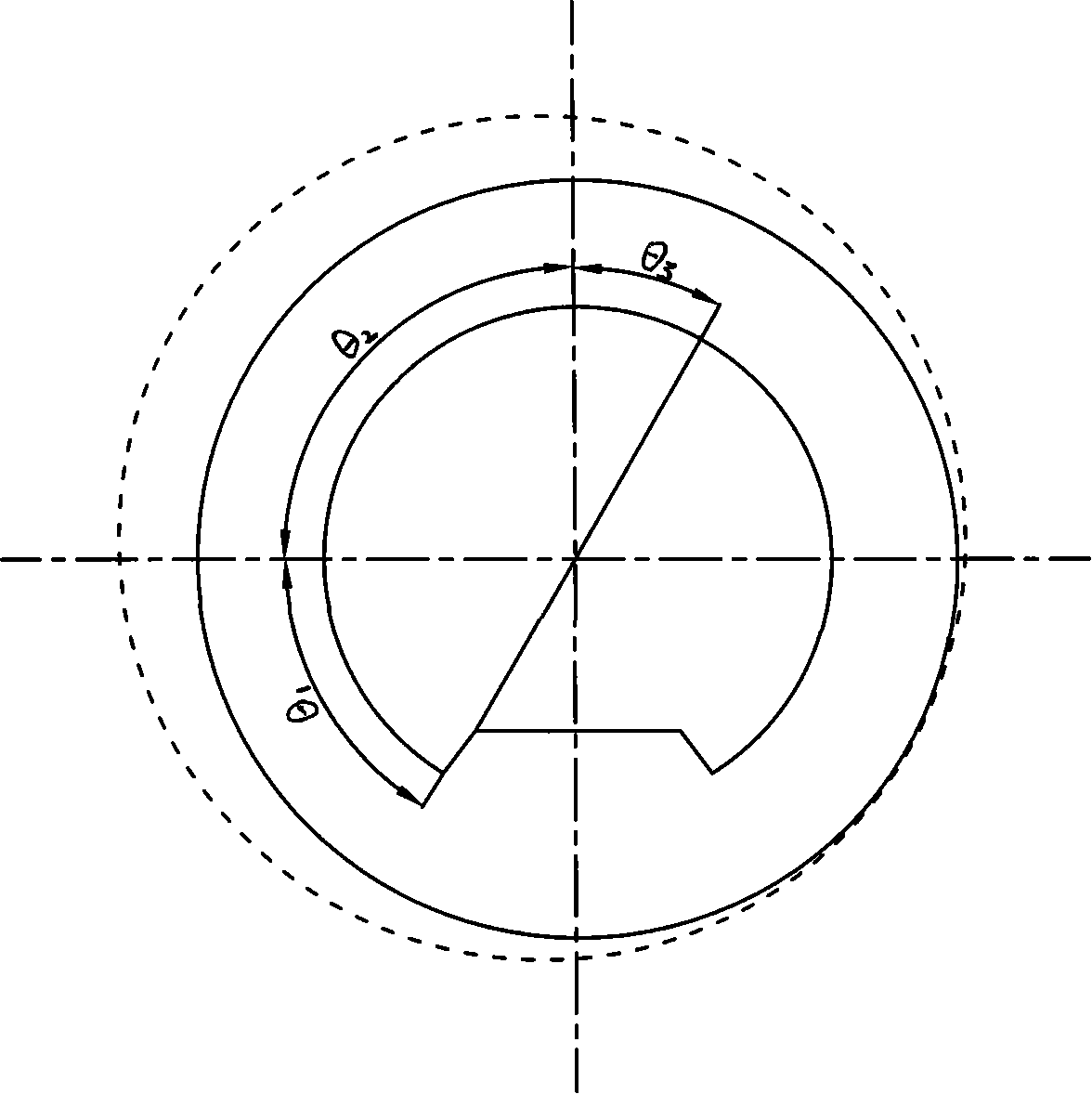

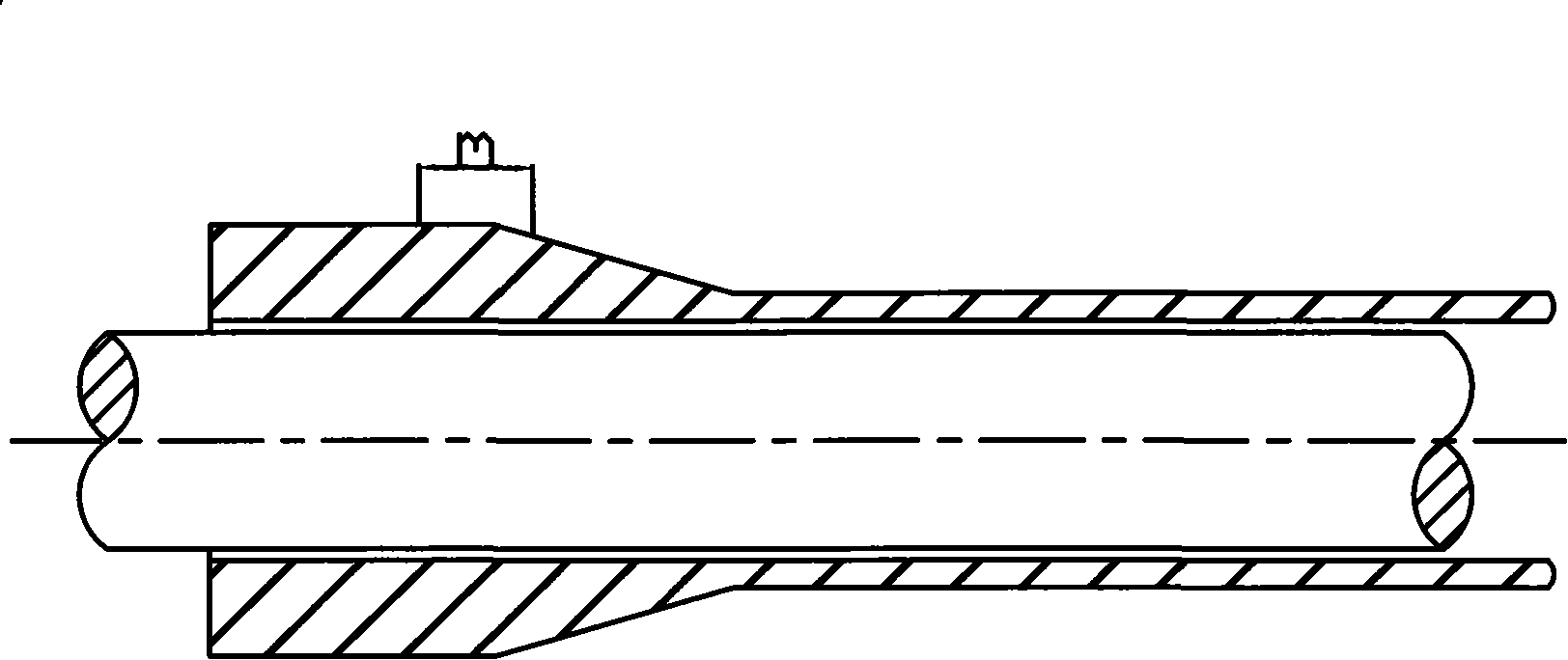

[0021] The reversible reciprocating periodic hot rolling mill adopted in the present invention comprises a plurality of stands arranged along the moving direction of the rolled piece, and two groove-shaped rolls are arranged oppositely on each stand, and the rolls are separated between adjacent stands. The rolling direction is staggered by 90 degrees to alternately arrange the pass of the rolls. The control mechanism is connected with the power equipment of the pass rolls on each stand to control the rotation of the rolls. The shape of each cross section of the pass of the rolling mill is the same, which is determined by It is composed of three sections of arcs. At both ends of the hot rolling mill, there is also an overturning mechanism that rotates the rolled piece at a certain angle after it has been rolled once. The reciprocating periodic rolling of pieces.

[0022] In the hot rolling state, the passes of the upper and lower rolls each have two circular arc segments that d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com