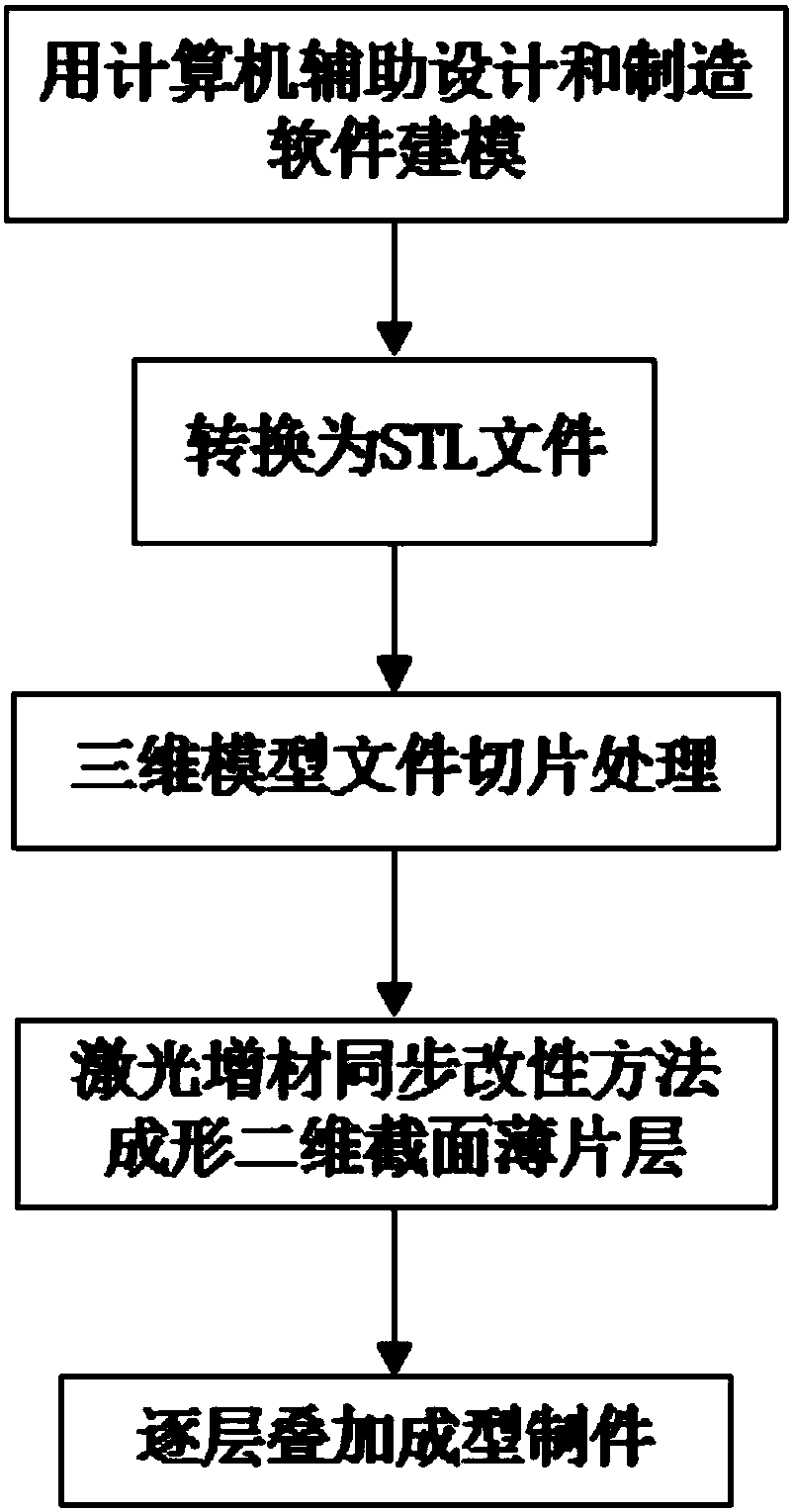

Method for conducting synchronous modification on powder-feeding type laser additive manufacturing manufactured workpiece

A technology for laser additive materials and parts, applied in the field of rolling process, can solve the problems such as difficulty in guaranteeing the qualified rate of generated products, increasing manufacturing costs, complicated process, etc., reducing the surface roughness of parts, improving the density, The effect of improving rolling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

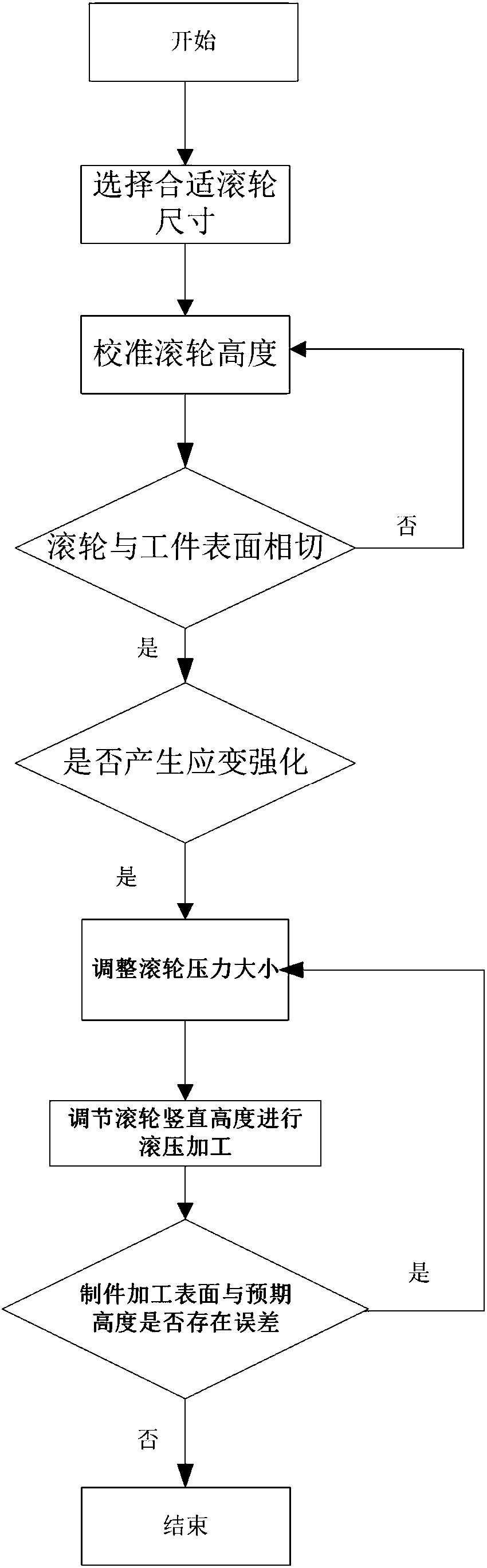

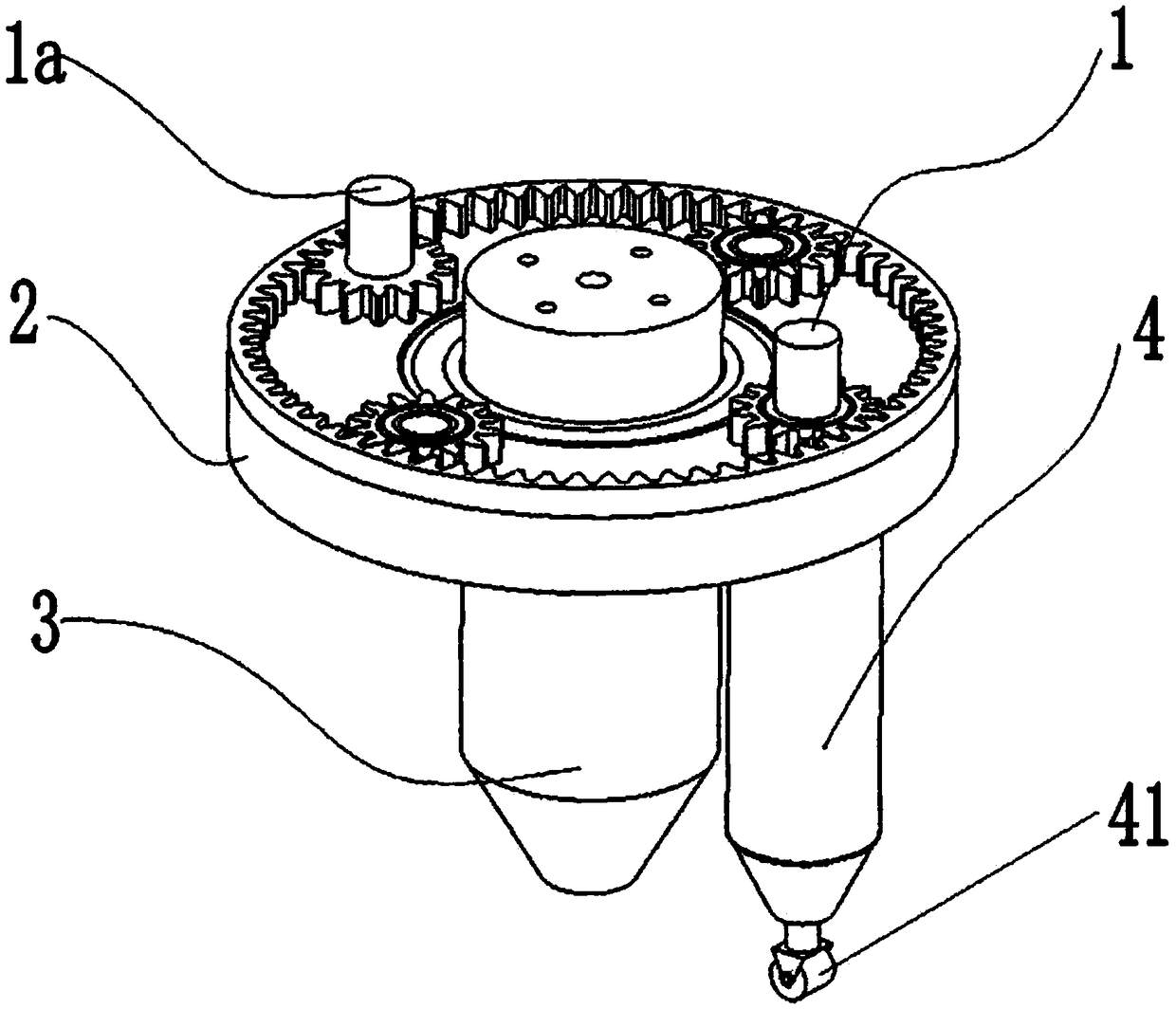

[0058] In this example, the 3D additive manufacturing of flat parts of titanium alloy powder is used to realize simultaneous modification, and the rolling process is used to strengthen the surface of 3D printed parts, improve the hardness and strength, and refine the internal structure of metal materials. See Figure 5 , fused and absorbed material defects under the pressed surface, improving the compactness of the workpiece. The selected titanium alloy powder particles are 50-100 μm powder particles. Taking the original surface roughness Rz=2 μm, and the titanium alloy material is selected as a common rolling force of 500-1000N as an example, the diameter of the rolling head selected in this embodiment is 5mm; The above-mentioned laser is a fiber laser, the power of the laser is P=4000W, the scanning speed is V=12mm / s, the single track width is 4mm, and the overlapping rate is 30-40%. Figure 5 Among them, 5-peak; 6-trough; 7-filler; d1-diameter before rolling; d2-diameter af...

Embodiment 2

[0060] The choice of rolling method can be determined according to the shape of the metal part to be printed. For example, the printed metal parts are single-layer metal crafts or the upper surface of 3D printed parts, which have high requirements for the surface quality of the workpiece.

[0061] The steps in this embodiment 2 are the same as in embodiment 1, except that the specific process parameters are slightly different, the selected powder particles are 50-100 μm powder particles, and the diameter of the selected rolling head is 6 mm; the laser is a CO2 laser, the The laser power P=2000W, the scanning speed V=8mm / s, the single track width is 4mm, and the overlapping rate is 30-40%.

[0062] Choose rollers with lower rolling force, feed rate and lower surface roughness according to the desired effect. In the specific implementation mode, the strength, stress and design requirements of the metal parts in all directions should be considered comprehensively, and the synchr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com