Combined type box steel sheet pile and assembling method thereof

An assembly method and a technology of steel sheet piles, which are applied to sheet pile walls, buildings, manufacturing tools, etc., can solve the problems that cannot meet the needs of large-scale port construction, and achieve the effects of simple structure, convenient manufacture, and expanded variety range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

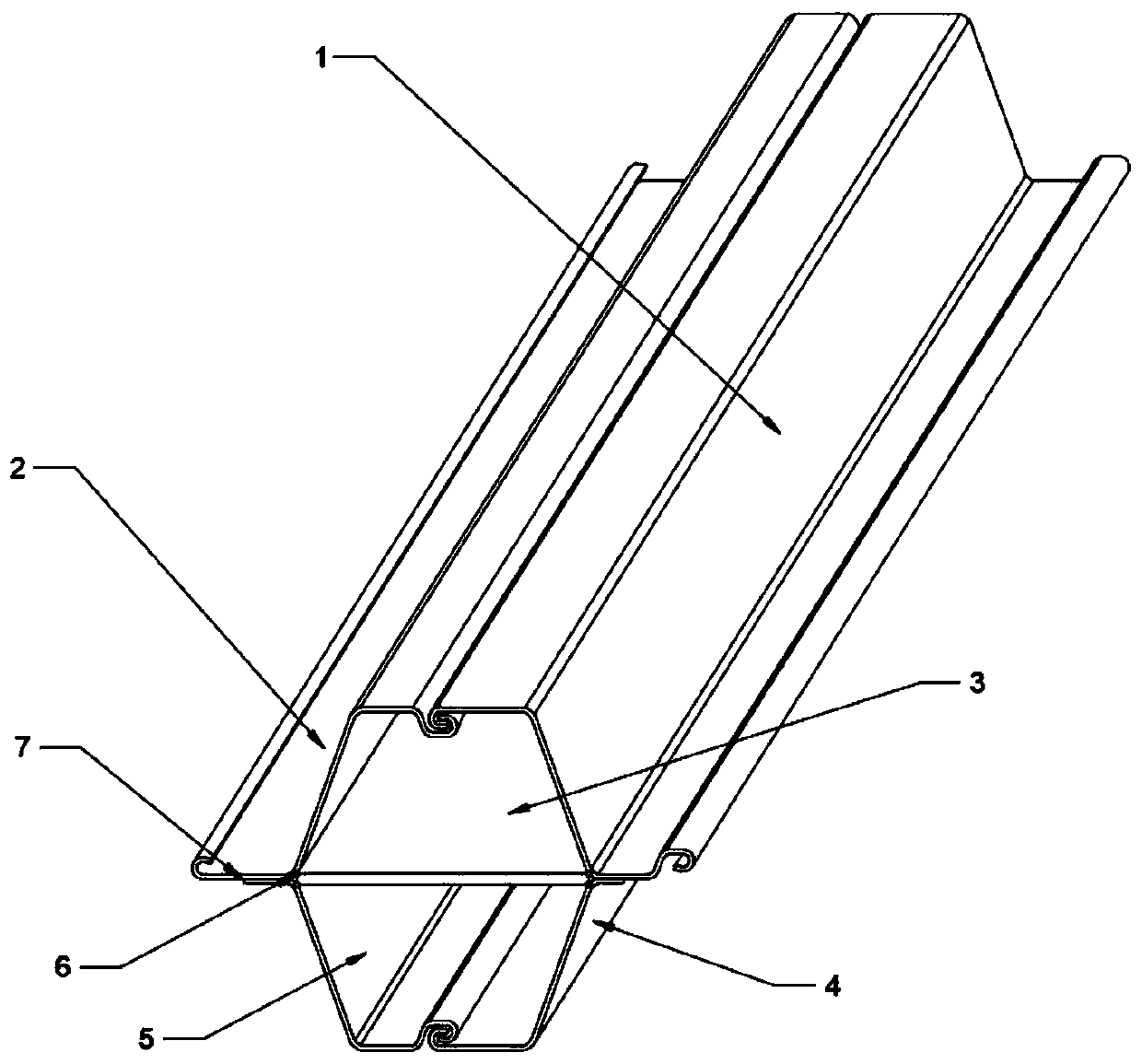

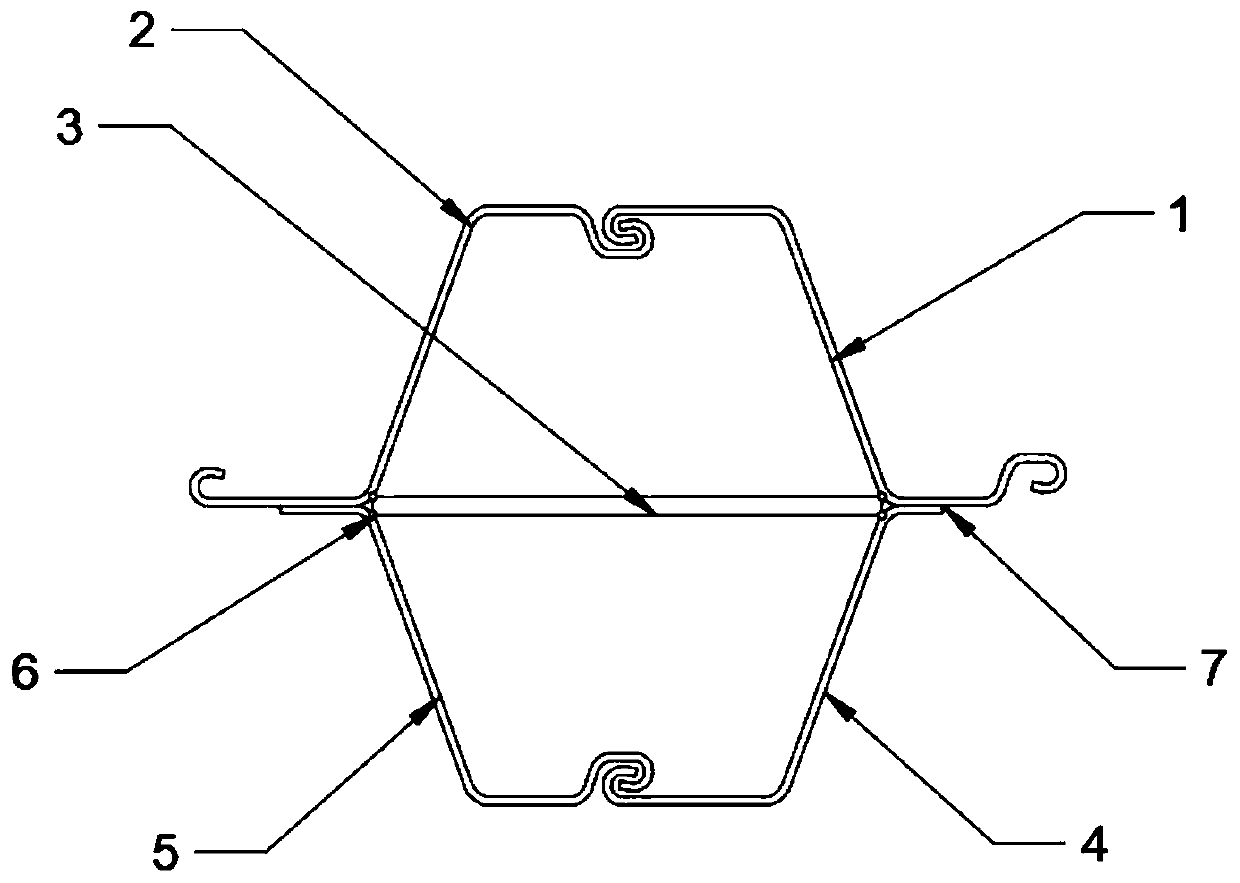

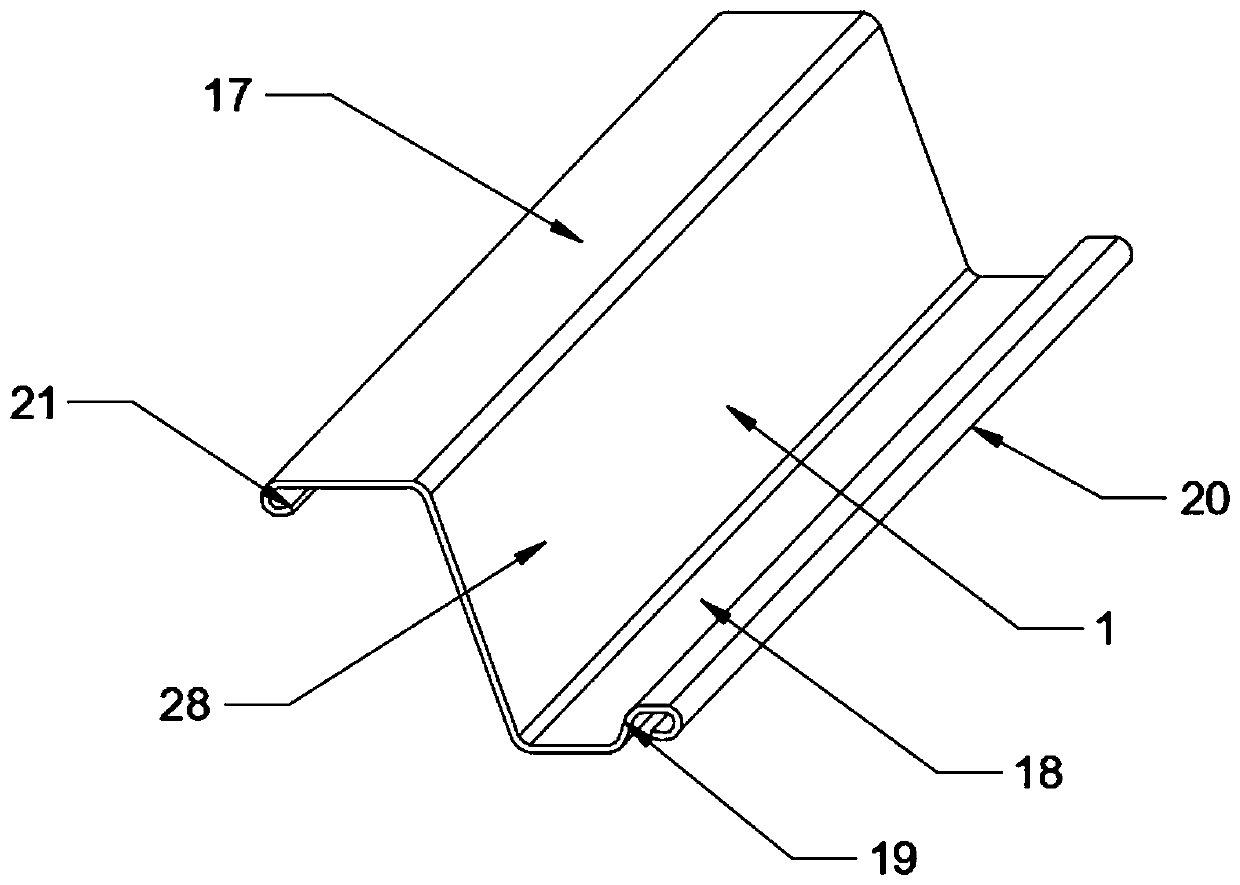

[0033] like Figure 1-Figure 7 As shown, a combined box steel sheet pile provided in this embodiment includes a strip plate 3 and a second component 2 welded on the top side of the strip plate 3 through the first welding strip 6, and the top of the strip plate 3 The other side is welded with the first component 1 by the first welding strip 6, and the fourth component 5 is welded on one side of the bottom of the strip plate 3 by the first welding strip 6, and the other side of the bottom of the strip plate 3 is welded by the first welding strip 6. The strip 6 is welded with the third component 4, the top of the fourth component 5 is in contact with the bottom of the second component 2 and welded by the second welding strip 7, the top of the third component 4 is in contact with the bottom of the first component 1 and passed through the second The welding strip 7 is welded, the first component 1 and the second component 2 are engaged with each other, and the fourth component 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com