Exterior color-mixed nylon powder coating and preparation method thereof

A nylon powder coating and nylon powder technology, applied in powder coating, polyamide coating, coating, etc., can solve the problems of poor coloring quality, uneven color of nylon powder coating, easy delamination of pigment and powder coating, etc. The effect of dense and firm layer, improved coloring strength and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

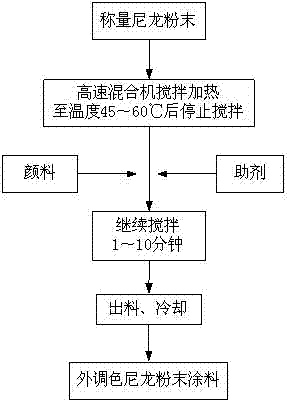

[0021] Such as figure 1 Shown a kind of exterior color nylon powder coating and preparation method thereof, its steps are as follows:

[0022] 1) Put 50 kg of colorless and transparent nylon 1012 modified powder prepared by the solvent method into a high-speed mixer, seal it, start stirring, and control the stirring speed at 1000 rpm, and stop stirring when the temperature of the material rises to 45°C;

[0023] 2) Weigh 100 grams of pigment, the selected pigment is carbon black among inorganic pigments, and the particle size is 10-20 nanometers. Take by weighing 20 grams of auxiliary agent, the selected auxiliary agent is polyethylene micropowder wax; pigment and auxiliary agent are added in the high-speed mixer;

[0024] 3) Continue to turn on the stirring, the speed is 1000 rpm, and stir for 1 minute;

[0025] 4) Discharge, cool the material to normal temperature, and then get the finished black nylon powder coating.

Embodiment 2

[0027] A kind of exterior color nylon powder coating of the present invention and preparation method thereof, its steps are as follows:

[0028] 1) Put 50 kg of colorless and transparent nylon 1212 powder prepared by extrusion modification-cryogenic crushing process into a high-speed mixer, seal it, start stirring, and control the stirring speed at 1200 rpm. When the temperature of the material rises to 50 ° C , stop stirring;

[0029] 2) Weigh 500 grams of pigment, the selected pigment is titanium dioxide in inorganic pigments, the particle size is 200-400 nanometers, the selected organic pigment is phthalocyanine blue of phthalocyanine, the weight ratio of titanium dioxide and phthalocyanine blue is 4:1 . Take by weighing 50 grams of auxiliary agent, the selected auxiliary agent is polyethylene micropowder wax;

[0030] 3) Continue to turn on the stirring at a speed of 1200 rpm and stir for 2 minutes;

[0031] 4) Discharge, cool the material to normal temperature, and the...

Embodiment 3

[0033] A kind of exterior color nylon powder coating of the present invention and preparation method thereof, its steps are as follows:

[0034] 1) Put 50 kg of colorless and transparent nylon 1012 powder prepared by the solvent method into a high-speed mixer, seal it, start stirring, and control the stirring speed at 900 rpm, and stop stirring when the temperature of the material rises to 45°C;

[0035] 2) Weigh 60 grams of pigments, the selected pigments are titanium dioxide and carbon black in inorganic pigments, no organic pigments are added, the weight ratio of titanium dioxide to carbon black is 1:5, and the particle sizes are 200-400 nanometers and 10-20 nanometers respectively. Nano. Take by weighing 20 grams of auxiliary agent, the selected auxiliary agent is polyethylene micropowder wax;

[0036] 3) Continue to turn on the stirring at a speed of 900 rpm and stir for 3 minutes;

[0037] 4) Discharge, cool the material to room temperature, and then get the finished g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com