Hollow brushed cloth drawn in weft direction and manufacturing method thereof

A production method and technology of brushed cloth, applied in textiles and papermaking, multi-strand fabrics, textiles, etc., to achieve the effects of expanding the range of varieties, improving production efficiency, and simplifying weaving equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

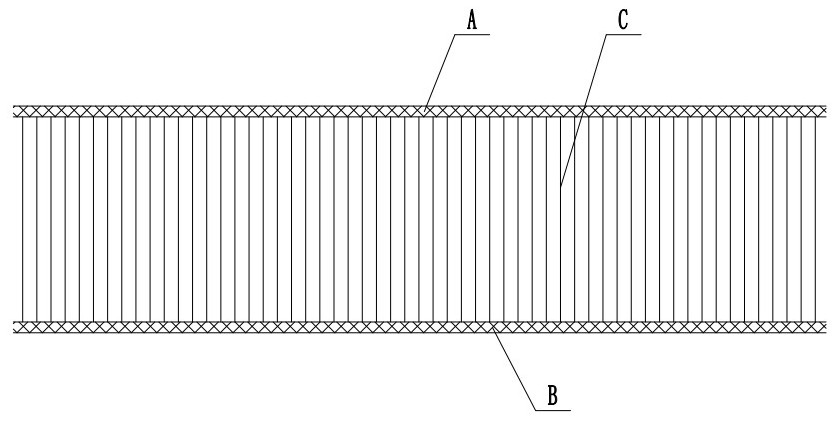

[0089] The production of the weft-drawn planar hollow brushed fabric with a height of 90cm in the upper and lower base fabrics:

[0090] Step 1. Warp the high-strength industrial polyester strong warp yarn of the upper base fabric, the water-soluble yarn of the middle auxiliary warp yarn, and the high-strength industrial polyester strong warp yarn of the lower base fabric on the upper weaving shaft, the middle weaving shaft, and the lower weaving shaft of the loom respectively according to the process requirements. axis.

[0091] Step 2, according to the technical requirements, the upper layer of high-strength industrial polyester warp yarns, the middle layer of auxiliary warp yarns, and the lower layer of high-strength industrial polyester warp yarns are threaded into heddle reeds in sequence.

[0092] Step 3, dividing the warp reed width evenly into 1-101 points according to the weaving shrinkage rate. The distance between points is 1.5cm.

[0093] Step 4.1, let the first ...

Embodiment 2

[0109] By analogy, if the embodiment is a 60cm-high upper and lower weft drawing cloth, and the distance between points is 1.5cm, then only the third shuttle needs to be spanned from the first point of the upper warp to the 21st point of the middle auxiliary warp There are 40 points back and forth, which is 60cm high.

Embodiment 3

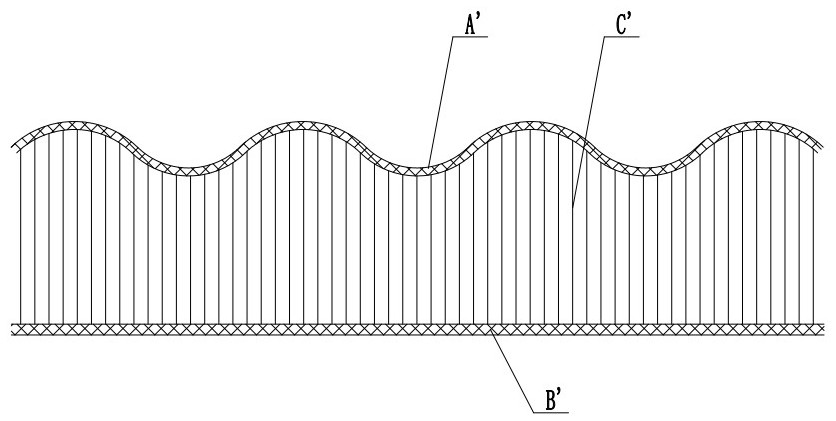

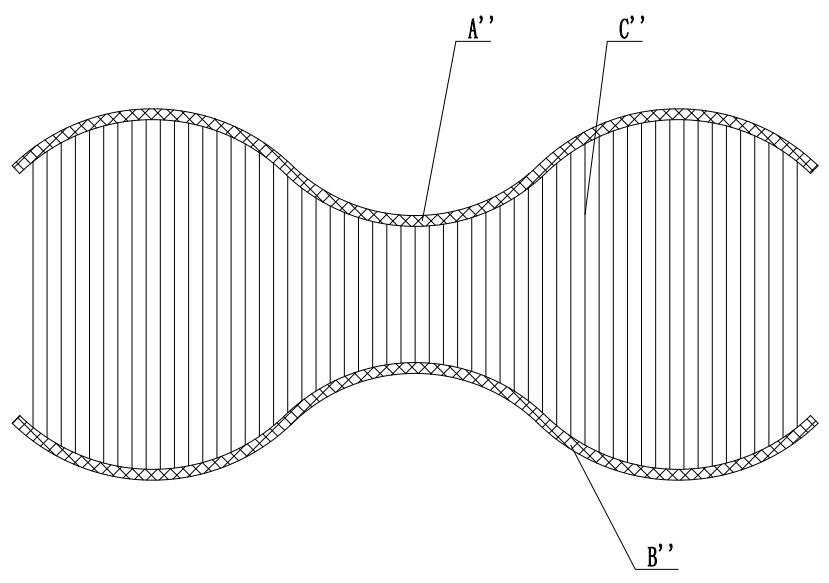

[0111] Embodiment If one side is planar, one side is wavy, or two sides are wavy, then the third shuttle only needs to calculate the required length from the upper point to the lower point and divide it by 2, so that the third shuttle can span this distance Interweave back and forth with the auxiliary warp yarns of the middle layer and then consolidate and interweave with the upper and lower base fabrics. Then, when applying glue, apply superglue for flat and super elastic glue for waves. Of course, the wavy base fabric is formed by interweaving elastic strong warp and weft yarns, while the planar one is still formed by interweaving strong warp and weft yarns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com