Electromagnetic/ultrasound compound outfield continuous casting and rolling device

An ultrasonic and field technology, applied in the field of continuous casting and rolling of aluminum alloy cast-rolled slabs, can solve the problems of unstable quality and uneven surface corrosion in the production of cans slabs, automobile plates, cast-rolled plates, etc., and improve various Anisotropy, improvement of coagulation structure, improvement of structure and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

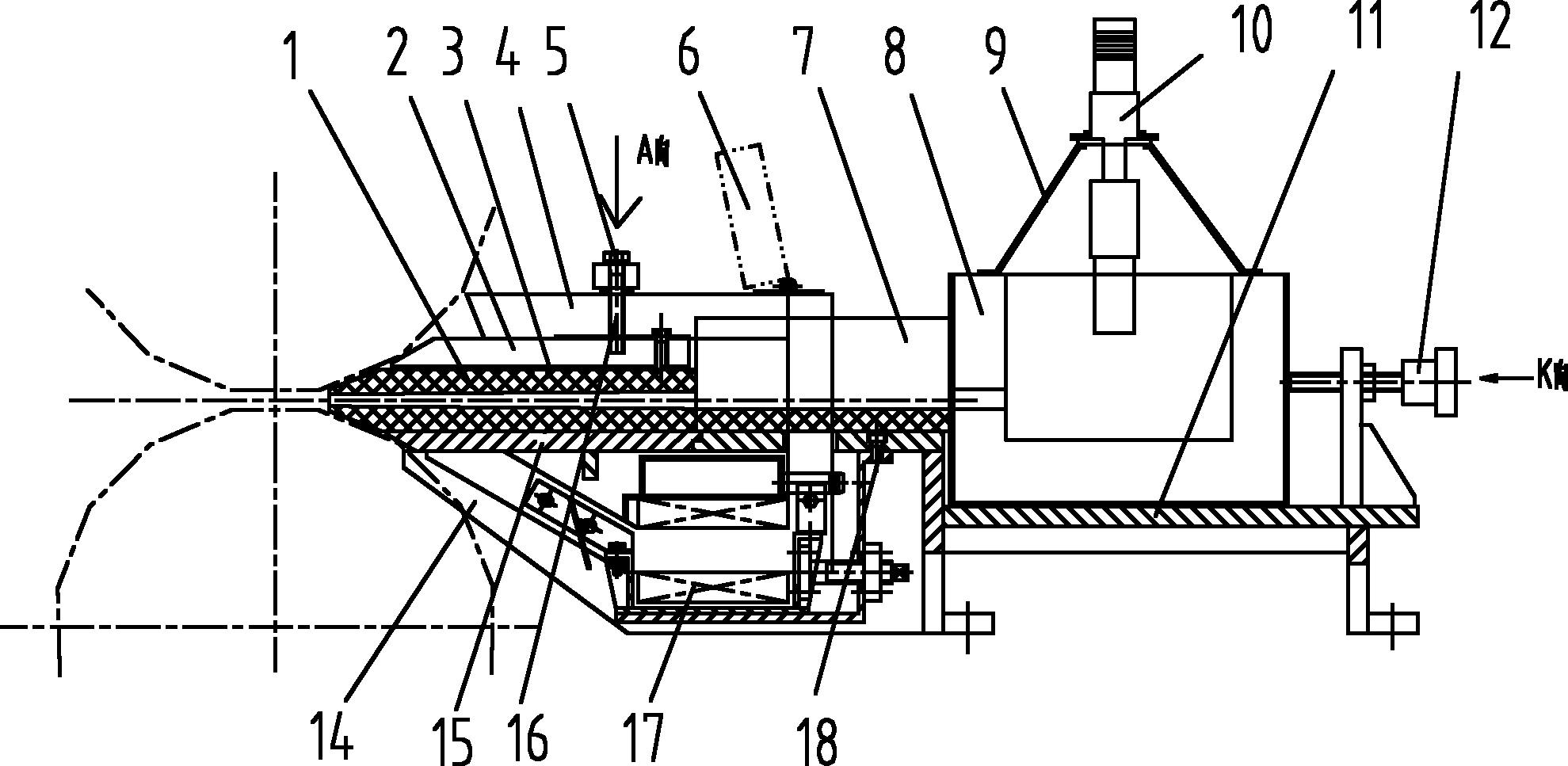

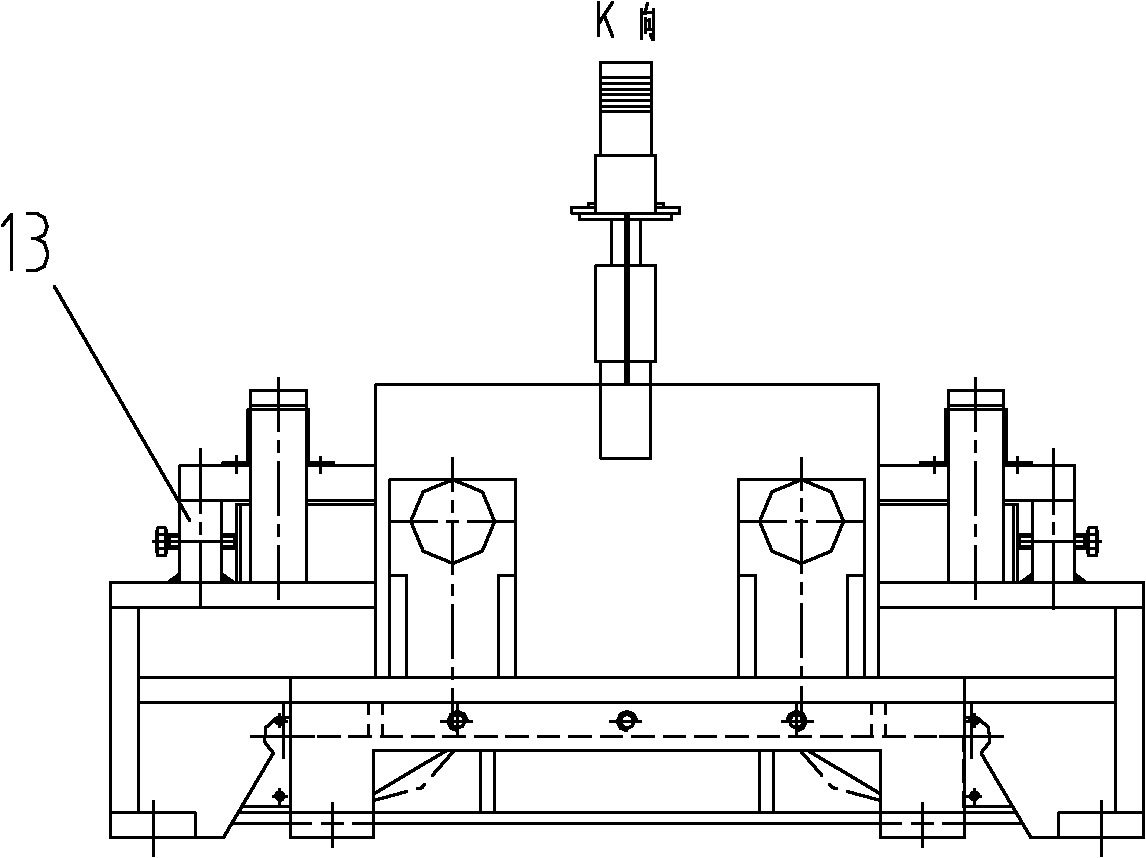

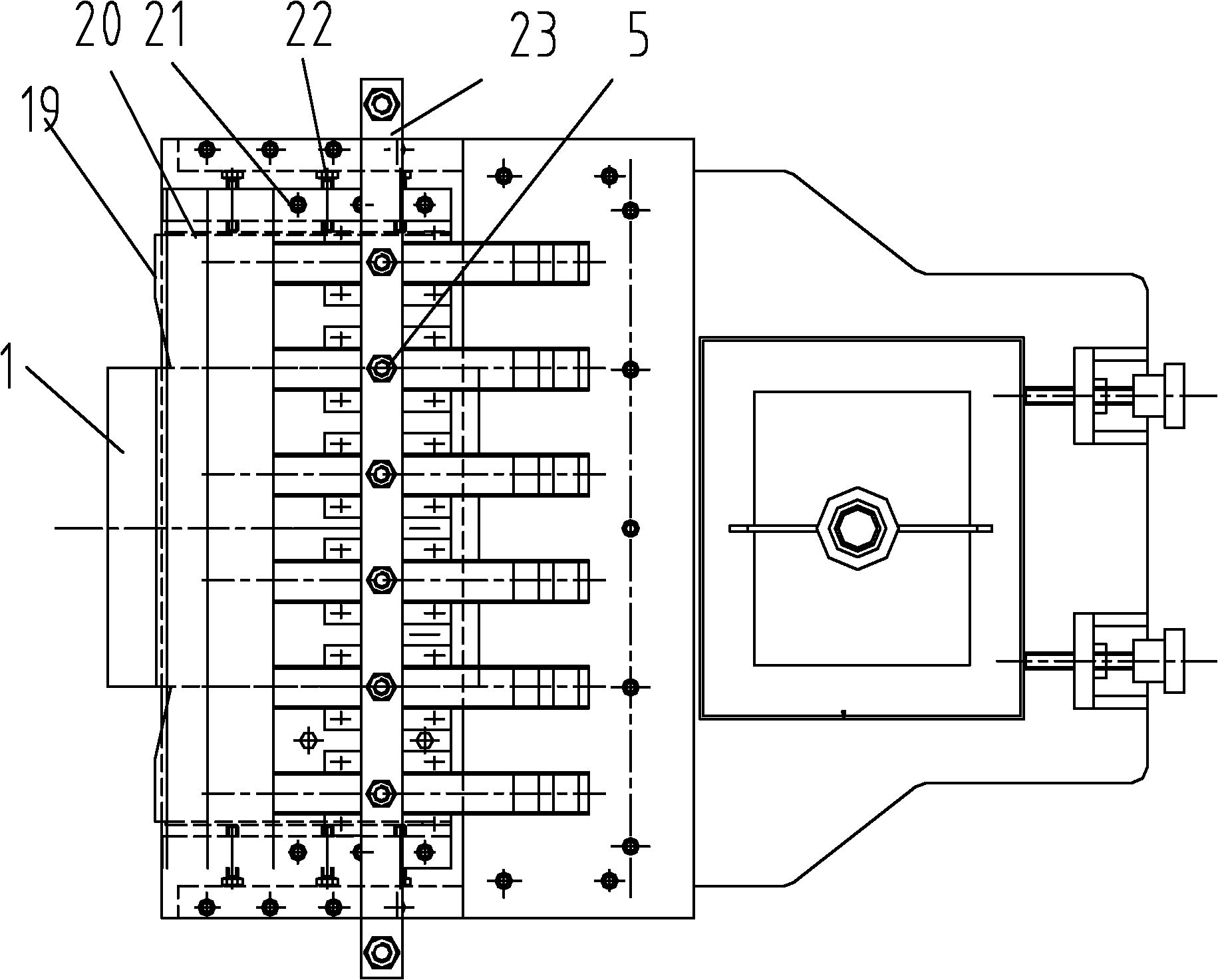

[0018] The present invention will be further described in combination with the accompanying drawings and specific embodiments.

[0019] see figure 1 , figure 2 , image 3 and Figure 4 , the nozzle support panel 15 is installed on the frame body 14 through the second bolt 18, the nozzle 1 is provided with the nozzle side ear 19, and the nozzle 1 is installed through the nozzle side ear 19, the pressure plate 20, the third bolt 21, and the fourth bolt 22 In the frame body 14, a nozzle support panel 15 is provided between the nozzle 1 and the frame body 14, the nozzle 1 communicates with the front box 8 through the aisle 7, and the front box 8 is installed on the On the frame body 14 and on the frame body 14, a front box ejector rod 12 acting on the front box 8 is provided. On the frame body 14, a magnetic field generator 17 arranged along the direction of the roll axis is fixed, and the anti-vibration rod 23 is adjusted by the adjusting bolt 24 connected and installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com