Roller type continuous cold roll forming method for Z-shaped steel sheet pile

A technology of cold-formed and steel sheet piles, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high manufacturing cost, large moment of inertia, large cross-sectional area, etc., and achieve fast exchange speed, torque saving, energy saving consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

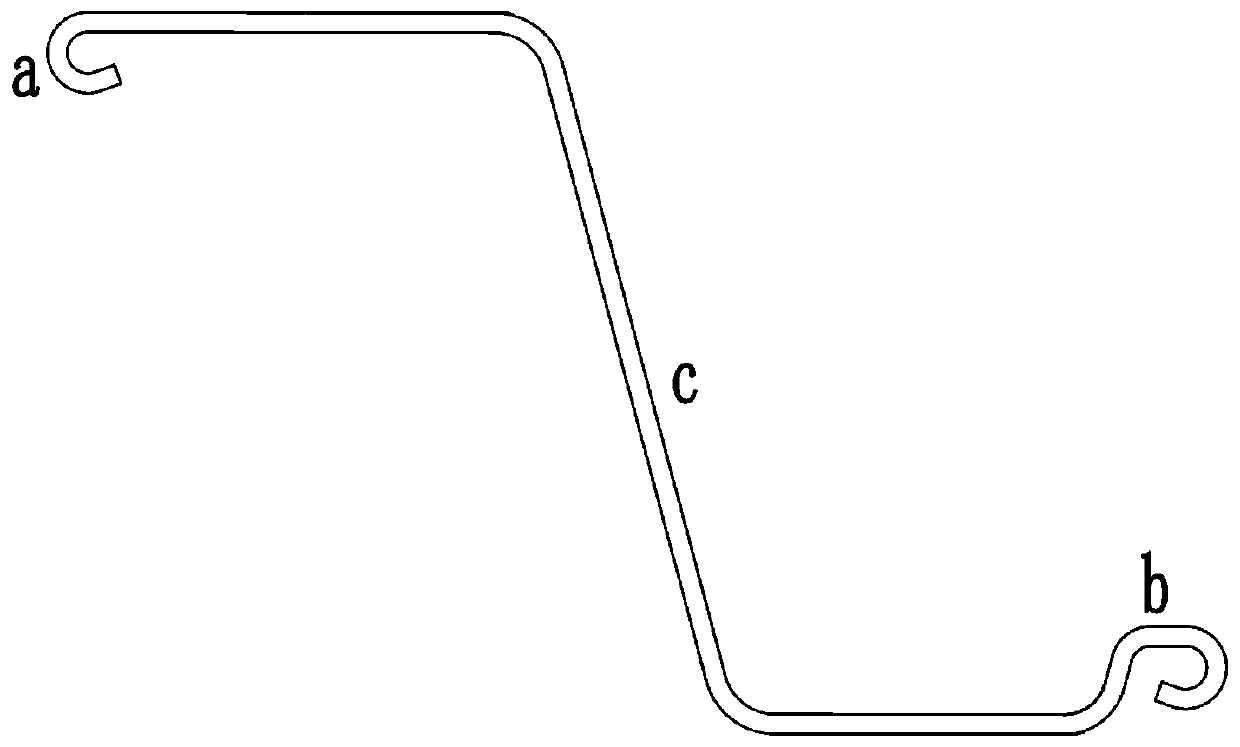

[0046] A roll-type continuous cold-bending method for Z-shaped steel sheet piles in this embodiment is characterized in that it includes feeding, uncoiling, leveling, roll-type continuous cold-bending deformation, finishing and cutting, and the specific steps are as follows:

[0047] (1) Feeding, uncoiling, and leveling: According to the specifications of steel sheet piles, steel strip coils with the same section width are selected and sent to the loading and uncoiling machine for uncoiling and leveling;

[0048] (2) After uncoiling and leveling, the strip steel coil is sent to the continuous roll cold bending unit for roll continuous cold bending deformation;

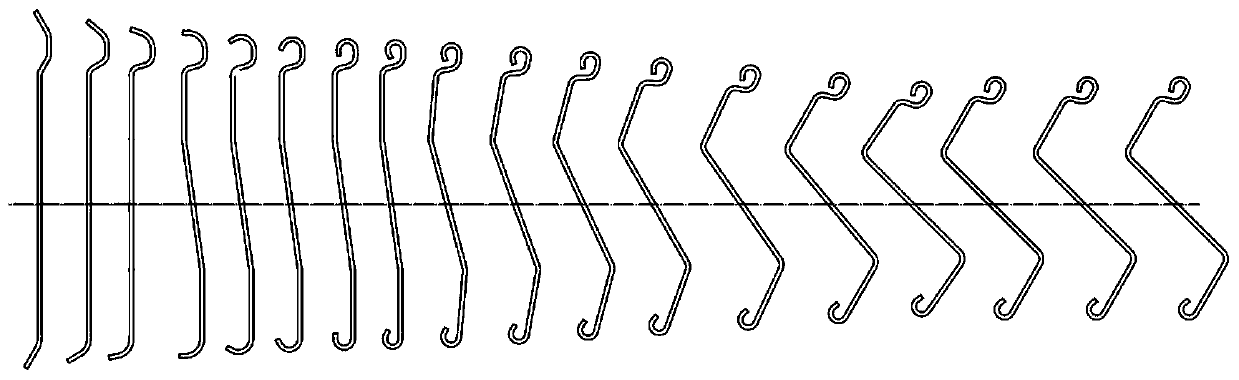

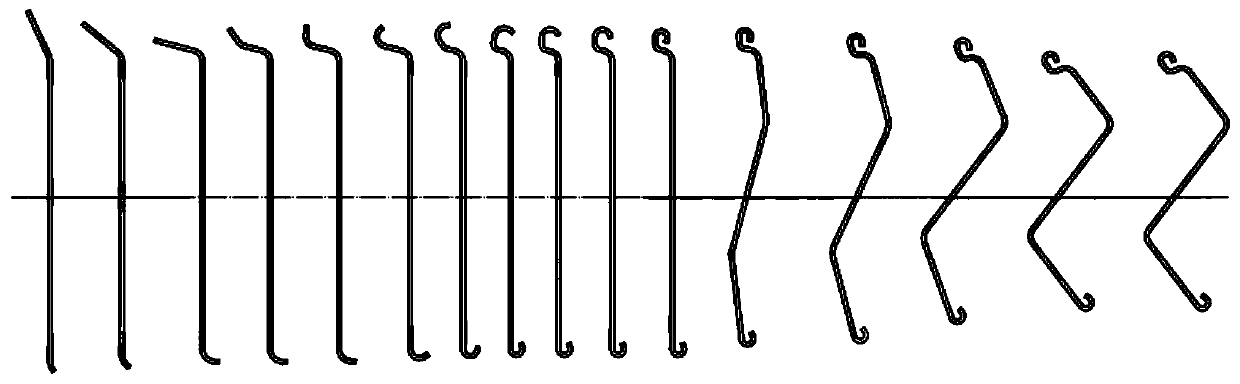

[0049] The specific process of rolling continuous cold bending deformation is as follows:

[0050] One-time cold bending: the strip steel enters the first frame and is sent into the pair of roller molds. The pass type is set to 30°, 25°, 40°, and the two sides of the strip steel are bent to be 30°, 25° to the horizonta...

Embodiment 2

[0073] A roll-type continuous cold-bending forming method for Z-shaped steel sheet piles in this embodiment, wherein the length of the strip steel is not limited, and continuous forming can be completed; the strip steel can be continued by welding, which is suitable for continuous production.

Embodiment 3

[0075] A roll-type continuous cold-bending method for Z-shaped steel sheet piles in this embodiment, wherein a high-frequency heater is installed at the first frame to preheat the edge of the strip steel, and the working frequency is 150-233 Hz;

[0076] Among them, high-frequency heaters are also installed between adjacent racks to reheat the strip edge, and the working frequency is 140-170Hz;

[0077] Preheating and reheating the edge of the strip steel by the high-frequency heater helps to reduce the difficulty of forming the strip steel, reduce the torque output of the continuous roll cold bending unit, and ensure the forming effect of the Z-shaped steel sheet pile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com