Super deep-drawing cold-rolled enamel steel produced by ASP diplex process and manufacturing method thereof

A duplex process and manufacturing method technology, applied in the field of metal material manufacturing, can solve the problem of not considering or not considering RH nitrogen circulation technology, etc., to improve product competitiveness, excellent formability and anti-scalding performance, and broaden product varieties. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

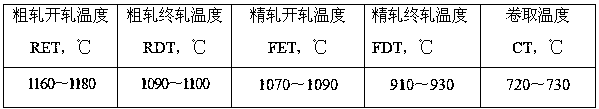

Embodiment 1

[0030] Embodiment 1 of the present invention comprises the following steps successively:

[0031] (1) Molten iron: The molten iron is not pretreated by KR, and the sulfur content of the molten iron is 0.045%;

[0032] (2) Steelmaking: The steelmaking furnace adopts a 120-ton converter, with a tapping capacity of 142.35 tons. The converter uses high-purity oxygen with a purity greater than 99.5%. The furnace maintains a positive pressure. The mass percentage of carbon during tapping is 0.0537%. The tapping temperature is 1637°C, ensuring the final slag basicity R=4~5, and doing a good job of blocking slag for tapping;

[0033] (3) LF slagging, temperature control, and S increase: The molten steel from the converter is deoxidized and slagged and temperature controlled in the LF refining furnace. The specific process: transform the highly oxidizable converter slag into FeO+MnO with a mass percentage of less than < 1.5% reducing slag can effectively prevent the transfer of oxygen...

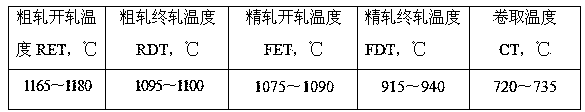

Embodiment 2

[0051] Embodiment 2 of the present invention comprises the following steps successively:

[0052] (1) Molten iron: The molten iron is not pretreated by KR, and the sulfur content of the molten iron is 0.047%;

[0053] (2) Steelmaking: The steelmaking furnace adopts a 120-ton converter with a tapping capacity of 154.06 tons. The converter uses high-purity oxygen with a purity greater than 99.5%. The furnace maintains a positive pressure. The mass percentage of carbon during tapping is 0.066%. The tapping temperature is 1651°C to ensure the final slag basicity R=4~5, and to do a good job of blocking slag and tapping;

[0054] (3) LF slagging, temperature control, and S increase: The molten steel from the converter is deoxidized and slagged and temperature controlled in the LF refining furnace. The specific process: the treatment cycle is 58 minutes, the heating time is 34 minutes, the reaching temperature is 1564 ° C, and the leaving temperature is 1660 ° C. Feed 30kg of alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com