Production device of PVA multi-product polymerization system

A system device and production device technology, applied in the chemical industry, can solve the problems of product PVA quality decline, easy pin breakage of agitator shafts, increased energy consumption, etc., so as to improve internal quality and chromaticity, improve market competitiveness, and reduce VAC content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

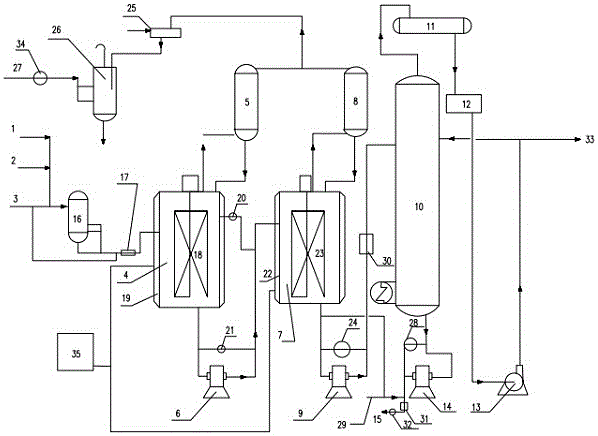

[0020] The specific embodiments of the present invention are further described with reference to the accompanying drawings, but the description scope of the present invention is not limited to this.

[0021] A PVA multi-variety polymerization system production device. The main equipment of the device includes: polymerization reactor 4, polymerization reactor resin pump 6, polymerization reactor two 7, polymerization reactor resin pump 9, polymerization tower 10, polymerization reactor pump 14, PVAC storage tank 15, polymerization preheating Reactor 16, polymerization mixer 17, polymerization agitator 18, polymerization tank jacket 19, polymerization tank jacket 22, polymerization tank agitator 23, nitrogen buffer tank 25, 26—water-sealed pressure tank, 27 —Desalinated water pipeline, 28—liquid level regulating valve of the first polymerization tower, 29—dissolved methanol, 30—the effluent mixer of the second polymerization tank, 31—the resin mixer of the polymerization one tower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com