Off-line prediction method for bell-type furnace steel roll annealing process

A prediction method and technology of annealing process, applied in the field of off-line prediction, can solve the problems of adjustment and setting of the annealing process process system, inability to adapt to changes in software, hardware and equipment performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The off-line prediction method in the bell furnace steel coil annealing process of the present invention will be described in detail below with reference to the accompanying drawings.

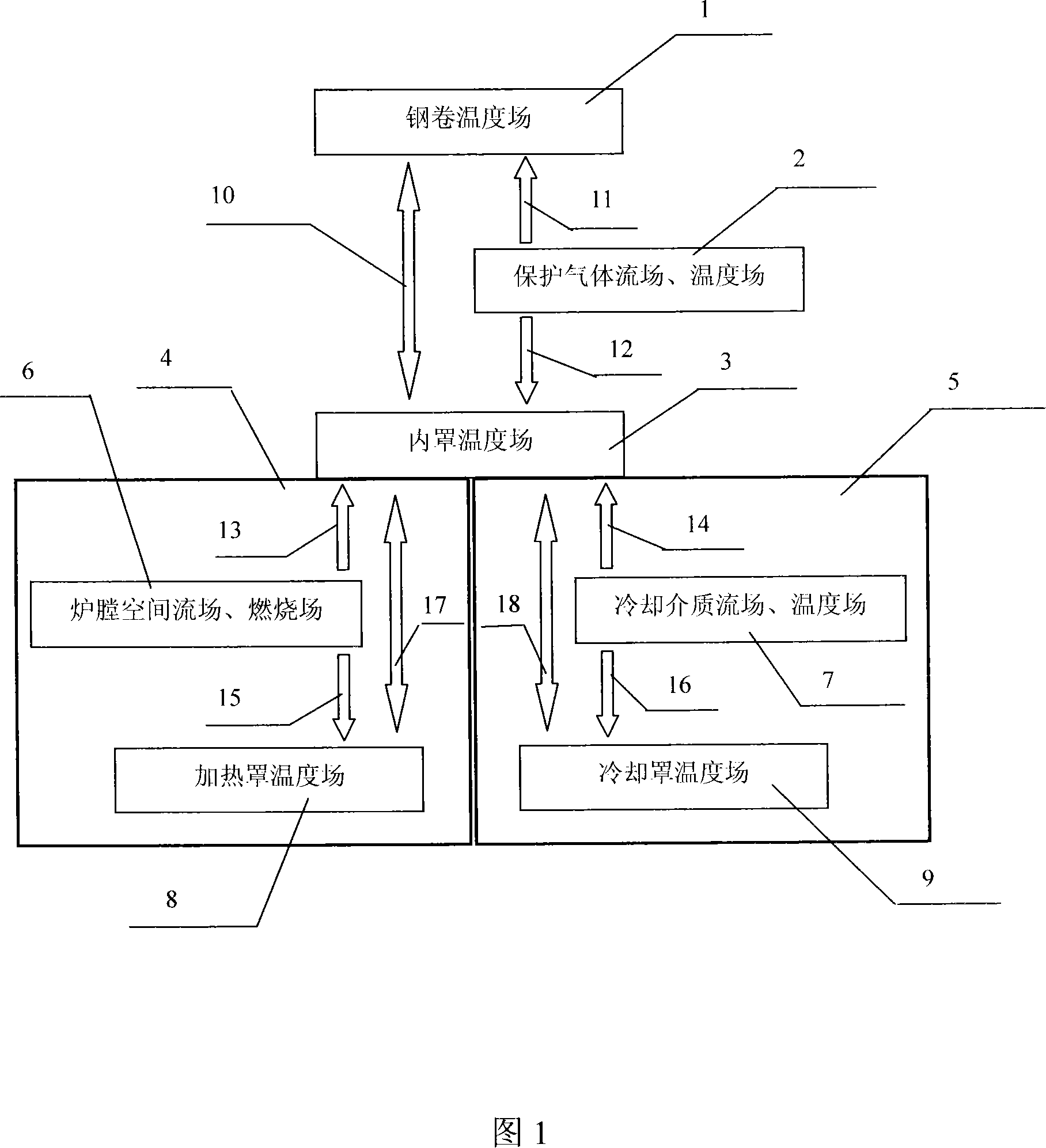

[0040] Figure 1 is a logical diagram of the temperature field coupling of the bell annealing furnace. In the figure, 1 represents the temperature field of the steel coil, 2 represents the flow field and temperature field of the shielding gas, 3 represents the temperature field of the inner cover, 4 represents the temperature coupling relationship in the heating stage, 5 represents the temperature coupling relationship in the cooling stage, and 6 represents the furnace space flow field and combustion field, 7 represents the flow field and temperature field of the cooling medium, 8 represents the temperature field of the heating mantle, and 9 represents the temperature field of the cooling mantle. Arrow 10 indicates the relationship between the coil temperature field 1 and the inner cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com