Low-silicon cold rolled precision strip steel for copper-lead bearing steel back and production method thereof

A bearing bush and steel back technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as production process difficulties, introduction of bimetallic bond strength performance parameters, increase in material costs, etc., to achieve size and uniform distribution, excellent cohesiveness, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

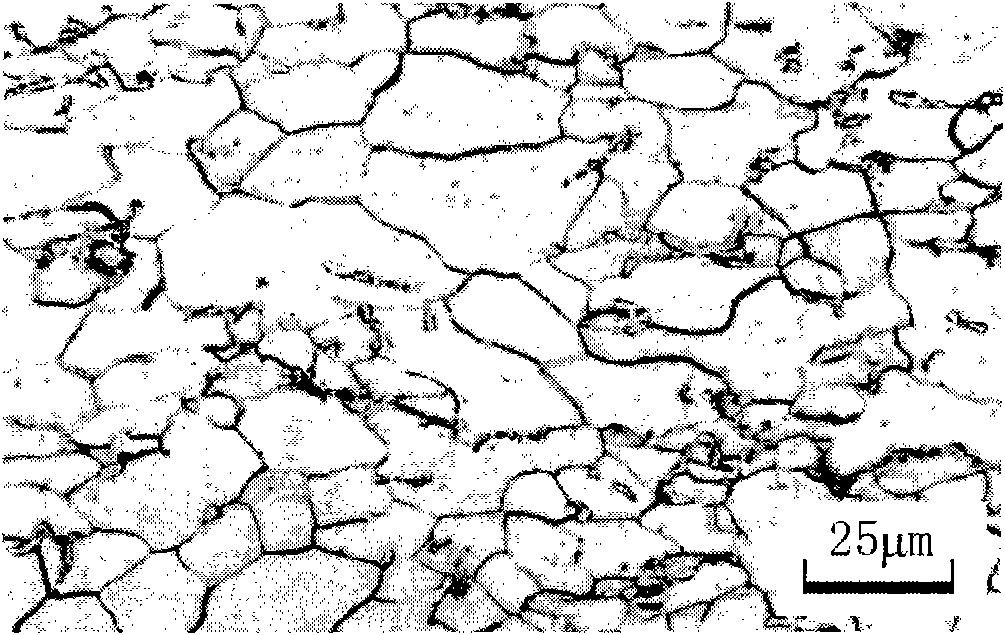

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and specific embodiment, cold-rolled precision steel strip of the present invention and production method thereof are described in further detail:

[0046] Table 1 lists the chemical composition weight percentages of low-silicon cold-rolled precision steel strips for copper-lead bearing bush steel backs in Examples 1-6 of the present invention (the balance is Fe and unavoidable impurities).

[0047] Table 1: The chemical composition weight percentage of steel strip in embodiment 1~6

[0048] Example number

[0049] The production method of the low-silicon cold-rolled precision steel strip for the copper-lead bearing bush steel back described in the above-mentioned embodiments 1 to 6 is as follows: an industrial converter with a capacity of 80 tons is blown at the top and bottom, and the deep desulfurization technology of molten iron is adopted to make the weight percentage of S in the molten iron ≤0.005, set the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com