Cover-type furnace generating steam by using waste heat

A bell-type furnace and steam technology, applied in the direction of bell-type furnaces, furnaces, furnace types, etc., can solve the problems of polluting the environment, unusable heat, and energy waste, so as to save energy, benefit the environment, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

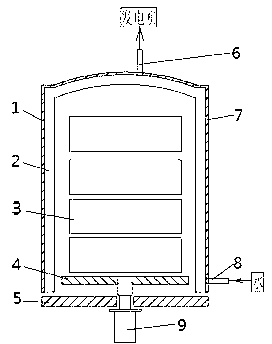

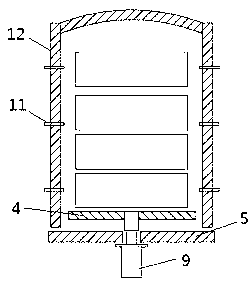

[0014] The present invention uses waste heat to generate steam bell furnace, such as figure 1 , figure 2 As shown, it includes a hearth 5, a material receiving plate 4, a heating mantle 12 and a cooling mantle 1, and the material receiving plate 4 is located on the upper part of the hearth. The lower part of the furnace platform is provided with a circulation fan device 9, and the heating cover is provided with a heating burner 11, which is connected with gas and air pipelines. The cooling cover 1 is provided with a heating jacket 2, the heating jacket is located around the inner wall and top of the cooling cover 1 cylinder, the heating jacket is provided with a water inlet 8 and a steam outlet 6, the water inlet is located at the lower part of the heating jacket, and the steam outlet is located at the heating Jacket top. The water inlet is connected with the water pipeline, and the steam outlet is connected with the steam pipe network. The outer wall and the top of the co...

Embodiment 2

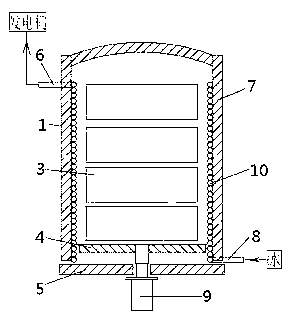

[0017] Another embodiment of the present invention is as image 3 As shown, the inner wall of the cooling cover 1 is equipped with a steam coil 10 , the lower end of the steam coil is connected to the water inlet 8 , and the upper end of the steam coil is connected to the steam outlet 6 . The water inlet is connected with the water pipeline, and the steam outlet is connected with the steam pipe network. Other structures and operation modes of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com