Method for avoiding cold rolled strip bonding and bonding-free hood-type annealing furnace

A bell-type annealing furnace and a technology for cold-rolled strip steel, applied in the field of heat treatment, can solve problems such as strip steel bonding, and achieve the effect of good effect, broad market prospect, and favorable promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

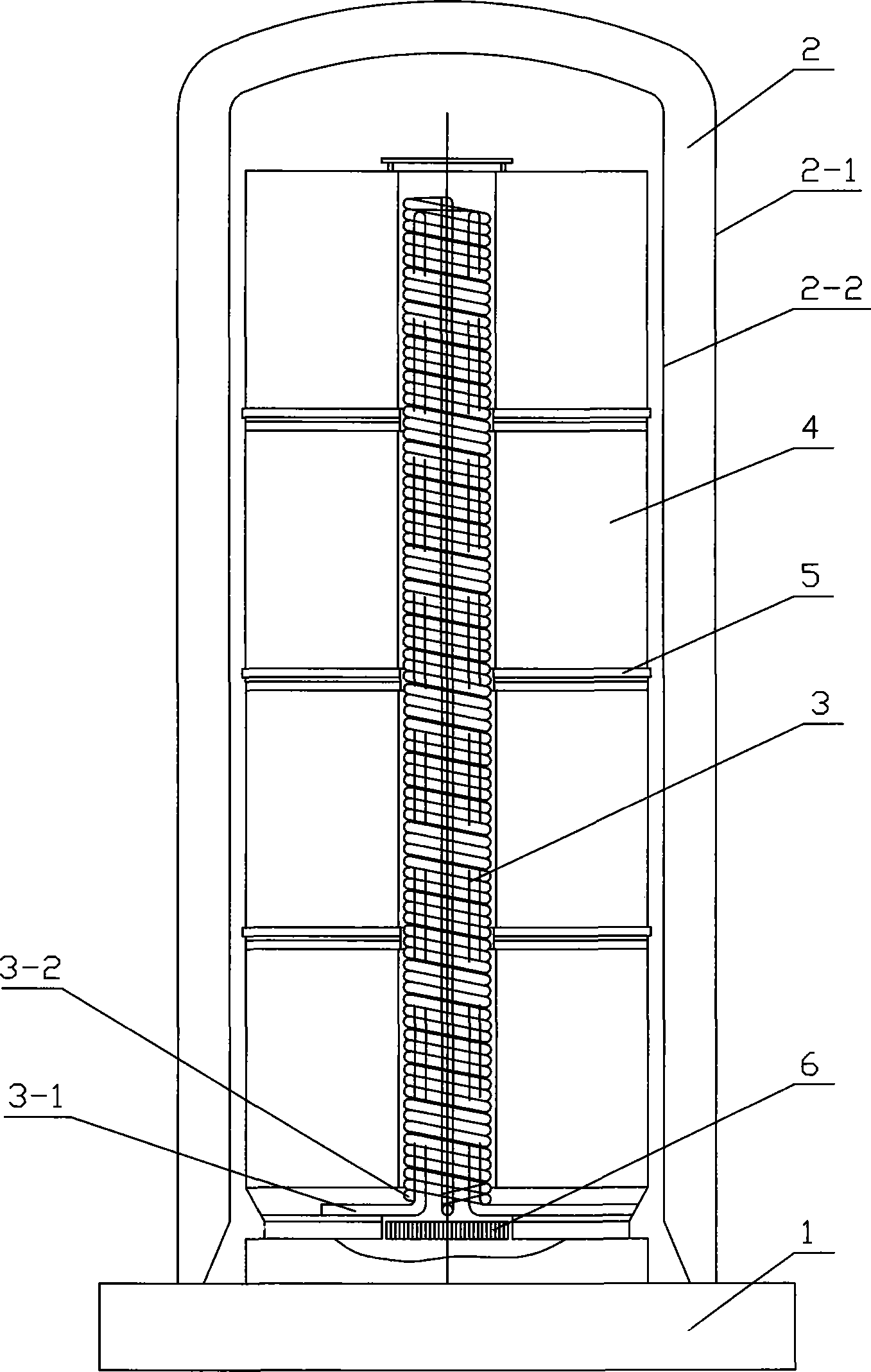

[0026] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

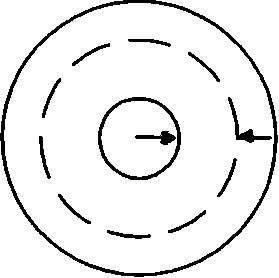

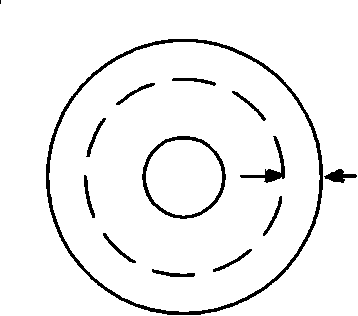

[0027] One way to avoid the bonding of cold-rolled strip steel is to control the cooling rate of the steel coil from fast to slow in order: the inner ring of the steel coil → the middle part of the steel coil (cold spot) → the outer ring of the steel coil. In this way, the steel coil is cooled from the core, and through heat conduction, the cooling rate in the middle of the steel coil is greater than that of the outer ring of the steel coil, thereby avoiding the bonding of the steel coil.

[0028] There are many ways to control the cooling rate of the middle part of the steel coil to be greater than the cooling rate of the outer ring of the steel coil. For example, at the beginning, only the inner ring of the steel coil is cooled and the outer ring is not cooled, and the cooling of the outer ring is started after the cooling of the inner ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com