Boron containing steel plate for heat treatment and manufacturing method thereof

A manufacturing method and steel plate technology, which is applied in the direction of manufacturing tools, metal rolling, temperature control, etc., can solve the problems of large tonnage of cold stamping machines, high requirements for trimming tools, and large investment, so as to achieve low production costs and high strength , complex shape effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with embodiment.

[0059] Table 2 shows the chemical composition of 8 example steels of the present invention and 3 comparative examples. Comparative examples I, J, and K are respectively US006136266A, CN200810115549.X, and EP475096.

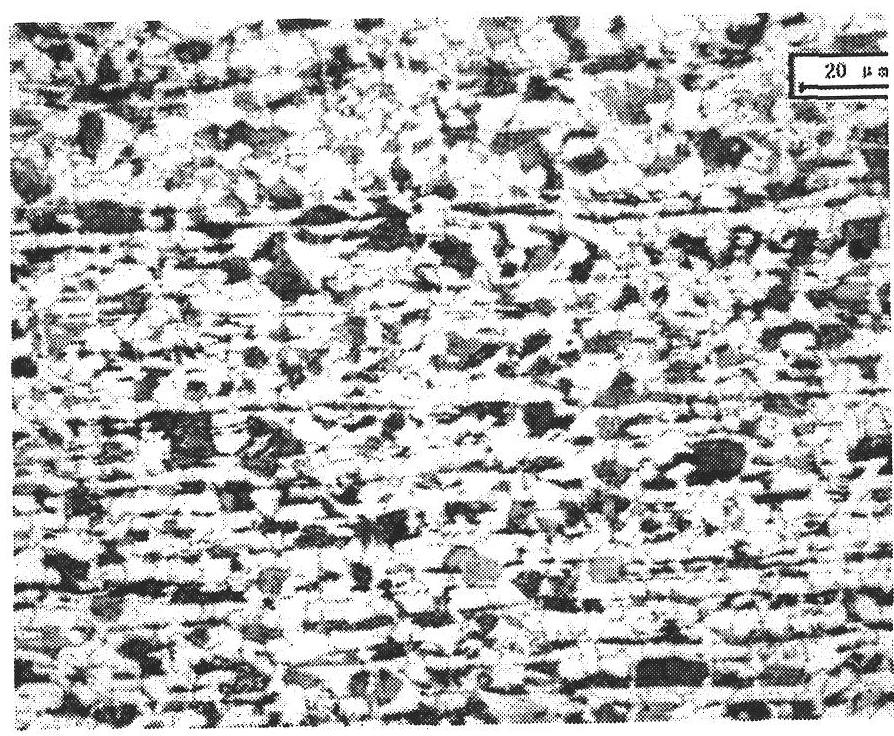

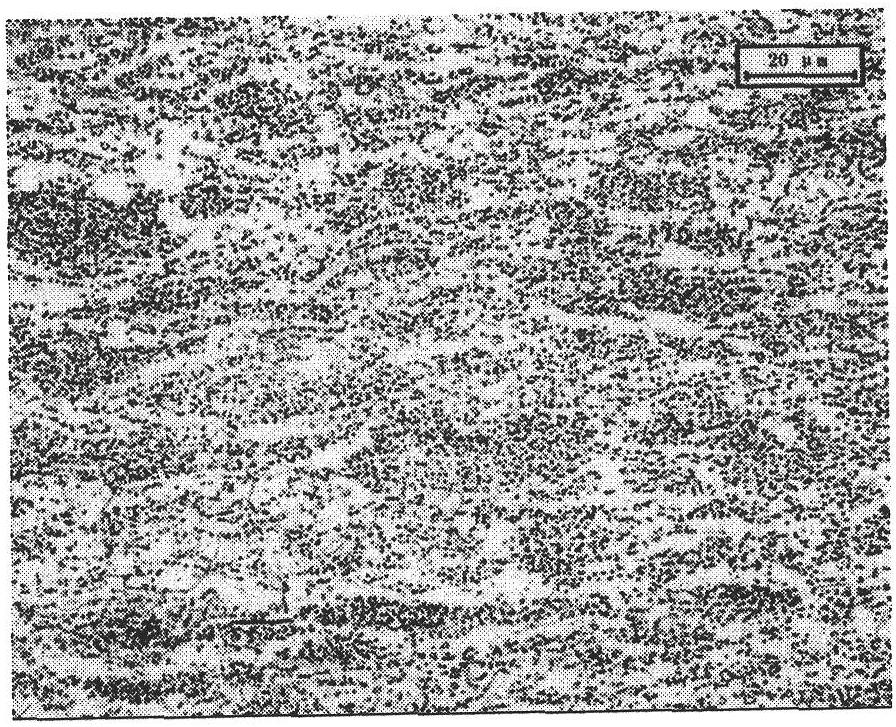

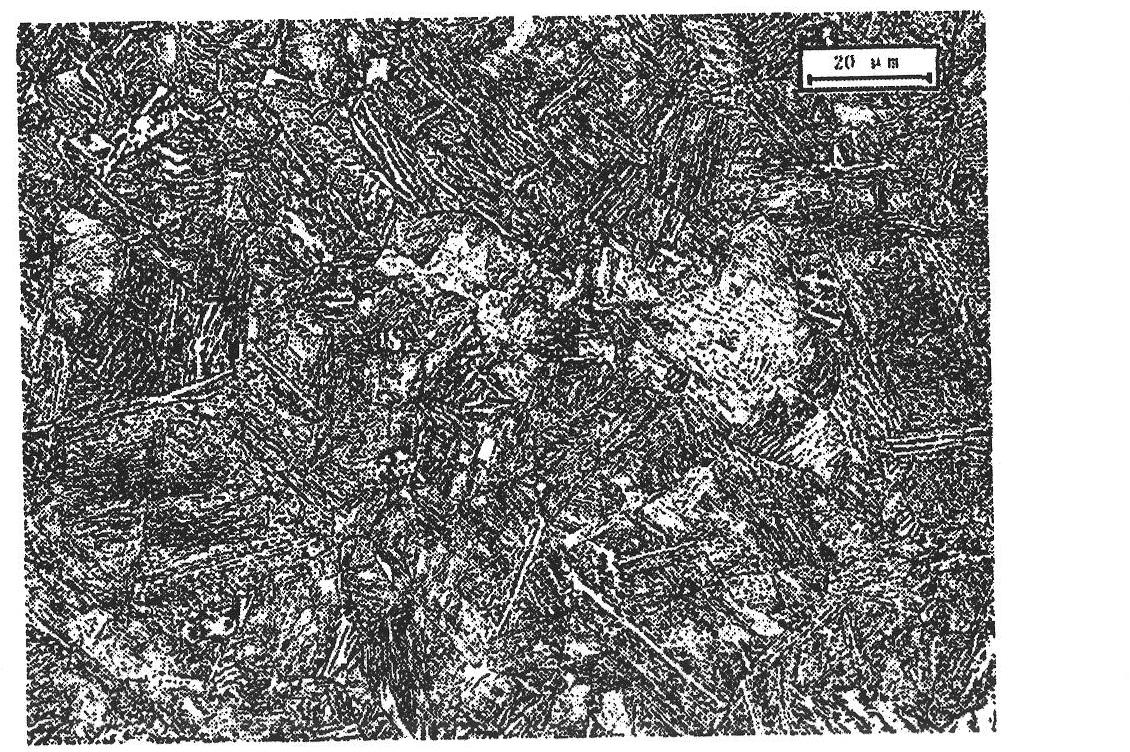

[0060] The steel of the embodiment of the present invention is smelted and hot-rolled to obtain hot-rolled products, and then cold-rolled, annealed and tempered to obtain cold-rolled annealed products. The hot-rolled, cold-rolled, annealed parameters and mechanical properties are shown in Table 3. . It can be seen from Table 3 that the steel of the present invention can obtain steel plates with a yield strength of 280-500 MPa, a tensile strength of 400-650 MPa and an elongation of 22-35% through different chemical composition ratios and appropriate processing techniques.

[0061]

[0062]

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com