High performance b4003m stainless steel manufacturing method for trucks

A stainless steel, high-performance technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of complex manufacturing process and increased manufacturing cost, so as to improve the performance level of yield strength and elongation, improve the yield, The effect of changing technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

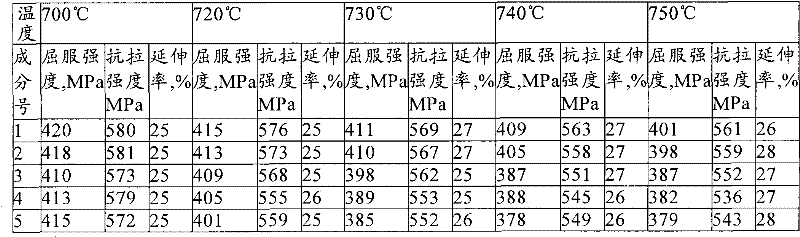

[0047] According to the chemical composition requirements of the steel grades of the present invention, steel material samples of different specifications are manufactured through smelting, continuous casting, hot rolling, annealing and pickling. Table 1 is the chemical composition of the steel of the embodiment, Table 2 is the control temperature of the process, and Table 3 is the mechanical properties of the steel of the embodiment after being kept at the temperature for 20 hours, according to the national standard GB / T 228-2002 metal material room temperature Measured by tensile test method.

[0048] The chemical composition (wt%) of the embodiment of table 1

[0049] Preface

No

C

Si

mn

P

S

Cr

Ni

N

Ti

1

0.010

1.00

2.50

0.040

0.010

11.0

0.60

0.020

0.10

2

0.011

0.80

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com