Control method of rolling deflection of hot-rolled strip steel

A control method and technology for hot-rolled strip steel, applied in the direction of rolling force/roll gap control, etc., can solve the problems of strip steel finishing rolling and rolling deviation, reduce rolling deviation scrap, improve hot-rolling rolling Stability and shape quality of strip products, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

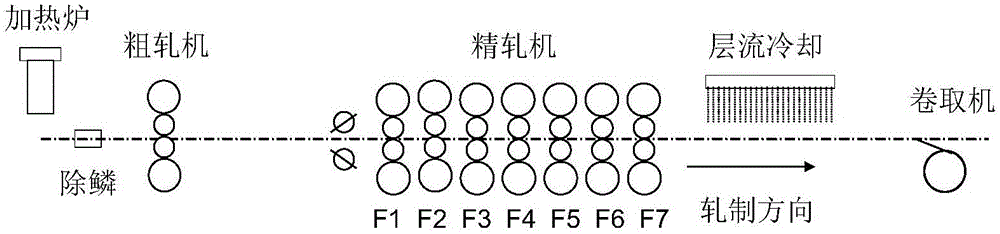

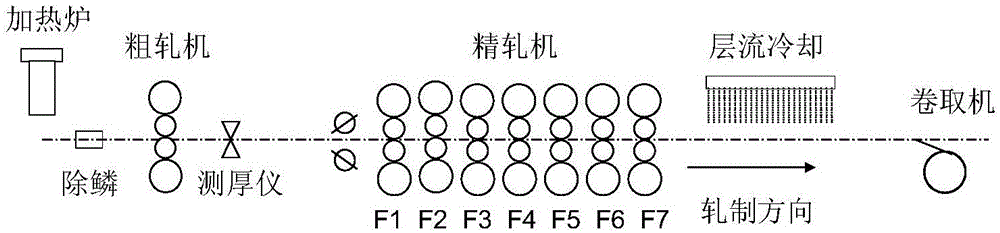

[0032] Such as image 3 As shown, conventional hot rolling lines generally need to go through slab heating, high-pressure water descaling, rough rolling, head and tail cutting, finish rolling, laminar cooling, and coiling. Compared with conventional hot rolling lines, this application has A thickness gauge is added at , which is used to detect the transverse thickness distribution of the intermediate billet, so as to calculate the wedge shape of the intermediate billet. In this embodiment, the strip deviation control method is a method based on the wedge measurement of the intermediate billet and the wedge compensation of the roll gap of the rolling mill. According to the measurement data of the transverse thickness of the rough rolling intermediate billet, the wedge compensation amount of the finishing roll gap is calculated, and Reasonably set the reduction on both sides of each stand of the finish rolling mill to reduce rolling deviation of scrap steel and improve the stabi...

Embodiment 1

[0050] For the production process of a hot-rolled product, the width of the rough rolling intermediate billet is 1250.0mm, the thickness is 35.0mm, the thickness of the operation side and the transmission side are 35.02mm and 34.22mm respectively, and the exit thickness of each stand of the finish rolling mill is shown in Table 1.

[0051] Table 1 Finish rolling mill exit thickness of each stand

[0052]

[0053] Calculate the wedge shape of the intermediate billet as:

[0054] W e =h w -h d =35.02-34.22=0.80(mm)

[0055] and a proportional wedge:

[0056]

[0057] Table 2 shows the calculated roll gap wedge compensation for each stand of the finish rolling mill.

[0058] Table 2 Wedge compensation amount of roll gap for each stand of finishing rolling mill

[0059] frame F1 F2 F3 F4 F5 F6 F7 Compensation amount / mm 0.54 0.38 0.27 0.20 0.15 0.12 0.10

Embodiment 2

[0061] For the production process of a hot-rolled product, the width of the rough rolling intermediate billet is 1650.0mm, the thickness is 40.0mm, the thickness of the operation side and the transmission side are 41.35mm and 39.94mm respectively, and the exit thickness of each stand of the finish rolling mill is shown in Table 3.

[0062] Table 3 Finish rolling mill exit thickness of each stand

[0063]

[0064] According to the calculation formula of this application, the wedge shape of the intermediate blank can be calculated:

[0065] W e =h w -h d =41.35-39.94=1.41(mm)

[0066] and a proportional wedge:

[0067]

[0068] Thus, the wedge compensation amount of the roll gap of each rolling mill is calculated as shown in Table 4.

[0069] Table 4 Roll gap wedge compensation amount of each rolling mill

[0070] frame F1 F2 F3 F4 F5 F6 F7 Compensation amount / mm 0.93 0.64 0.46 0.35 0.28 0.24 0.21

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com