Finish rolling strip steel load distribution setting method

A setting method and load distribution technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of large fluctuation of stand thickness distribution and large fluctuation of rolling force ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

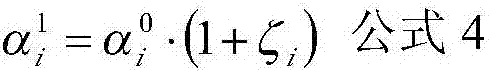

[0128] Example 1, the information of a certain steel strip is as follows: the thickness of the intermediate billet is 40.377 mm, the thickness of the final rolling is 1.8 mm, the width of the steel strip is 1229.1 mm, and the number of rolling passes of the finishing rolling is n=7. Steel grade information: The steel grade is 11002, the thickness grade is 5, and the width grade is 3. The corresponding layer grade data is as follows:

[0129] Table 1 Distribution coefficient of reduction rate

[0130]

[0131] Table 2 Rolling Force Distribution Coefficient

[0132] Steel category

Thickness grade

α1

α2

α3

α4

Alpha 5

α6

α7

11002

5

1

0.95

0.88

0.78

0.55

0.45

0.36

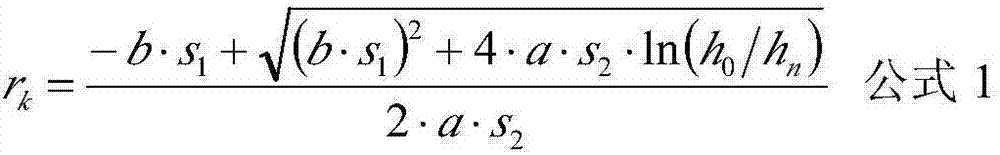

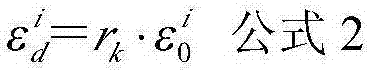

[0133] In the above step S1, the thickness distribution of each stand of the finish rolling is calculated according to the reduction distribution coefficient table and the distribution mode according to the reduction,

[0134] In order to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com