Method for setting load distribution of finish rolling band steel

A load distribution and setting method technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of low adjustment efficiency, insurmountability, and poor coordination between stands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

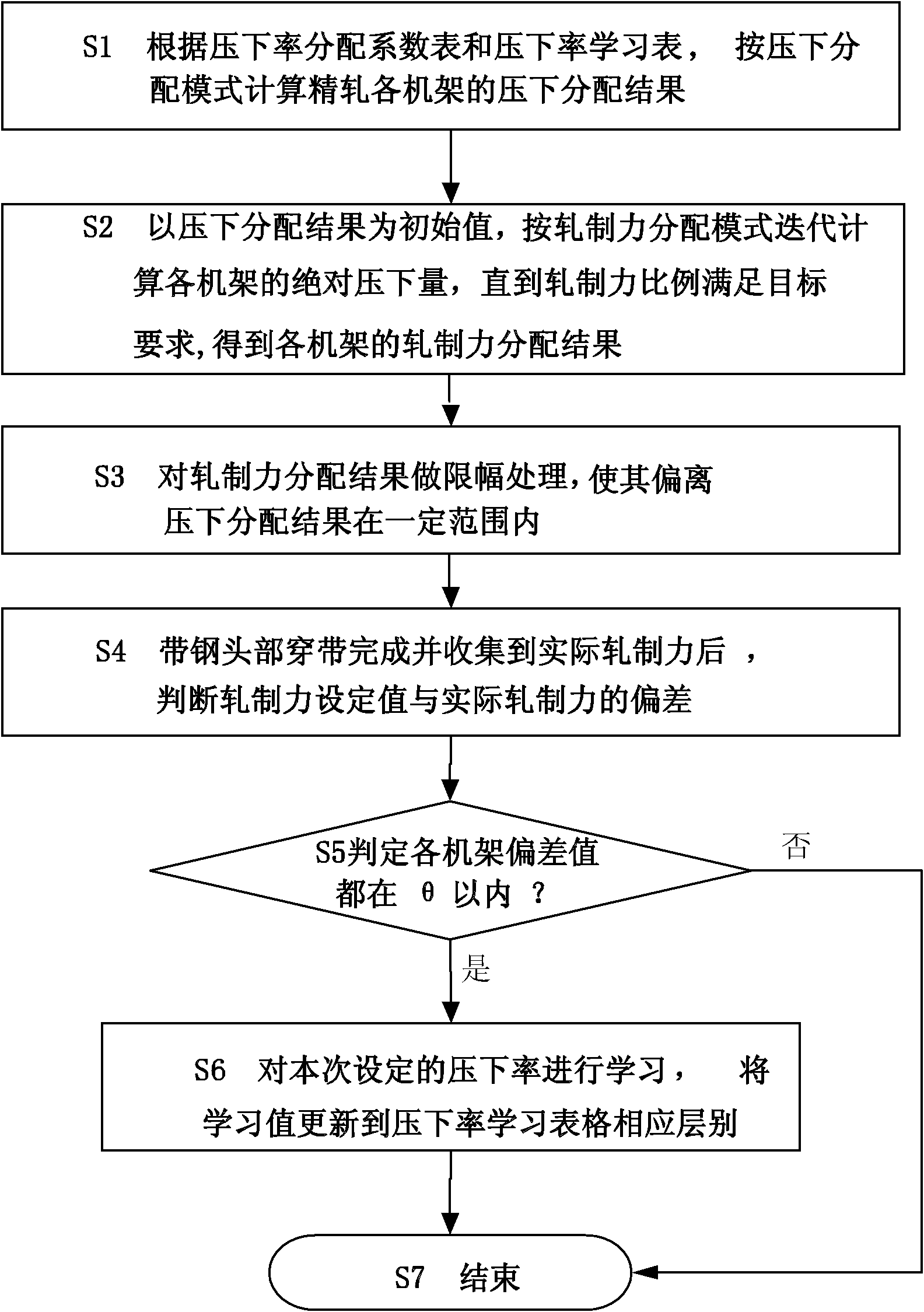

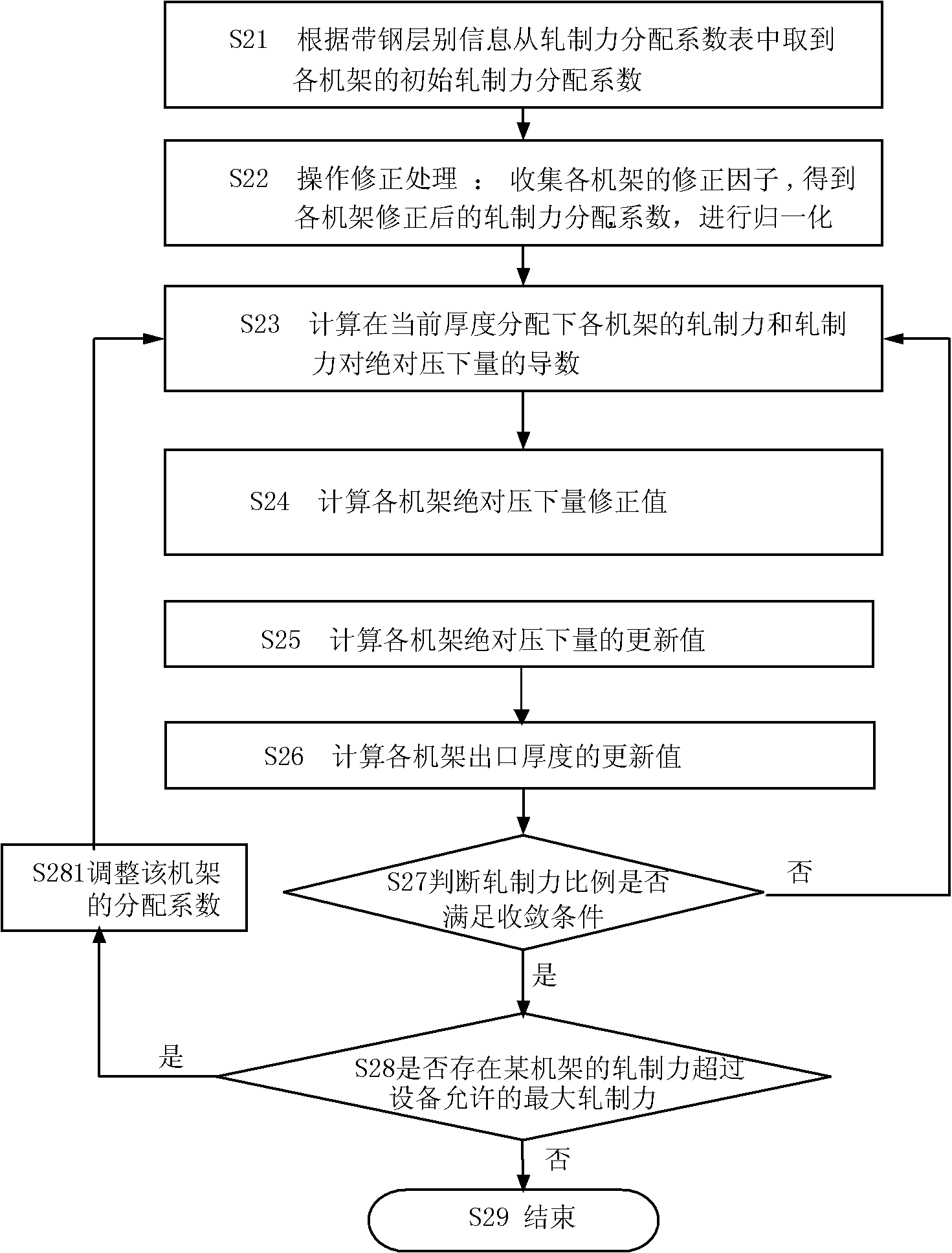

Method used

Image

Examples

Embodiment 1

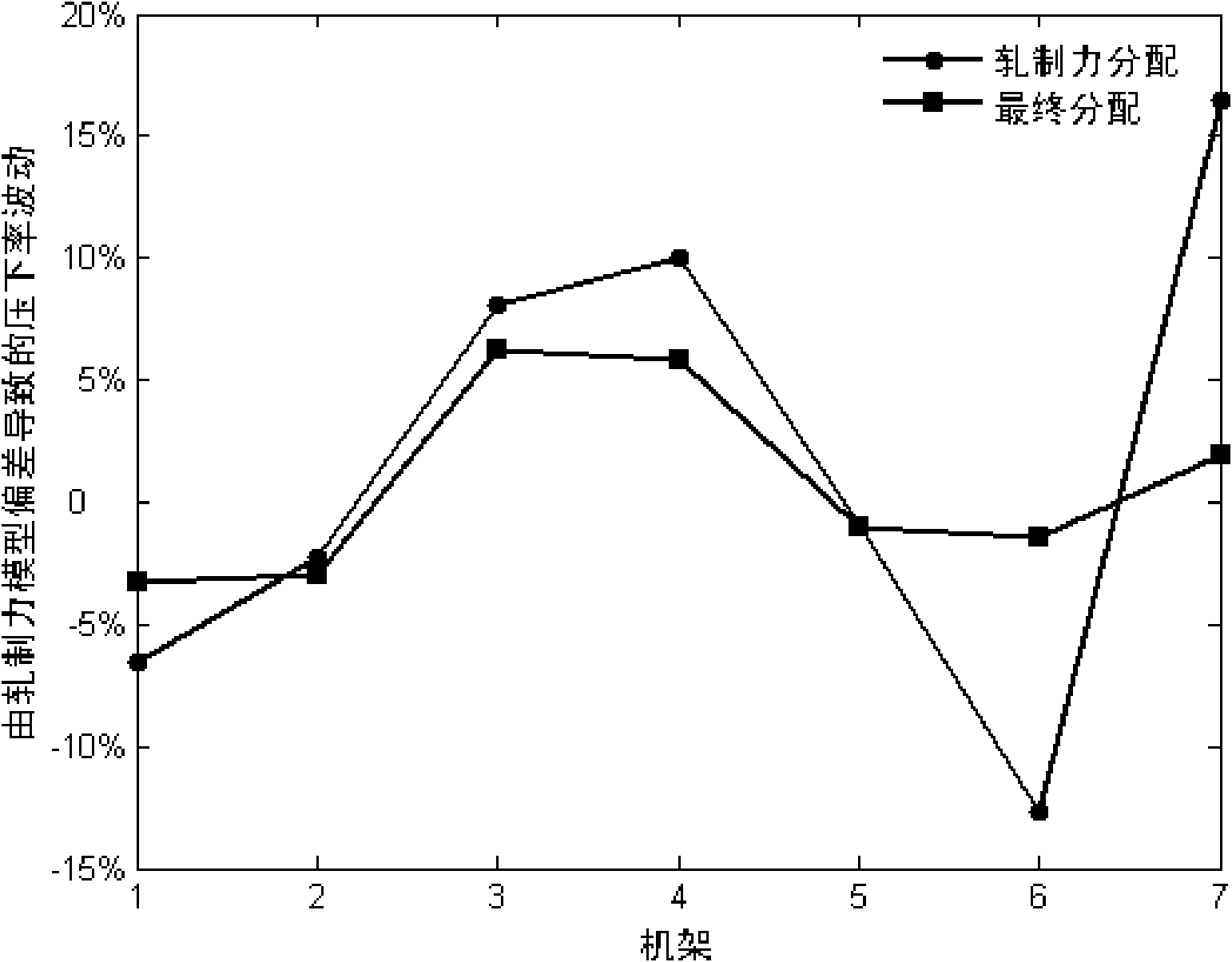

[0180] Focus on explaining the entire calculation process. The final result is the distribution of rolling force after reduction distribution and limiting, which overcomes the disadvantages of large fluctuations in stand reduction rate when rolling force distribution is used alone (in this case, when the error of the rolling force model is large and the process conditions change greatly occurs, the rolling force distribution needs to adjust the reduction rate to meet the requirements of the rolling force ratio of each stand, so the reduction rate fluctuates greatly; when the reduction distribution is used, the reduction rate of each stand remains almost unchanged), It is beneficial to improve the setting accuracy and rolling stability of the rolling schedule of the finished strip steel.

[0181] The information of a certain strip is as follows: the thickness of the intermediate billet is 40.69mm, the thickness of the final rolling is 2.0mm, the width of the strip is 1233.6mm, ...

Embodiment 2

[0225] Rack equipment limit testing.

[0226] Strip steel information: the thickness of the intermediate billet is 42.308mm, the thickness of the final rolling is 4.597mm, and the number of passes is n=7. The rolling force distribution coefficient required in step S2 is as follows in Table 15:

[0227] SGF

THICK

α1

α2

α3

α4

α5

α6

α7

11002

16

1

0.98

0.88

0.78

0.62

0.45

0.36

[0228] Rolling force overrun inspection

[0229] For the convenience of comparison, the load distribution in two cases is calculated separately: one is that there is no limit to the maximum rolling force of F2; the other is that the maximum rolling force of F2 is limited, assuming The calculation results are compared in Table 16 below.

[0230]

F1

F2

F3

F4

F5

F6

F7

α i

1

0.98

0.88

0.78

0.62

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com