Roll shape configuration method for whole-set precision rolling working roll

A configuration method and technology of work rolls, which are applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problem that the roll matching method cannot meet the requirements of large crown at the end of the cold-rolled material, so as to improve rolling stability and expand The effect of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

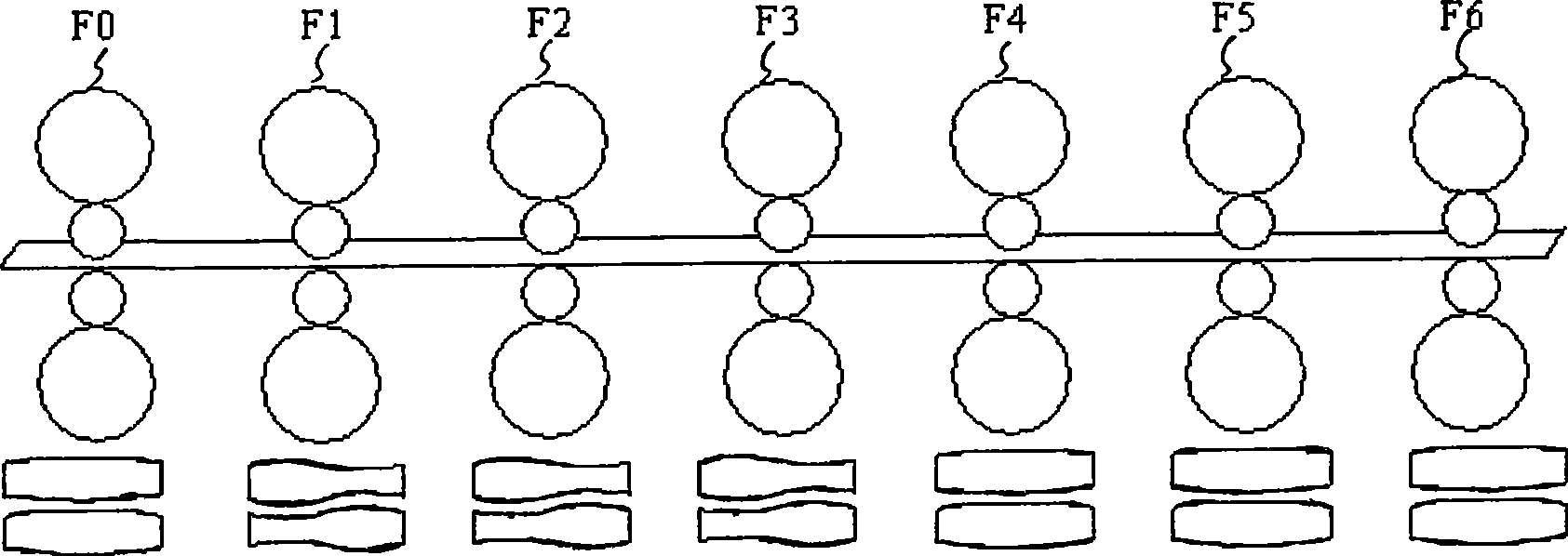

[0024] refer to Figure 4 , a complete set of finish rolling work roll configuration method, the finish rolling work rolls are configured as 7 stands, the first finish rolling stand F0 uses flat rolls, and the finish rolling work rolls F1 ~ F3 work rolls are input on the CNC grinding machine (Pomini, Italy) The CVC__1 type work roll can be ground by the table provided by SMS through the calculation of the CVC roll profile curve, and the F6 work roll adopts the CVC__2 type, which is ground by the Italian Pomini CNC grinding machine by inputting the coefficients of the equation.

[0025] F6 work roll roll type cubic curve equation is: R u0 (x)=A 0 +A 1 x+A 2 x 2 +A 3 x 3

[0026] R in the above formula 0 (x) is the radius function of CV'C roller;

[0027] The value range of A0 is 320~420;

[0028] The value range of A1 is (6.0~8.0)E—4;

[0029] The value range of A2 is (1.0~3.0)E—6;

[0030] The value range of A3 is (4.0~6.0)E—10

[0031] F0 work rolls can be ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com