Hot rolled strip steel load distribution method giving consideration to rolling energy consumption and good strip shape

A load distribution, hot-rolled strip technology, applied in the field of control, can solve problems such as long calculation time, unfavorable shape control accuracy and rolling stability, difficulty in meeting real-time requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

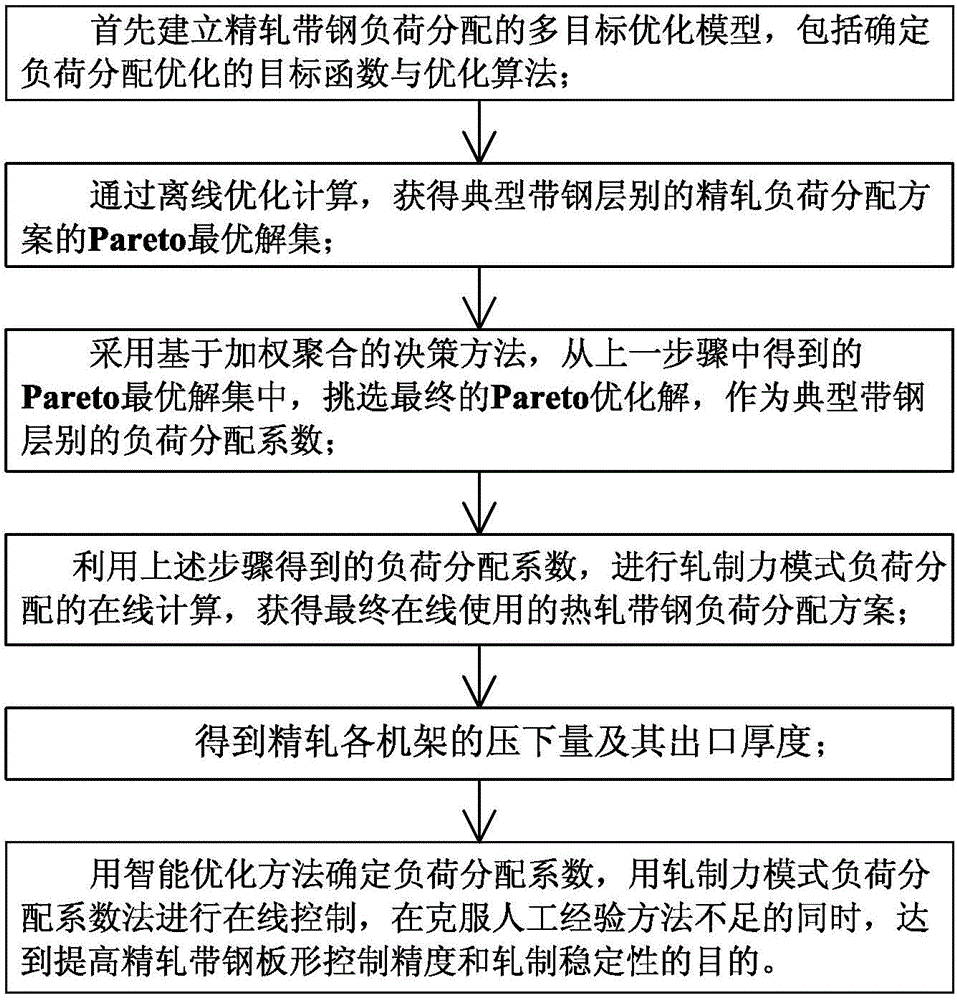

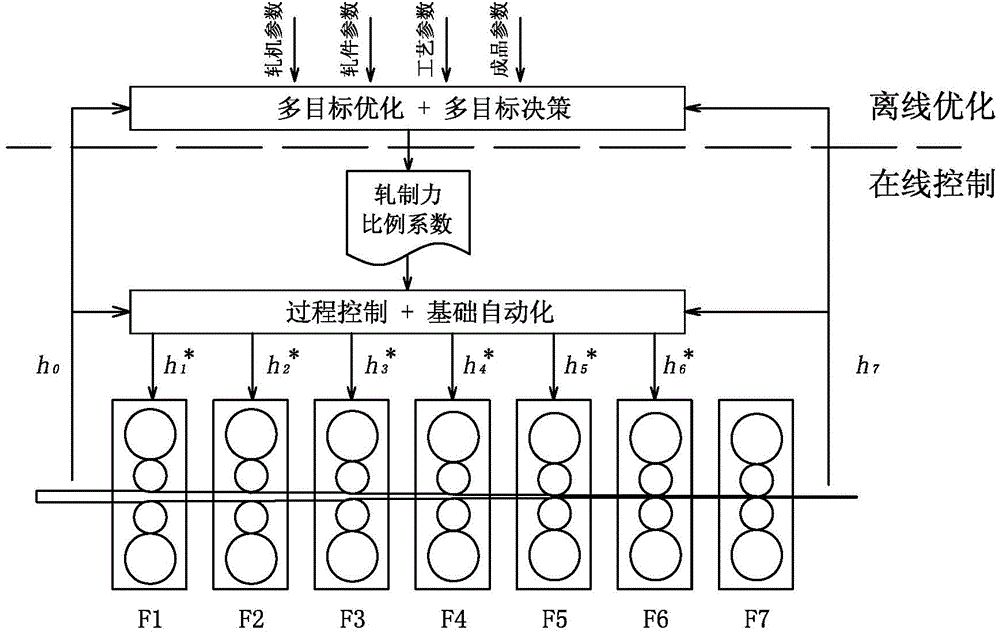

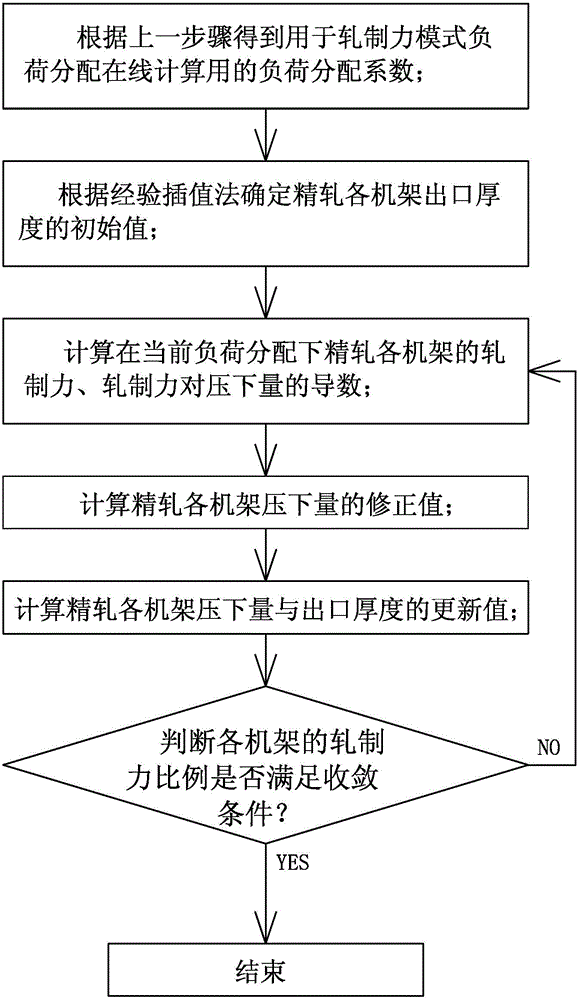

Method used

Image

Examples

Embodiment

[0173] Select a typical carbon steel as an example, the steel type is Q235B, the strip width is 1244mm, and the intermediate billet thickness h 0 is 42.6mm, the final rolling target thickness h n is 3.38mm, the target crown is 40um, and the number n of finishing stands is 7.

[0174] Selection of model parameters in formula (3): a=40, b=1.86.

[0175] The multi-objective optimization model shown in formula (5) is carried out on the carbon steel, and the non-dominated sorting genetic algorithm (NSGA-Ⅱ) of the elitist strategy is used to solve it.

[0176] In the NSGA-II algorithm, the number of populations is 100, and the maximum number of iterations is 40. After 40 iterative calculations, the Pareto optimal solution set of the strip finish rolling load distribution can be obtained, Figure 4 is the change of the objective function with the number of iterations.

[0177] It can be seen from the figure that after 20 iterations, the two objective functions begin to stabilize....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com