A load distribution method for strip hot continuous rolling

A technology of load distribution and hot continuous rolling, applied in the field of control, can solve the problems of large deviation of the initial value of load distribution, cumbersome calculation process of rolling force mode, long calculation time, etc., achieve good flatness, improve setting accuracy and Rolling stability, the effect of overcoming uneven distribution of reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

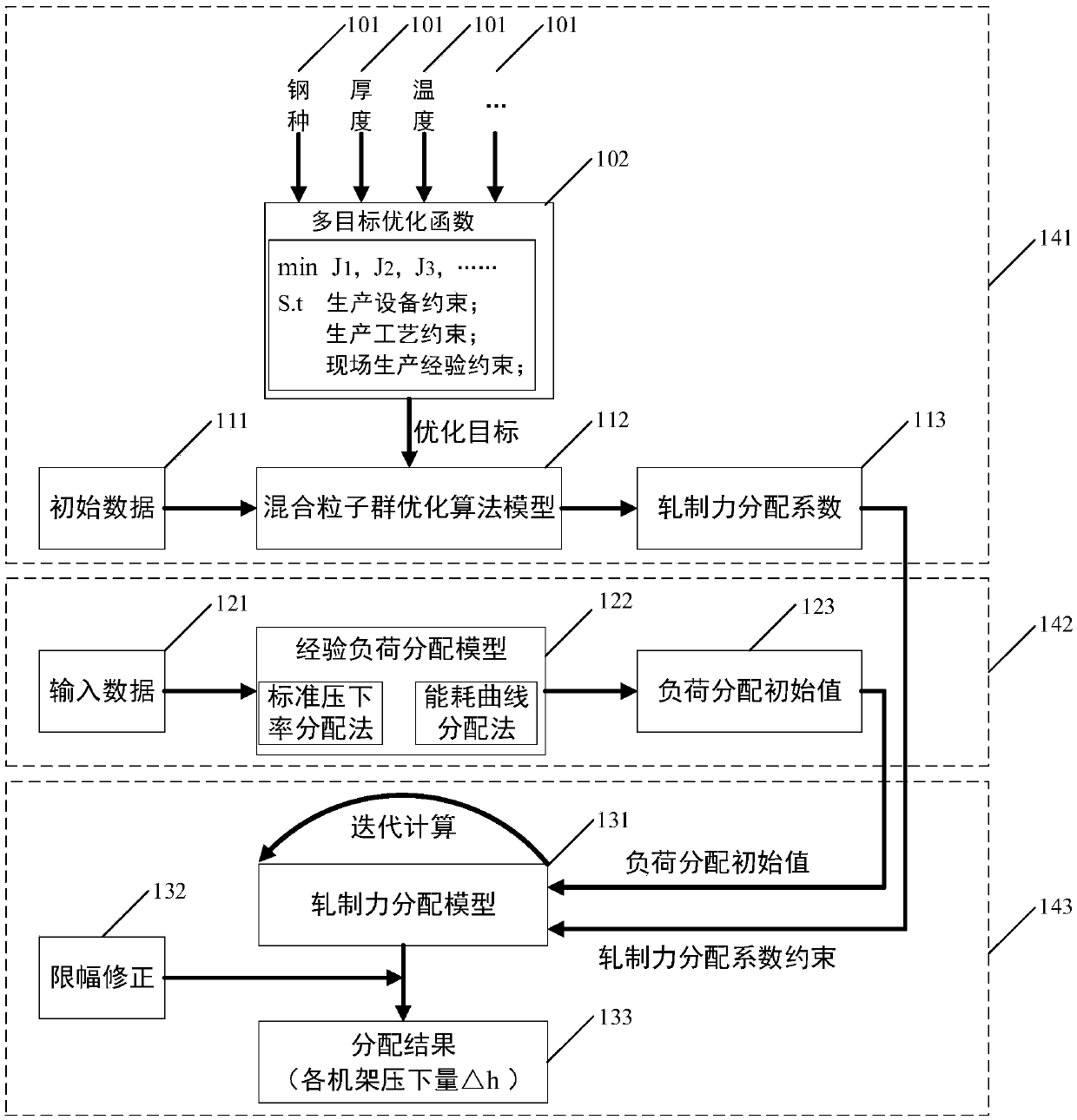

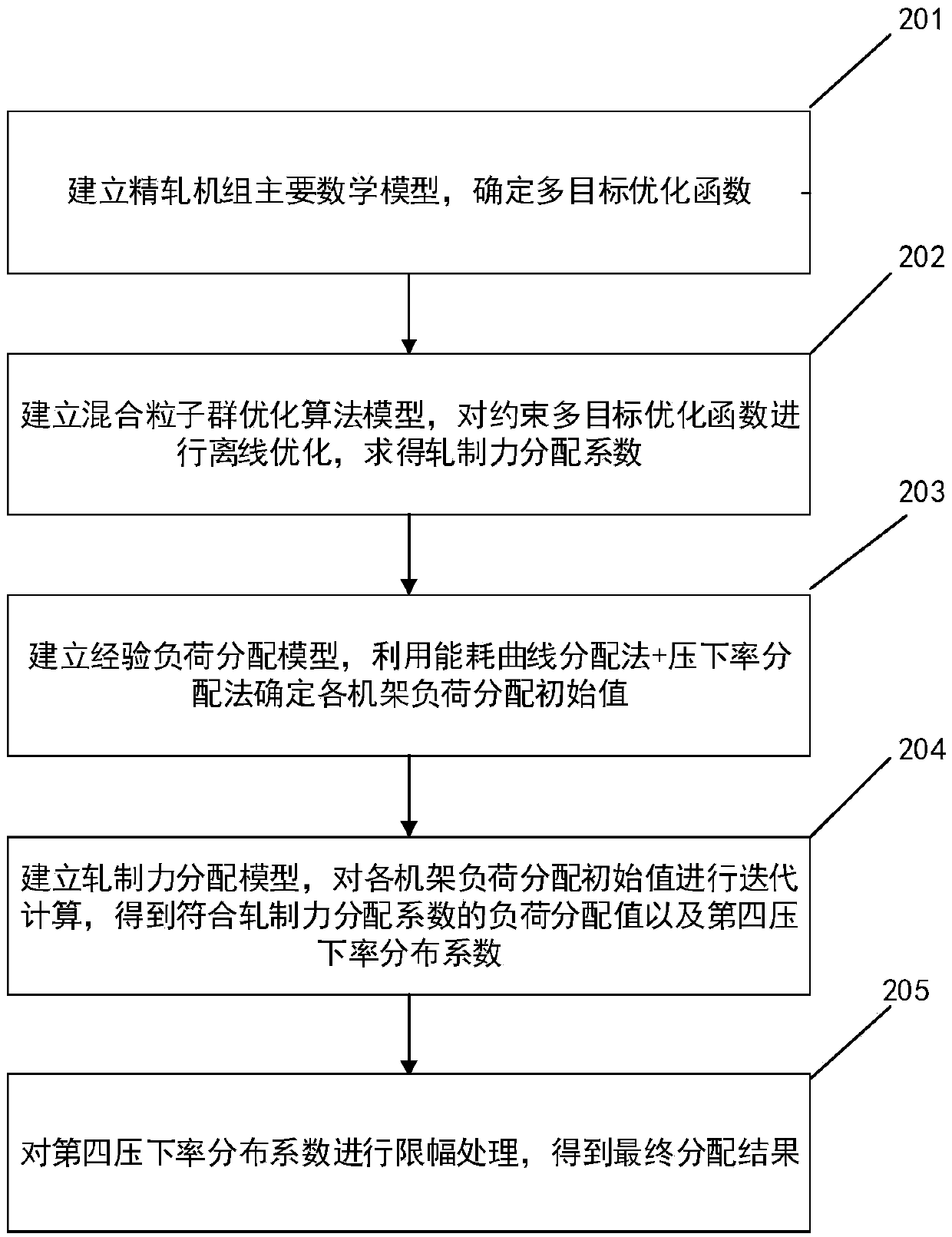

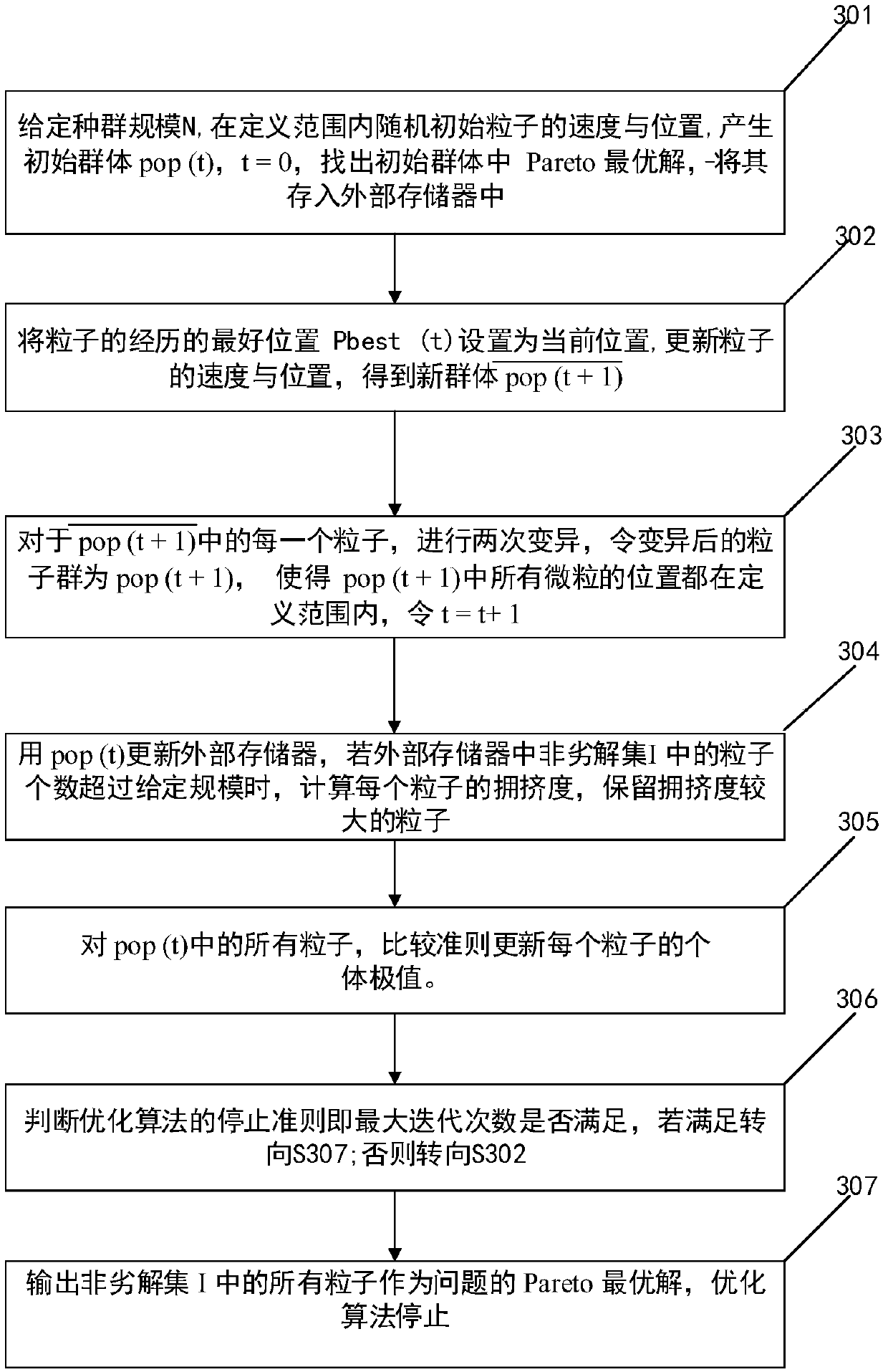

[0024] The present invention firstly provides a load distribution method for strip hot rolling, which can take into account both rolling energy consumption and good shape. The present invention combines "offline optimization + offline optimization + online control" and uses the hybrid particle swarm optimization method for offline optimization Obtain the rolling force distribution coefficient of the typical strip layer; use the empirical load distribution model to optimize the initial reduction rate offline to obtain a more reliable initial load distribution value; use the iterative calculation of the rolling force distribution model to realize online calculation and real-time On-line control can not only meet the time req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com