Three-roller centering device for rolling mill

A centering device and rolling mill technology, applied in the direction of guiding/positioning/alignment devices, etc., can solve the problems of not being able to adapt to various specifications of steel pipes, and the difficulty of biting into steel pipes, so as to achieve high rolling stability and reduce operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

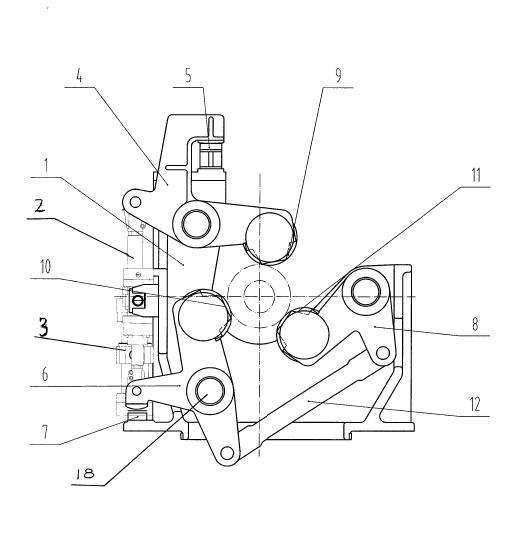

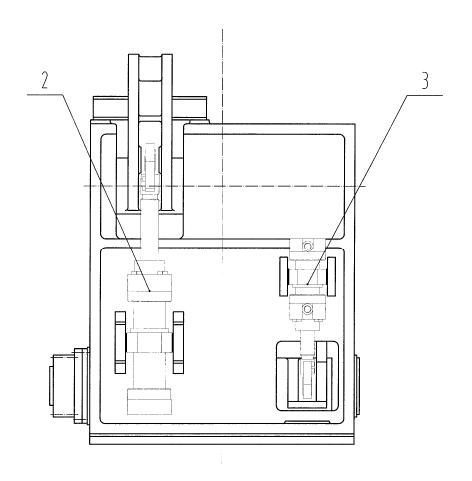

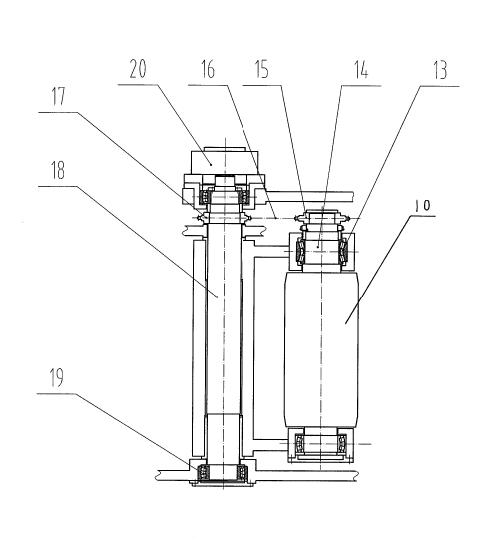

[0011] A three-roll centering device for a rolling mill, comprising a frame 1, an upper guide roller driving cylinder 2 and a lower guide roller driving cylinder 3 respectively fixedly arranged on one side of the frame 1, and L-shaped rollers respectively hinged on the frame 1. The swing arm 4, the T-shaped swing arm 6 and the inverted V-shaped swing arm 8 are provided with a hinge shaft hinged with the frame 1 at the L vertex of the L-shaped swing arm 4, and one end of the L-shaped swing arm 4 is provided with an upper guide Roller 9, between the other end of the L-shaped swing arm 4 and the frame 1 is provided with a first adjustment pad 5 that can adjust its swing range, the upper guide roller drives the output shaft of the cylinder 2 and the L-top of the L-shaped swing arm 4 The corners are hinged together by pin shafts, a hinge shaft 18 hinged with the frame 1 is provided at the cross arm center of the T-shaped swing arm 6, and a movable hinge is provided between the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com