Rolling method for producing phase changes in finish rolling process of low-grade non-oriented silicon steel

A technology of oriented silicon steel and low grade, which is applied in the field of steel rolling to achieve the effects of ensuring safe production, improving rolling stability, and stabilizing deformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: The rolling method of rolling DW60

[0036] After the DW60 casting slab enters the slab warehouse of the hot rolling mill, the slab is checked and received. According to the production plan, the slab is transported by the crane to the feeding roller table of the heating furnace. After weighing and checking, the slab is sent to the front of the designated heating furnace by the roller table according to the furnace loading sequence, and then the slab is loaded by the steel loading machine. The blank is sent into the heating furnace for heating.

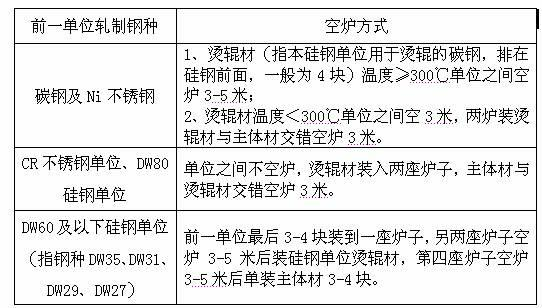

[0037] 1) Carry out empty furnace with other steel types in the heating furnace, the method of empty furnace is as follows:

[0038]

[0039] 2) The furnace temperature control of each section is as follows:

[0040] 1. Heating section: (Target temperature out of the furnace -50) ± 30 ℃

[0041] Second heating section: (Target temperature + 20) ± 30 ℃

[0042] Soaking section: The target temperature of the f...

Embodiment 2

[0054] Embodiment 2: Rolling method of rolling DW47

[0055] After the DW47 casting slab enters the slab warehouse of the hot rolling mill, the slab is checked and received. According to the production plan, the slab is transported by the crane to the feeding roller table of the heating furnace. After weighing and checking, the slab is sent to the front of the designated heating furnace by the roller table according to the furnace loading sequence, and then the slab is loaded by the steel loading machine. The blank is sent into the heating furnace for heating.

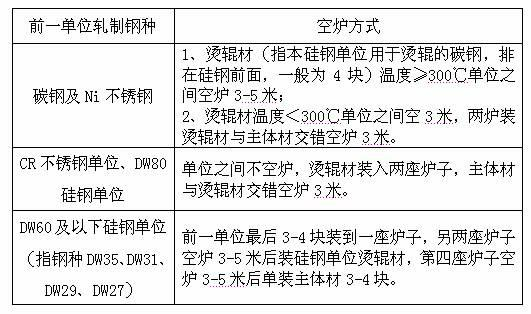

[0056] 1) Carry out empty furnace with other steel types in the heating furnace, the method of empty furnace is as follows:

[0057]

[0058] 2) The furnace temperature control of each section is as follows:

[0059] 1. Heating section: (Target temperature out of the furnace -50) ± 30 ℃

[0060] Second heating section: (Target temperature + 20) ± 30 ℃

[0061] Soaking section: The target temperature of the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com