Mud pump air case

A technology of air bags and mud pumps, which is applied in the direction of pump components, variable displacement pump parts, and parts of pumping devices for elastic fluids, etc. Reduce the overall strength of the body and other problems, achieve good deformation, prolong service life, and fast deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

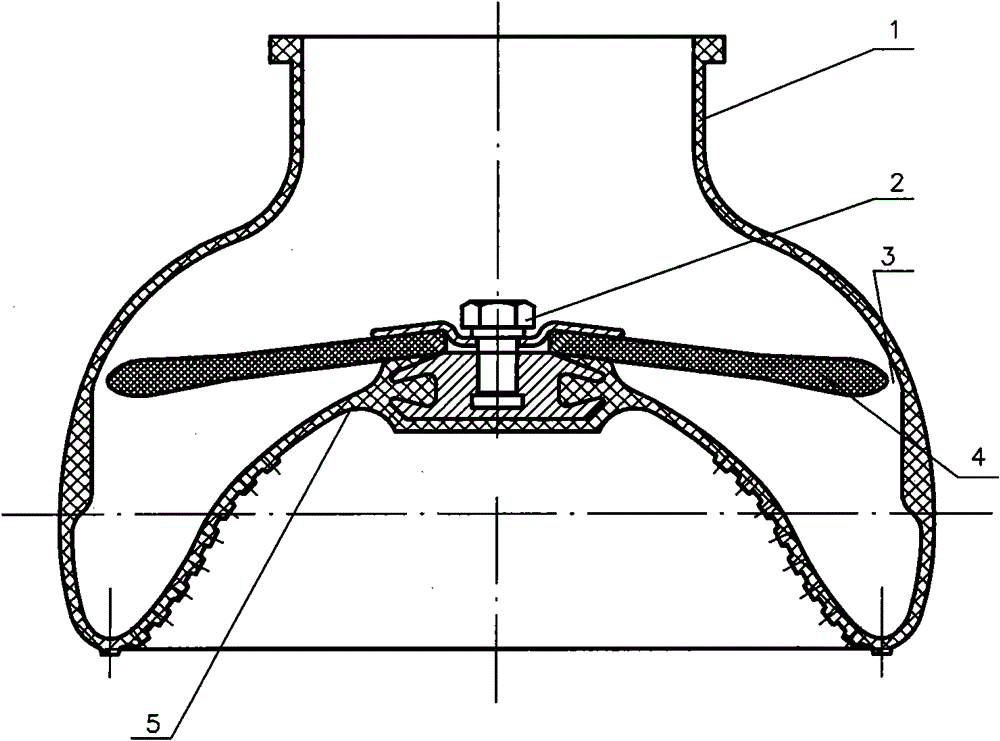

[0015] The present invention as figure 1 As shown: a capsule body 1 with a concave inner bottom surface made of rubber, with a balance board 4 inside the capsule body 1 , and the balance board 4 is fixedly connected to the inner bottom surface of the capsule body 1 .

[0016] A nut 5 is embedded at the center of the inner bottom surface of the capsule body 1 , and the balance plate 4 is fixedly connected to the inner bottom surface of the capsule body 1 through the screw 2 connected with the nut 5 . In order to ensure the connection effect, a pressure plate (acting as a gasket) can be added.

[0017] The diameter of the balance plate 4 is slightly smaller than the inner diameter of the capsule body 1, so that the gap between the balance plate 4 and the inner wall of the capsule body 1 forms a damping air passage.

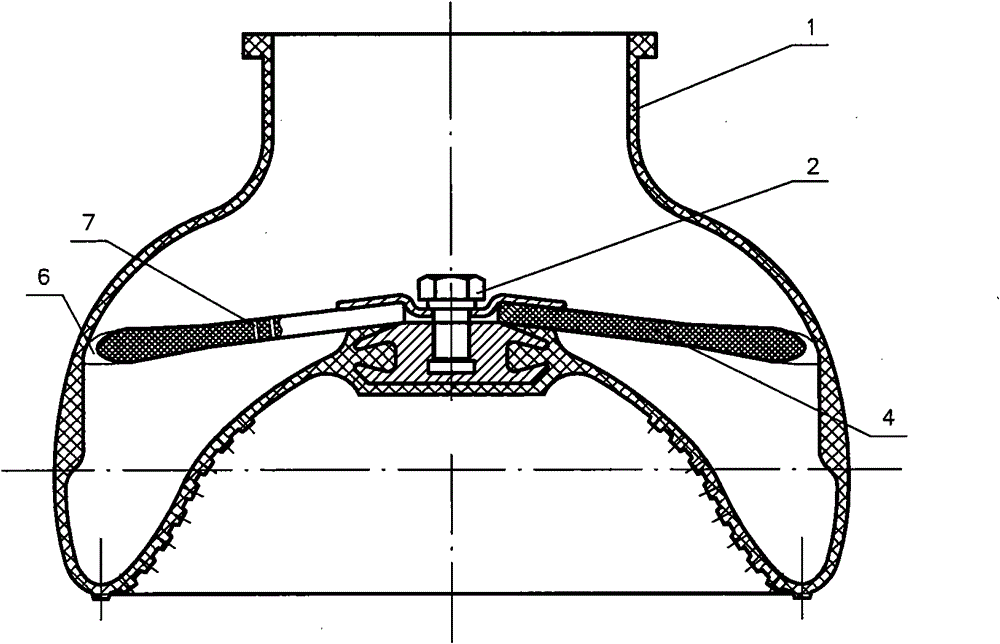

[0018] Another embodiment of the present invention is as figure 2 As shown: the body of the balance board 4 is made of hard material, and the edge of the balance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com