Sheet billet continuous casting and rolling production line

A thin slab continuous casting and production line technology, applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problems of strong production line rigidity and poor surface quality of thin plates, so as to reduce operating costs and reduce factory The effect of investing, increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

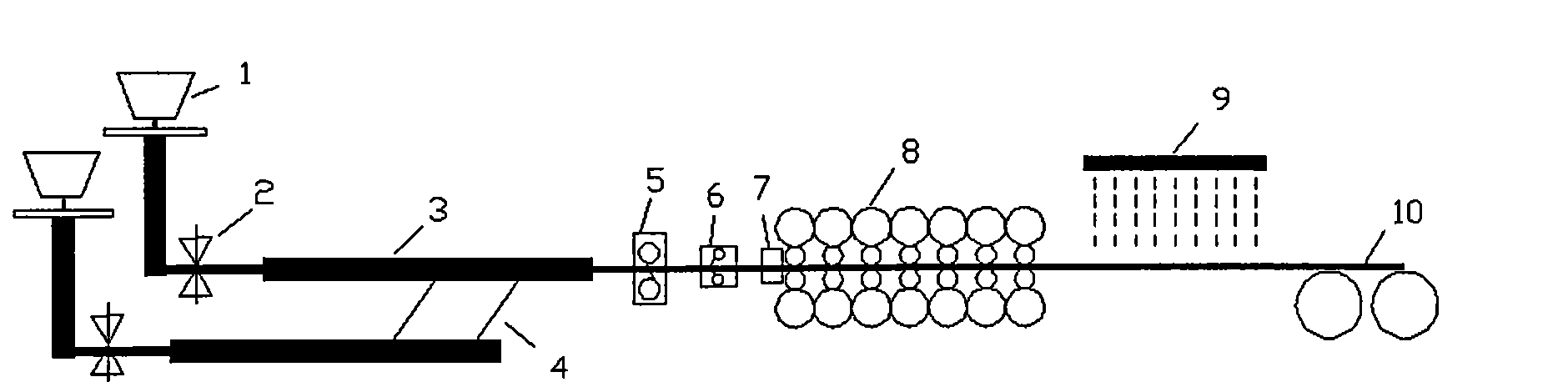

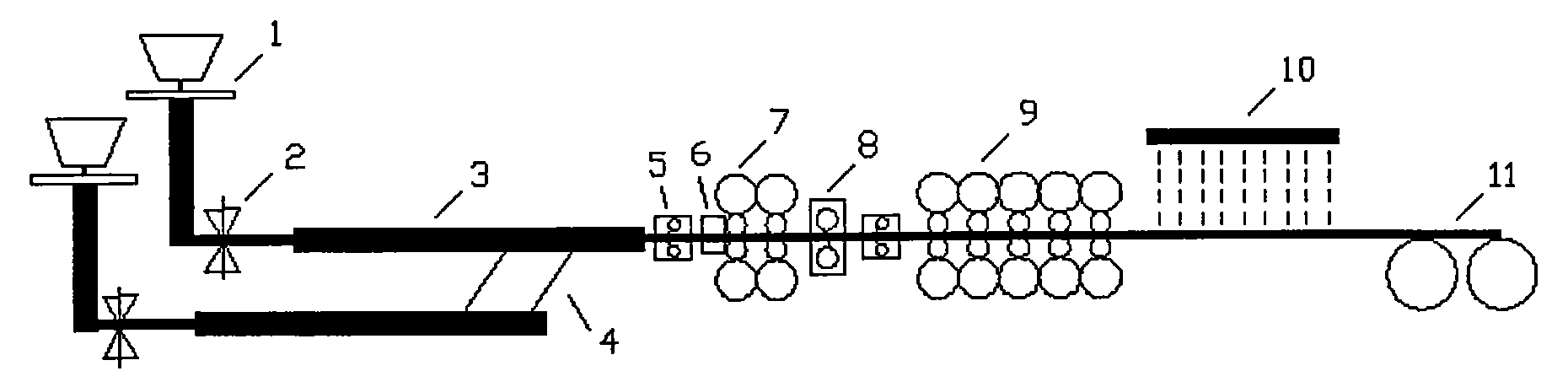

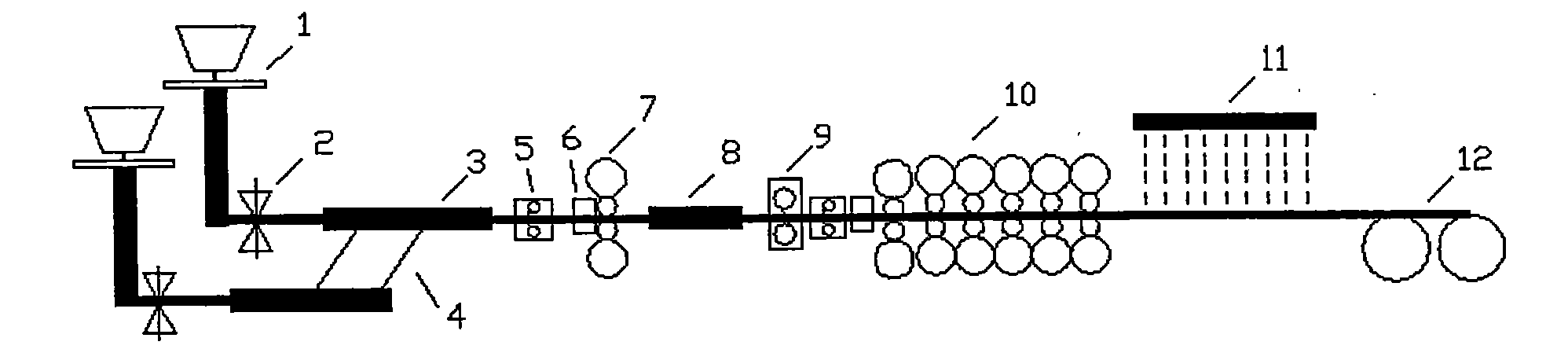

[0039] Production equipment layout of the present invention refers to Figure 4 : Continuous casting machine 1-oscillating shear 2-roller hearth tunnel furnace 3-descaler device 5-vertical roll 6-rough rolling mill 7-hot coil box 8-ultra-fast water cooling device 9-flying shear 10-secondary descaling Device - finishing mill 11 - laminar cooling and ultra-fast water cooling device 12 - coiler 13.

[0040] (1) Continuous casting billet: use one vertical bending or arc continuous casting machine with one machine and two streams or two two machines and two streams to cast a cross-section (50-70mm)×(900-1650mm), and the length of the billet is based on Continuous casting slab for selection of coil weight and coil outer diameter.

[0041] (2) Swing shears: Automatic cutting according to the slab length required by the process.

[0042] (3) Tunnel furnace heating: Roller hearth tunnel furnace is adopted. The furnace length is determined according to the maximum casting speed of con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com