Pavement self-adaptive rhombic moonmobile moving system

A mobile system and lunar rover technology, which is applied in the field of road adaptive diamond lunar rover mobile system, can solve the problems of weak climbing and obstacle crossing ability, inability to give full play to motor efficiency, poor vehicle body stability, etc., and achieve good mobile stability. stability, good off-road performance, the effect of reducing the roll angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

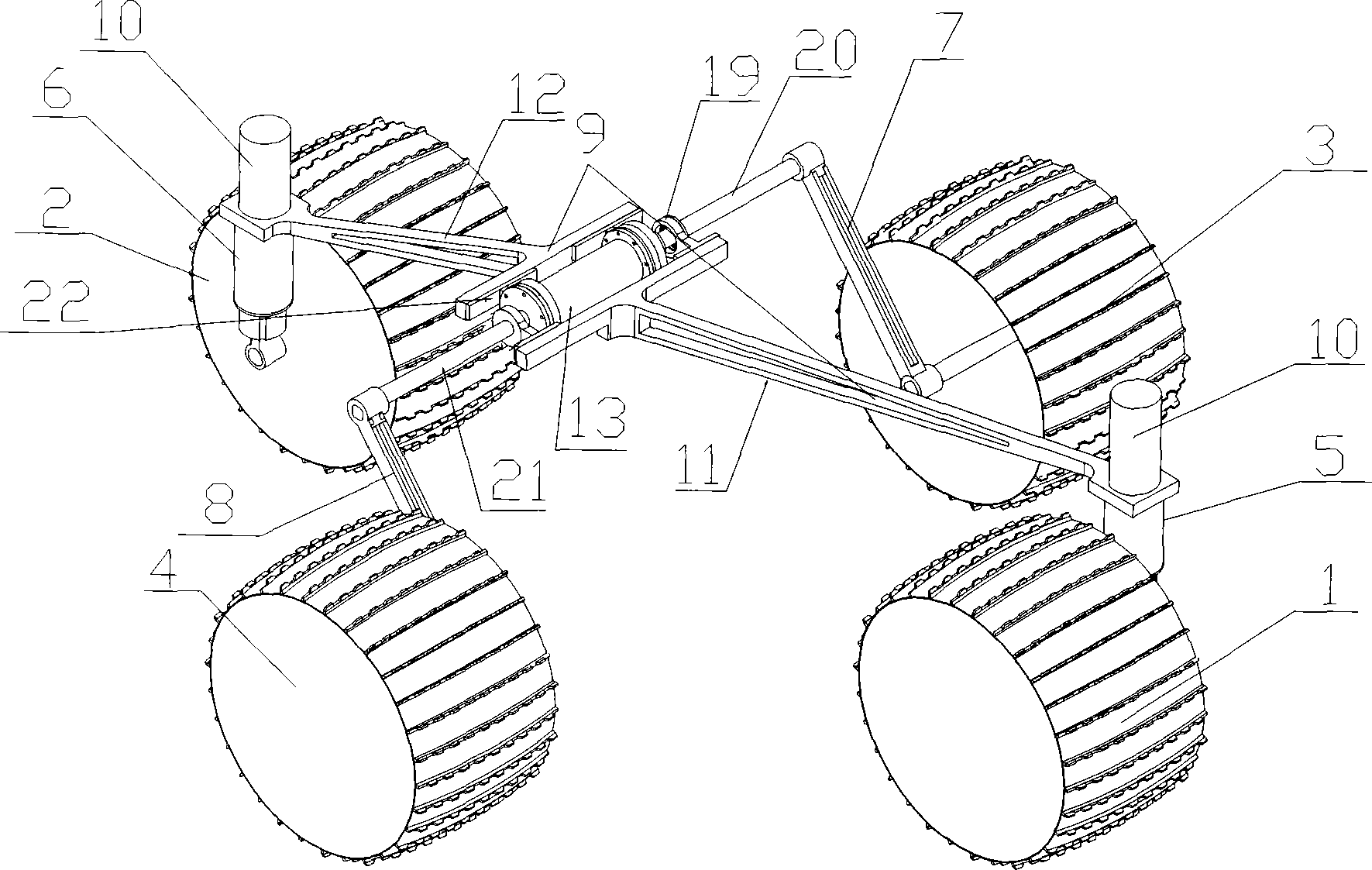

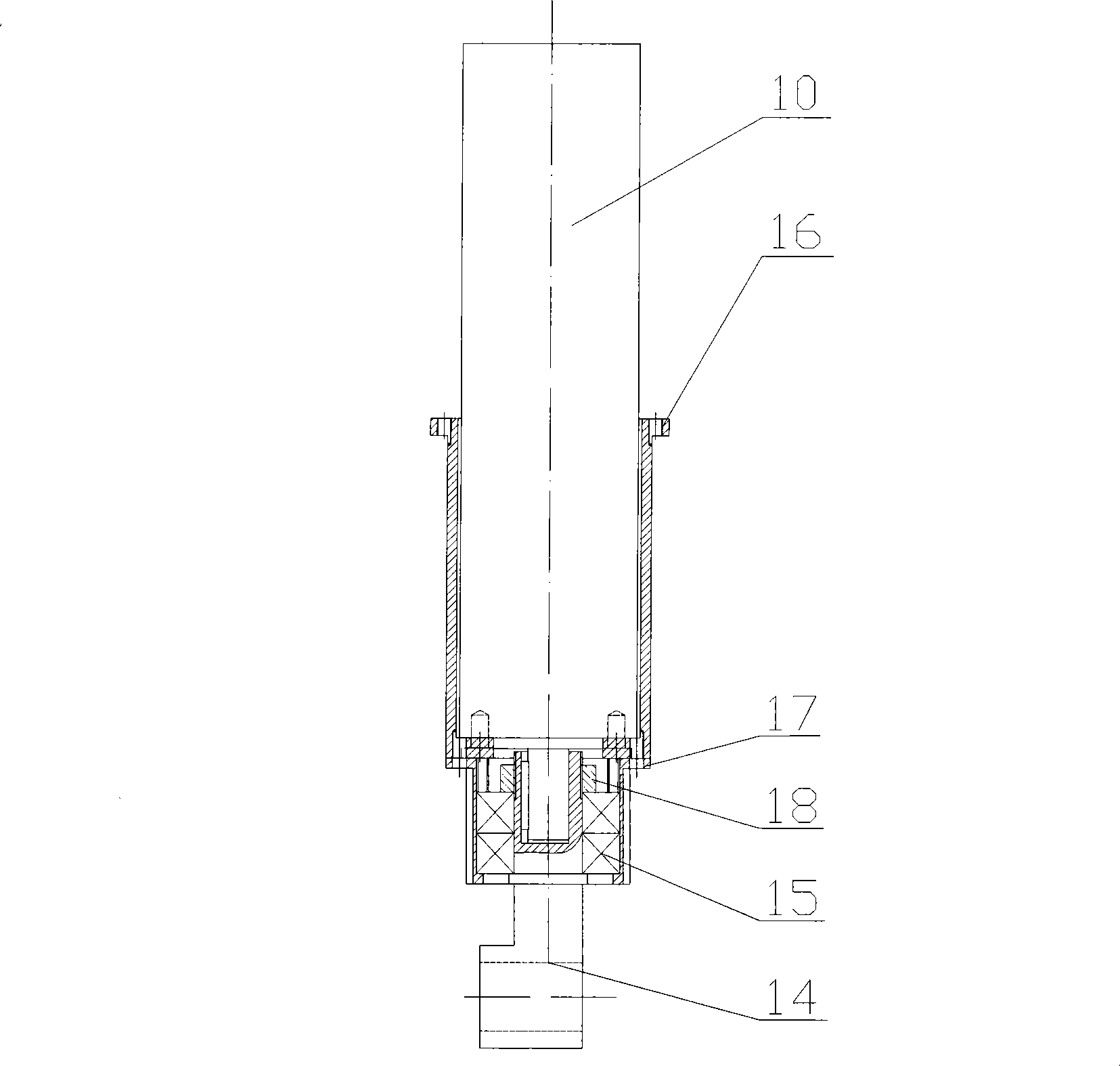

[0029] Such as figure 1 , figure 2 Shown, the road surface self-adaptive rhombic lunar rover mobile system of the present invention, it comprises rotatable vehicle frame 9 and is installed on vehicle frame 9 the front wheel 1 of rhombus arrangement, trailing wheel 2, left wheel 3 and right wheel 4, front wheel 1 and the rear wheel 2 are respectively fixed on the vehicle frame 9 through the front suspension system 5 and the rear suspension system 6, the left wheel 3 and the right wheel 4 are respectively fixed on the left suspension system 7 and the right suspension system 8, and the vehicle frame 9 It includes the front frame 11 with the front wheel 1 installed, the rear frame 12 with the rear wheel 2 installed, the articulated bearing seat 19, the left articulated shaft 20, the right articulated shaft 21, the motor 13, the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com