Concave elastic screen wheel

An elastic sieve and concave surface technology, applied in the field of deep space exploration, can solve the problems of affecting the load of detection instruments and a large amount of dust, and achieve the effect of reducing the amount of subsidence, reducing dust, and suppressing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

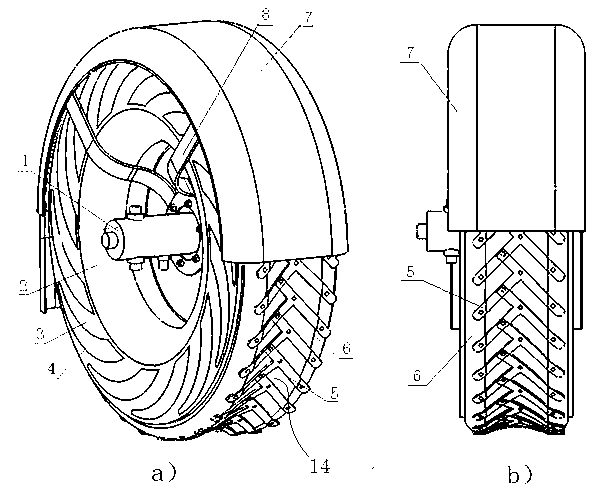

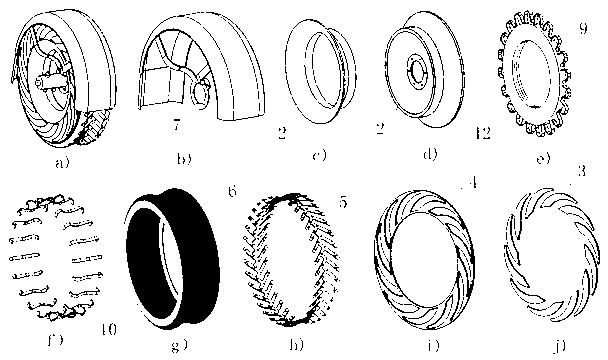

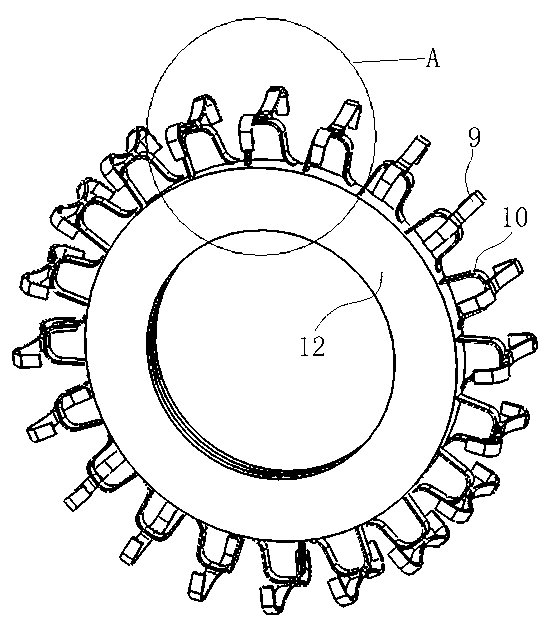

[0037] The present invention will be further described in detail in conjunction with the accompanying drawings and the specific embodiment of the manned lunar vehicle wheel.

[0038] Such as figure 1 , figure 2 with image 3As shown, the concave elastic screen wheel of the present invention includes a protective plate 7, a protective plate support 8, an anti-skid pawl 5, a wire mesh 6, a spring leaf 9, a support ring 12, a bow frame 10, a crescent-shaped wheel spoke 3, an elastic foam Filler plate 4, hub 2, support ring 12 and drive motor 1. The driving motor 1 is installed in the center of the hub 2 and is the driving part of the wheel. The wheel hub 2, the crescent-shaped spokes 3, the support ring 12, the spring leaf 9 and the bow frame 10 play a main supporting role. The hub 2 is rigidly connected to the support ring 12 . The fixed end 13 of the leaf spring 9 is fixed on the support ring, and the free end 11 of the spring leaf is attached to the surface of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com