low fuel consumption vehicle

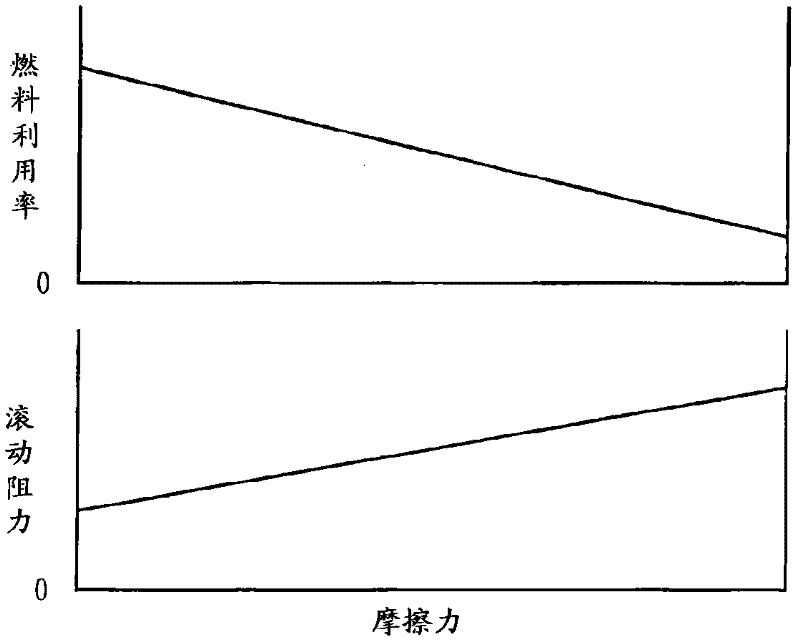

A low fuel consumption, vehicle technology, applied in vehicle components, elastic suspension, tire tread/tread pattern, etc., can solve the problems of reduced turning performance, reduced braking performance, small friction coefficient, etc., to improve turning performance, The effect of suppressing the reduction in driving feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In this case, a vehicle that is a fuel-efficient vehicle will be described.

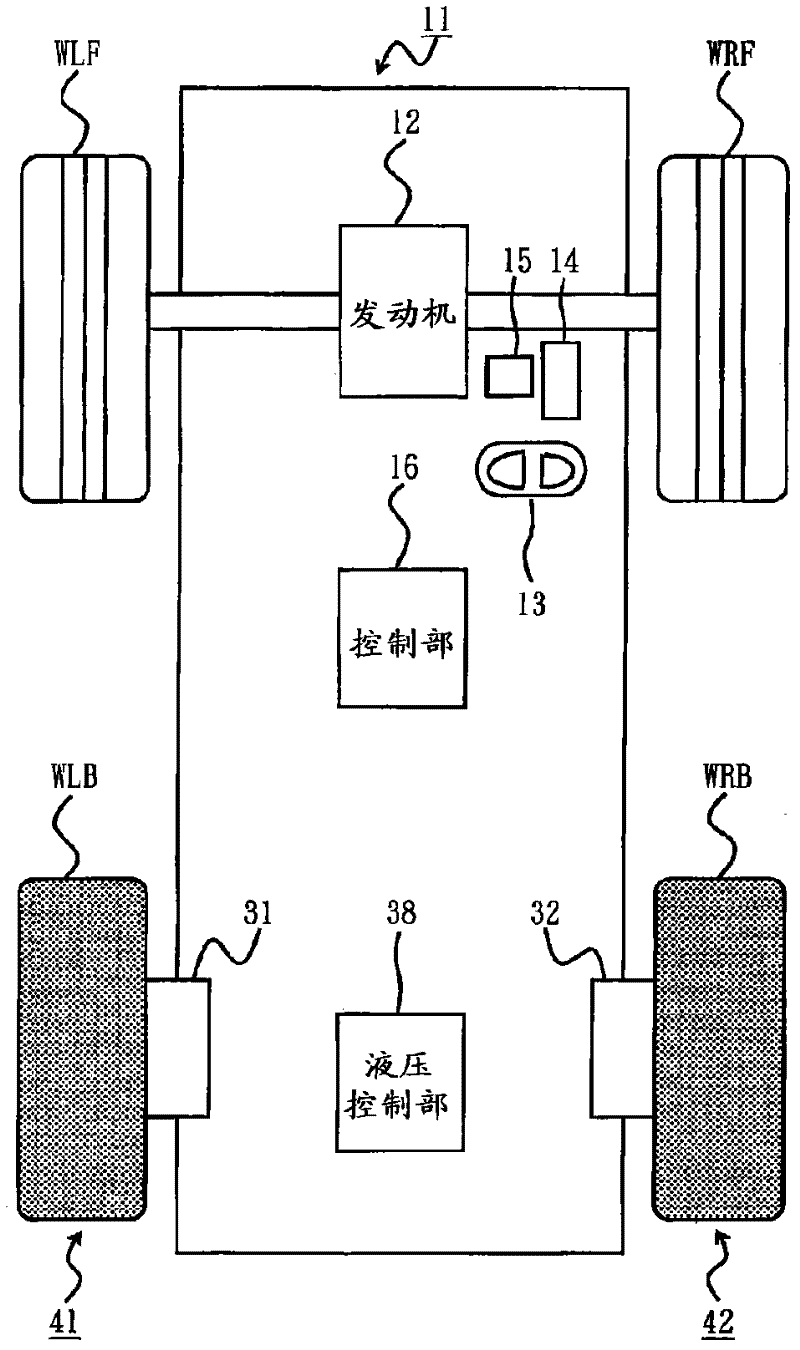

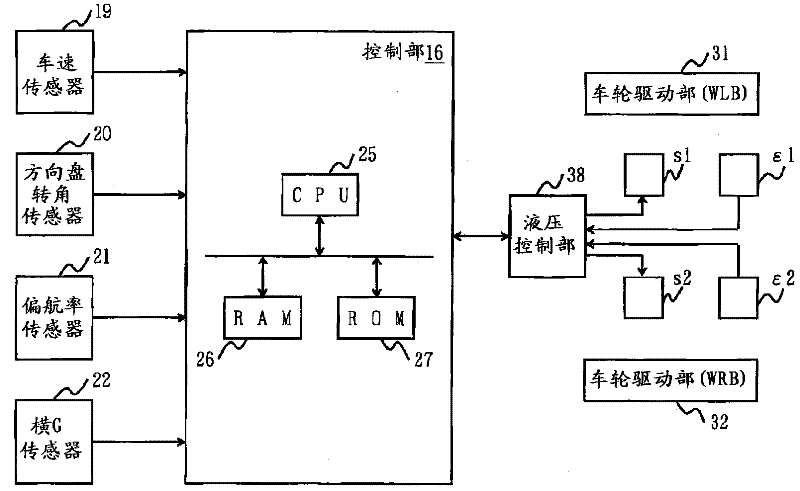

[0053] figure 1 It is a conceptual diagram of a vehicle according to an embodiment of the present invention.

[0054]In the figure, 11 is a vehicle body showing the main body of the vehicle, 12 is an engine as a driving source, and WLF, WRF, WLB, and WRB are front left, front right, and rear left rotatably arranged with respect to the above-mentioned vehicle body 11. As for the wheels on the side and the rear right side, the front wheels are constituted by the wheels WLF and WRF, and the rear wheels are constituted by the wheels WLB and WRB. By driving the above-mentioned engine 12 , the wheels WLF, WRF are rotated in conjunction with each other to function as drive wheels, and the wheels WLB, WRB are driven to rotate as the vehicle travels.

[0055] In addition, 13 is a steering wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com