Tenoning assist mechanism

An auxiliary mechanism and tenoning technology, which is applied in the direction of mortising machines, slotting machines, wood processing equipment, etc., can solve the problems of insufficient tenoning stability and scattered pressing force, so as to achieve a compact overall structure and provide The effect of tenoning precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

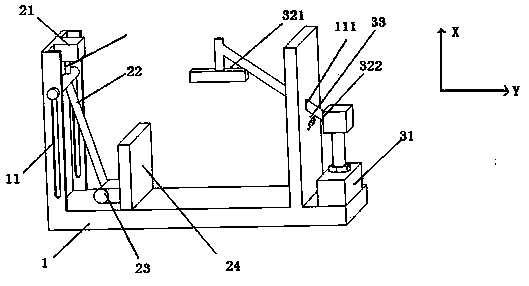

[0030] like figure 1 , the tenoning auxiliary mechanism includes a U-shaped workbench frame 1 , a first mechanism 2 , and a second mechanism 3 . The first mechanism 2 and the second mechanism 3 are respectively arranged on the two longitudinal sides of the U-shaped workbench frame 1, wherein the first mechanism 2 includes a first cylinder 21, a movable part 22, a push bar 23, a push block 24. The second mechanism 3 includes a second cylinder 31 and a rotating rod 32 , and the two ends of the rotating rod 32 respectively have a clamping plate 321 and an action plate 322 .

[0031] A first mechanism is arranged on a longitudinal side of the U-shaped workbench frame 1, and the first cylinder 21 faces the movable part 22, and an annular ring can be arranged at the end of the first cylinder 21, that is, the end of its contact surface with the movable part 22. co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com