Tenoning clamping mechanism

A clamping mechanism and tenoning technology, applied in the direction of mortising machines, slotting machines, wood processing equipment, etc., can solve the problems of scattered pressing force and insufficient tenoning stability, and achieve simple structure and provide tenoning Accuracy, Quantity Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

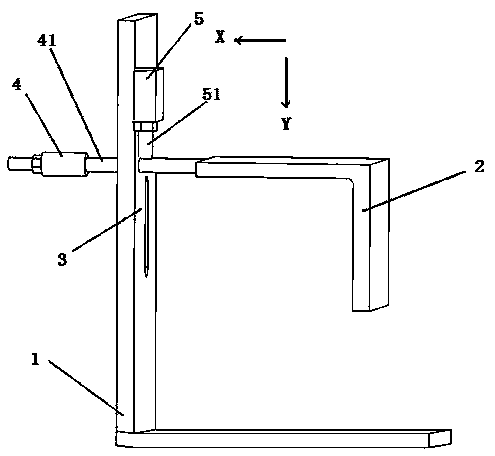

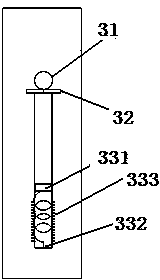

[0033] Such as figure 1 , The tenon clamping mechanism includes an L-shaped workbench frame 1, a pressing plate 2, a first cylinder 4, and a second cylinder 5. A movable area 3 is provided on the longitudinal side of the workbench frame 1, and the movable area 3 includes a horizontal movable hole 31, a telescopic baffle 32 and a longitudinal movable groove 33. The pressing plate 2 is an integrally formed ??-shaped structure, the lateral side of the pressing plate 2 is connected with the cylinder shaft 41 of the first cylinder 4, and the cylinder shaft 42 of the first cylinder 41 passes through the Horizontal movable holes 31 are provided. The second cylinder 5 is arranged longitudinally on the workbench frame 1, and its second cylinder shaft 51 is directly above the first cylinder shaft 41. In order to make the second cylinder shaft 51 apply uniform and stable pressure to the first cylinder shaft 41 In the case of longitudinal force, an arc-shaped part is provided at the end o...

Embodiment 2

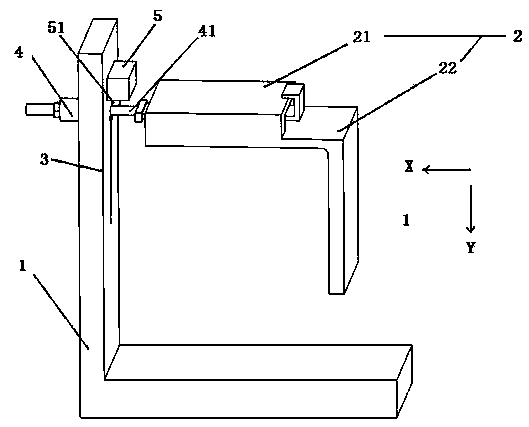

[0037] Such as figure 2 The tenon clamping mechanism includes an L-shaped workbench frame 1, a pressing plate 2, a first cylinder 4, and a second cylinder 5. A movable area 3 is provided on the longitudinal side of the workbench frame 1, and the movable area 3 includes a horizontal movable hole 31, a telescopic baffle 32 and a longitudinal movable groove 33. The pressing plate 2 includes a groove part 21 and a ??-shaped structure 22, both of which are integrally formed and detachable structures. The groove part 22 is arranged on the upper side of the lateral side of the pressing plate 2 and is connected to the first cylinder 4, and a gusset plate that is fitted with the groove part 22 is fixedly connected to the first cylinder shaft 41 side. When the tenon clamping mechanism works, the pressing plate 2 and the buckle plate are connected in cooperation. The cylinder shaft 41 of the first cylinder 4 is arranged transversely through the horizontal movable hole 31, the second cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com