Linear compressor

A linear compressor, fixed mechanism technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc. Improve assembly flexibility, improve reliability, and ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

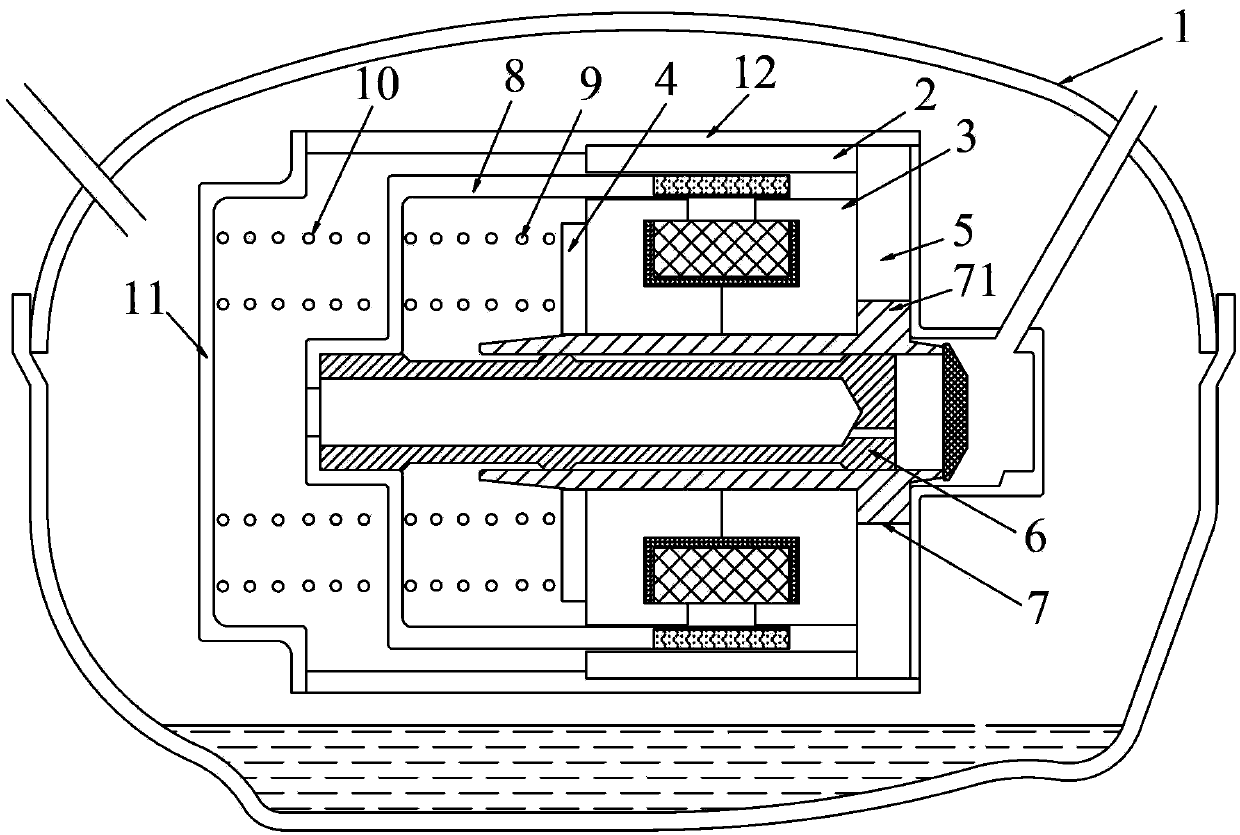

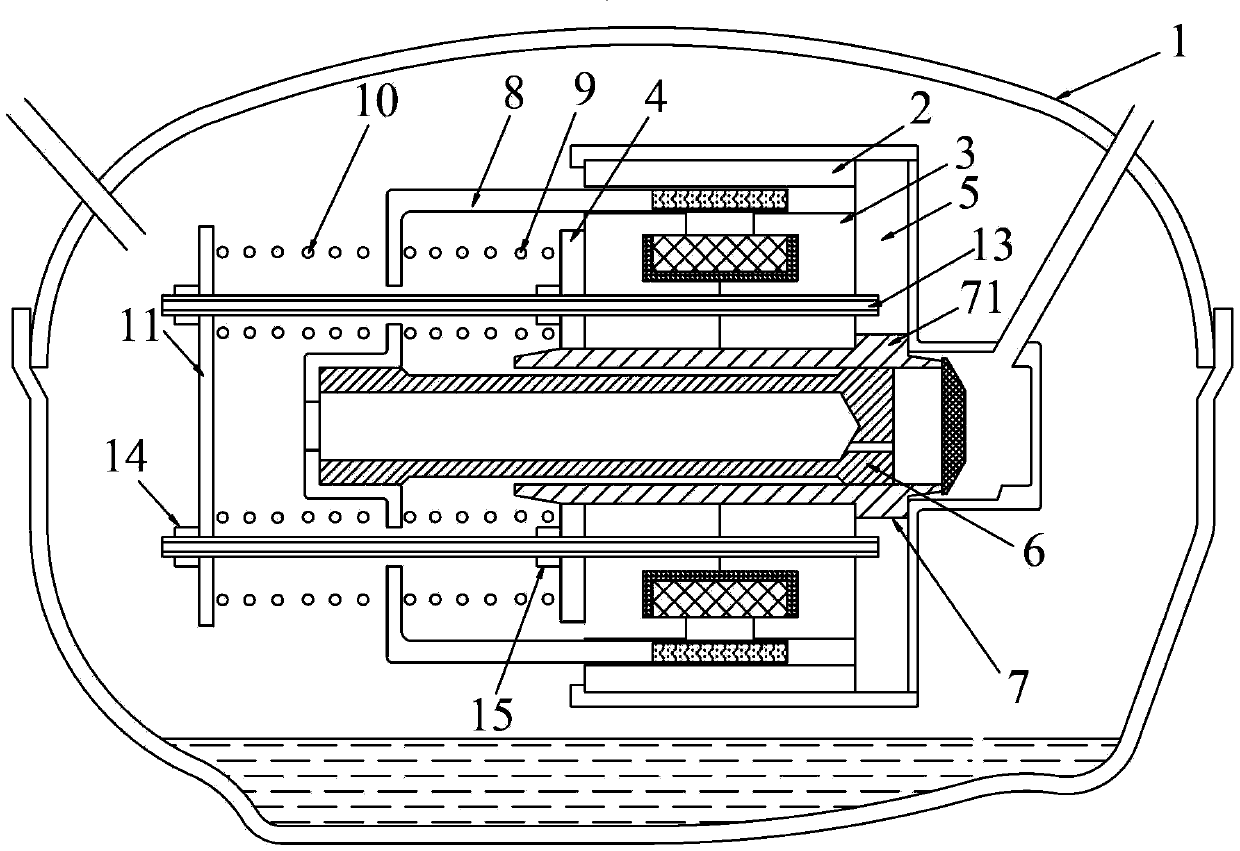

[0027] Refer below Figure 2~Figure 8 Shown is a detailed description of the specific implementation of the linear compressor of the present invention.

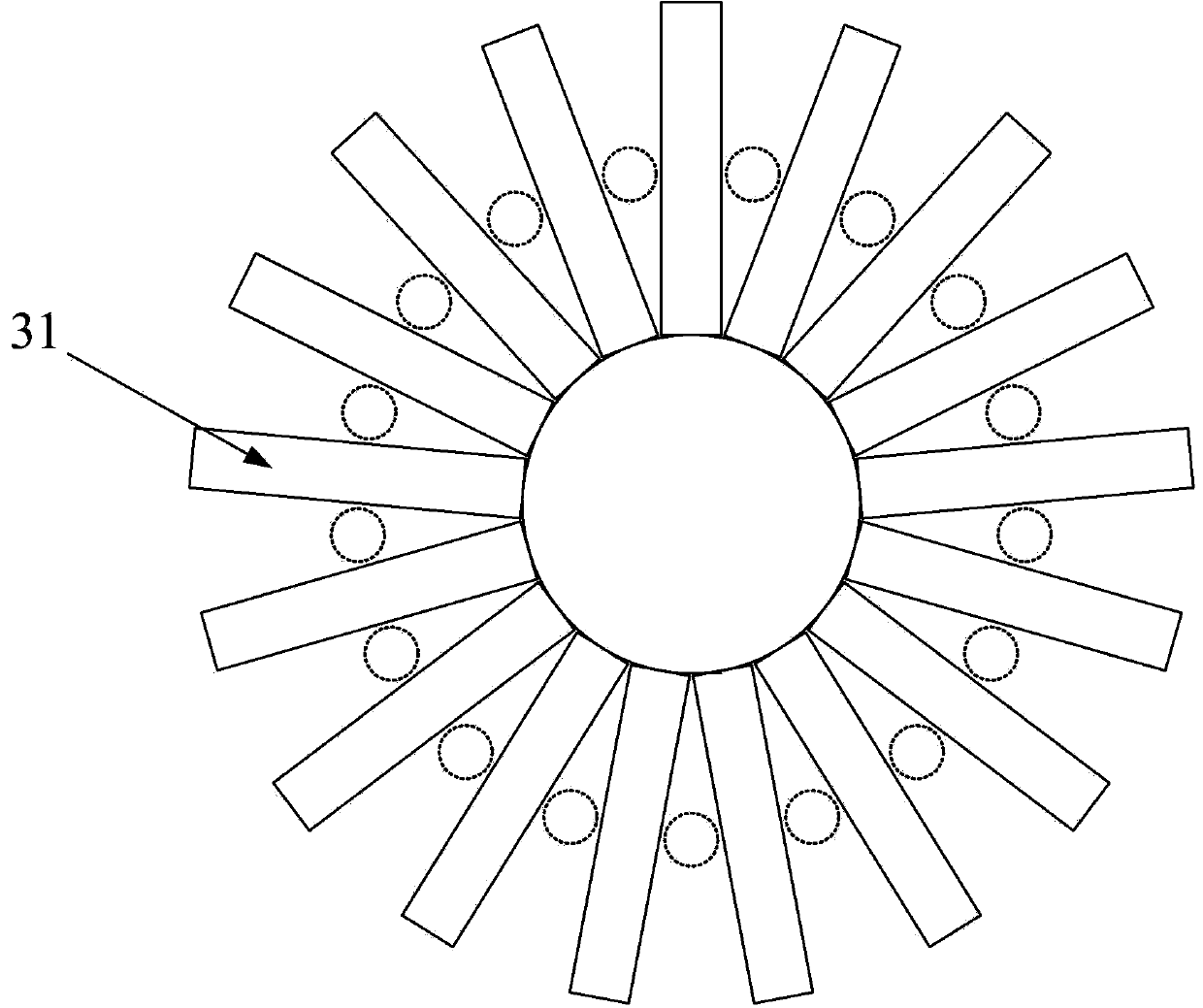

[0028] figure 2 and image 3 It is a structural schematic diagram of the linear compressor in the present invention, which is the first embodiment. Such as figure 2 and image 3 As shown, the cylinder 7 is a long-axis cylinder, that is, the axial length of the cylinder body of the cylinder 7 is greater than the axial length of the inner stator 3 . A flange 71 extending radially outward is formed on the outer peripheral surface of the cylinder 7 at the right end thereof, and the flange 5 is disposed on the outer peripheral surface of the flange 71 . The cylinder body of the air cylinder 7 protrudes into the inner stator 3 , and the outer peripheral surface of the cylinder body is in contact with the inner surface of the inner stator 3 . The right end surface of the inner stator 3 abuts against the left surface of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com