Modularized rapid-installation-type unloading and external protecting integrated system for fabricated building

A modular, quick-installed technology, applied in the processing of building materials, construction, building structure, etc., can solve the problem of the window opening or the top beam of the door opening to be arranged in the outer wall, the danger of steel cutting operation, and the trouble of on-site operators. and other problems, to achieve the effect of improving traction stability and work reliability, improving safety protection effect, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

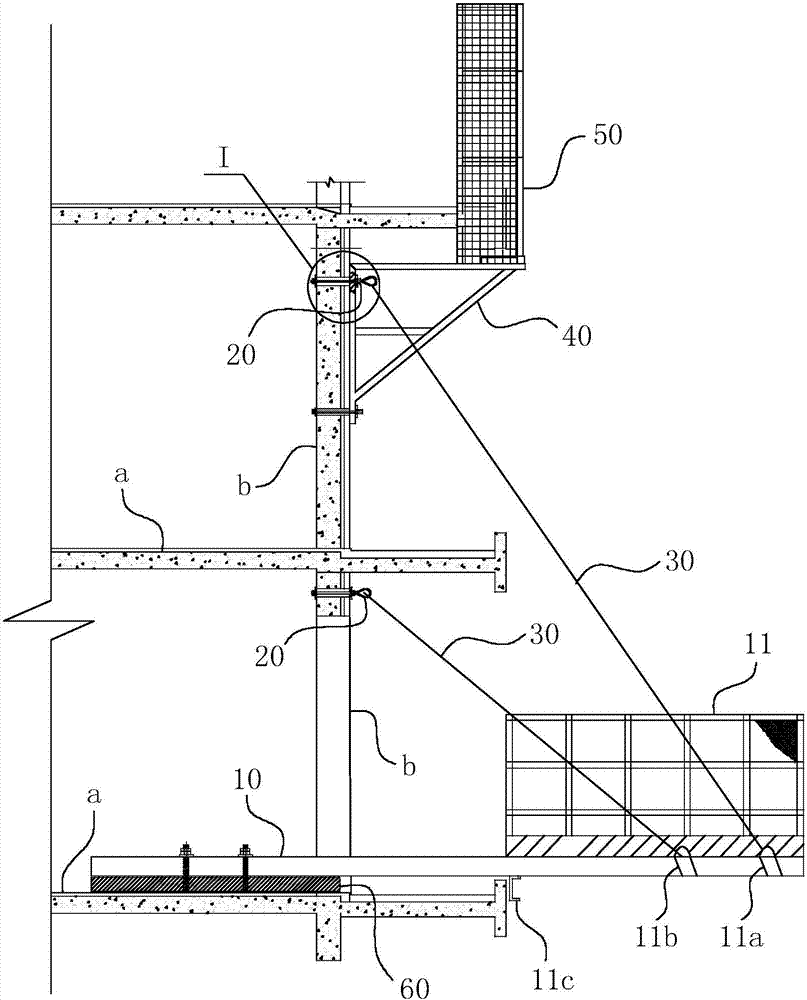

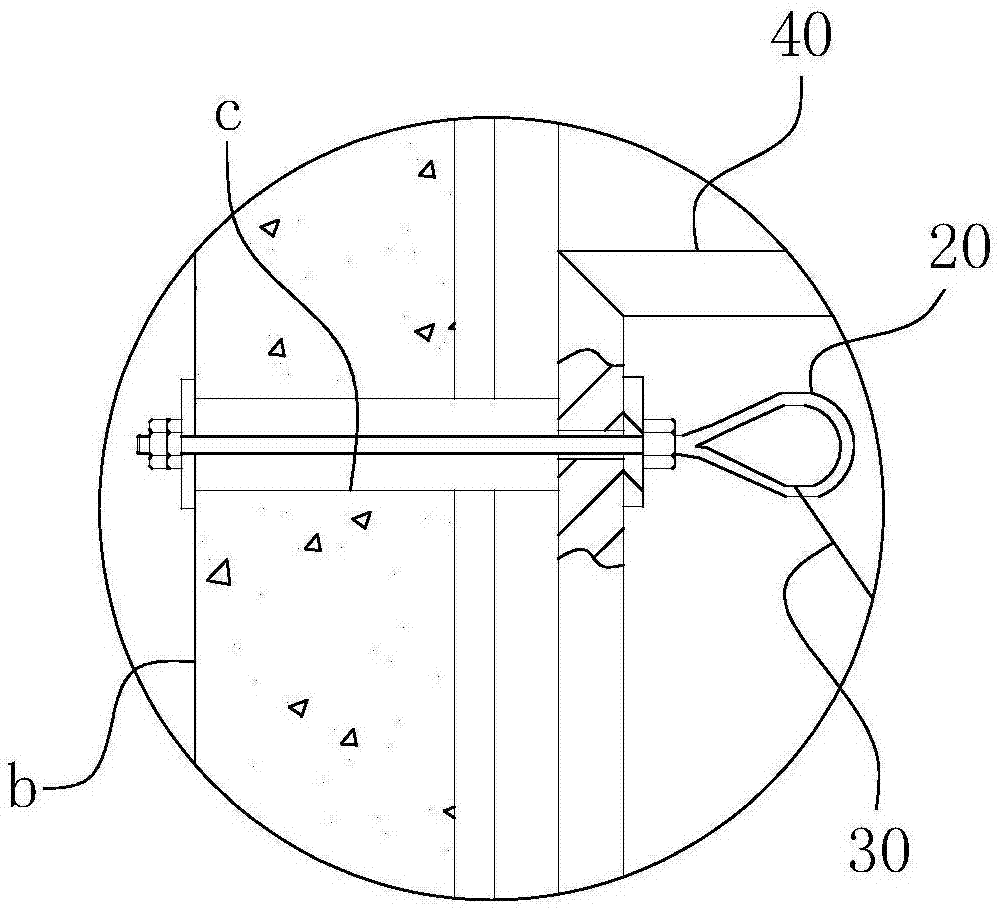

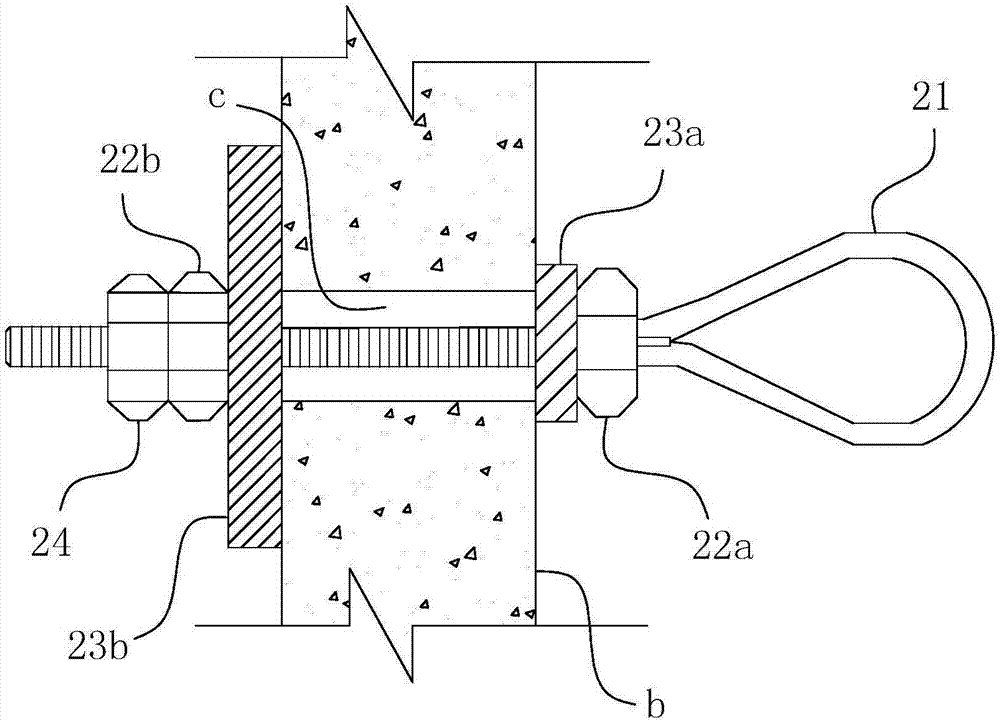

[0032] For ease of understanding, the attached Figure 1-4 , the concrete structure and working mode of the present invention are further described as follows:

[0033] The specific structure of the present invention refers to figure 1 As shown, its main structure consists of an external hanger 50 , a support frame 40 , a steel platform 10 and an anchor ring 20 . Wherein, the steel platform 10 can adopt such as Figure 4 As shown in the platform structure, the fixed end of the steel platform 10 is extended to the place where the counterweight beam 60 is placed on the upper surface of the structural floor a, so as to form a bolt connection between the two. As for the cantilever section 11 of the steel platform 10, it extends out of the balcony of the current floor structure floor, so as to realize the shelving and transfer operations of materials.

[0034] On the basis of the above structure, such as figure 1 As shown, the present invention symmetrically arranges the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com