Numerical control noodle maker

A noodle press machine and frame technology, applied in the direction of dough sheeter/rolling machine/rolling pin, etc., can solve the problems of personal injury, uneven gluten network of dough, high labor intensity of staff, etc., and achieve uniform pressing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

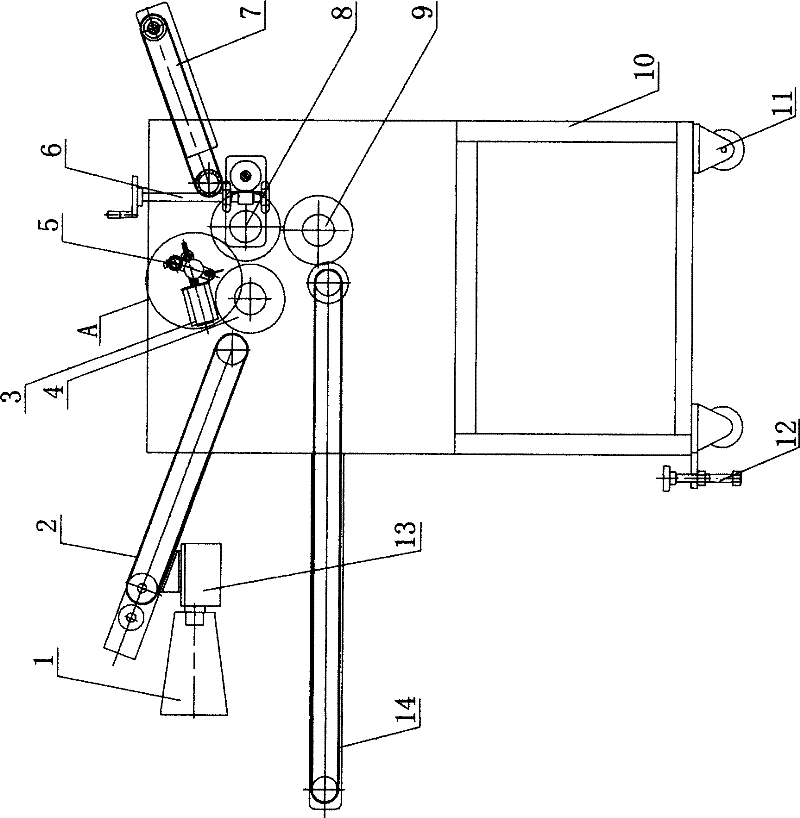

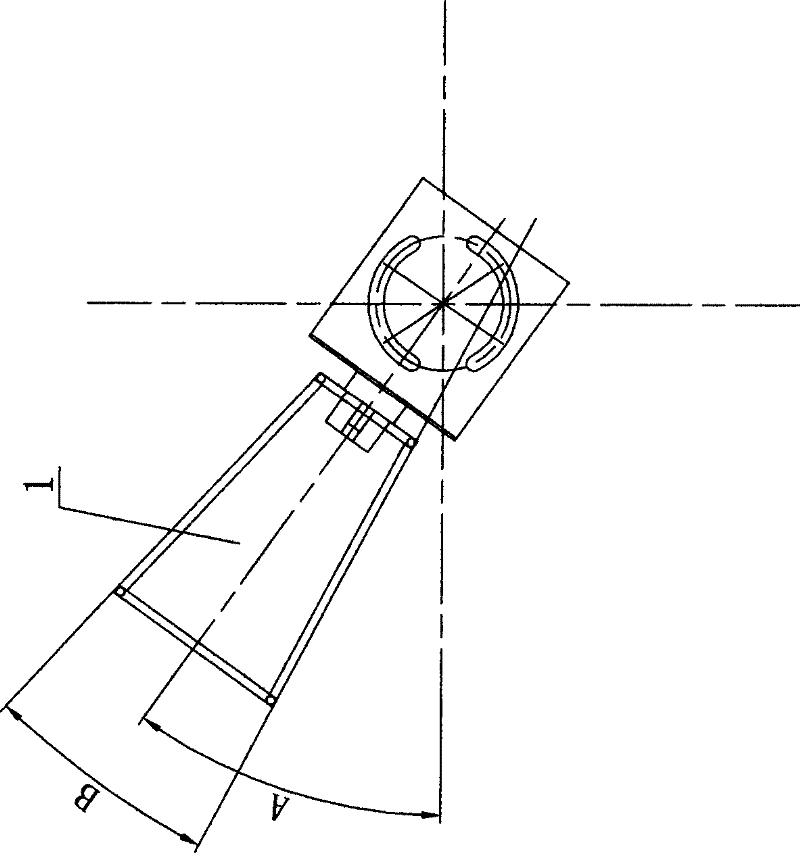

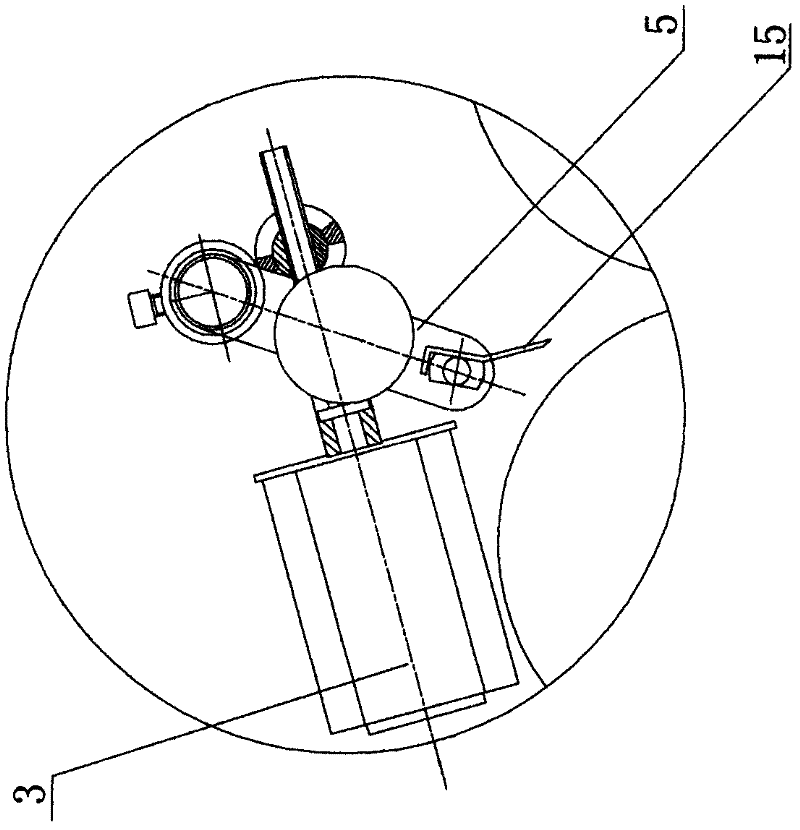

[0015] Such as figure 1 and figure 2 As shown, the CNC noodle press of the present invention comprises a frame, one side of the frame 10 is provided with an upper conveyor belt 2 and a lower conveyor belt 14, and the other side of the frame 10 is provided with a dough output conveyor belt 7. The upper conveyor belt 2 is located above the lower conveyor belt 14 and is inclined upwards. The dough turning roller 1 is provided below the upper conveyor belt 2. The upper conveyor belt 2, the lower conveyor belt 14 and the dough output The frame of the conveyor belt 7 is respectively provided with an upper roller 4, a lower roller 9 and an adjustable roller 8, and above the upper roller 4 and the adjustable roller 8 is provided a guide surface device capable of swinging left and right 5. The dough turning roller 1 is placed obliquely, the angle A between it and the horizontal line is 60-90°, the dough turning roller 1 is conical, and the taper B of the dough turning roller 1 is 10-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com