Multi-station balanced pressing mechanism for gas-liquid conversion cylinder

A technology of gas-liquid conversion and pressing mechanism, which is applied to metal processing machinery parts, positioning devices, manufacturing tools, etc., and can solve problems such as uneven product quality and balanced pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

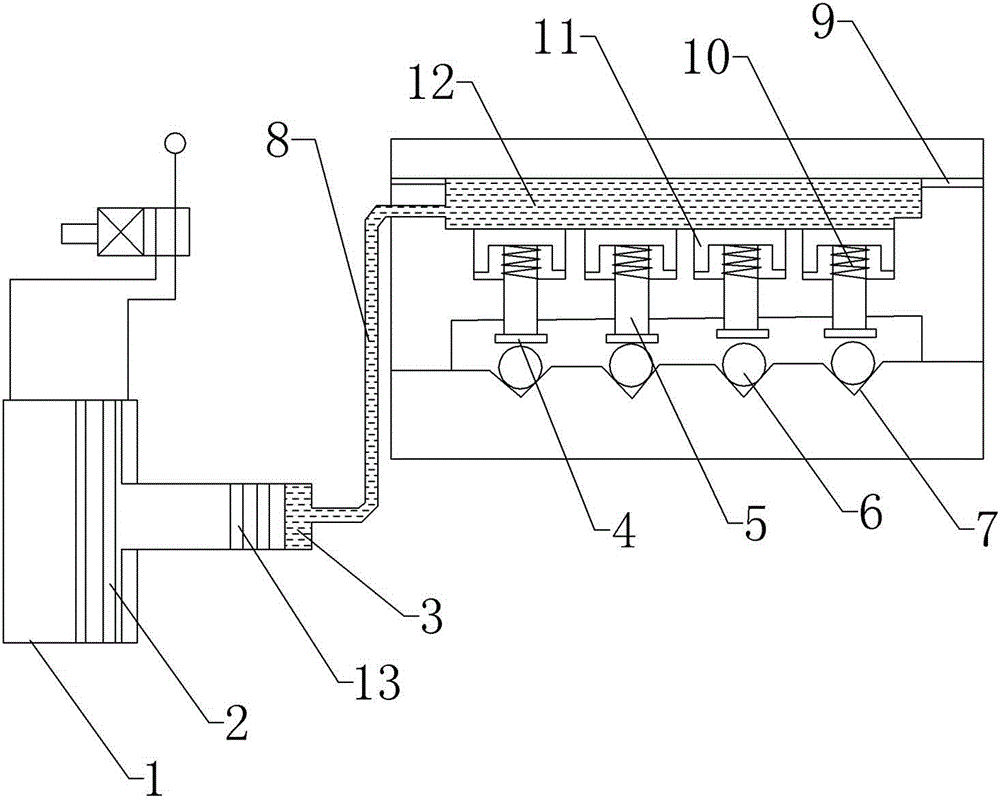

[0014] The reference signs in the drawings of the description include: cylinder 1, first gasket 2, oil cylinder 3, pressure plate 4, piston rod 5, workpiece 6, V-shaped groove 7, pipeline 8, third gasket 9, return spring 10 , sealing ring 11, hydraulic oil 12, second gasket 13.

[0015] Taking keyway milling of shaft workpieces as an example, the implementation is basically as attached figure 1 As shown: the gas-liquid conversion cylinder multi-position balanced pressing mechanism in this embodiment includes a base, the base includes a lower workbench and side guide seats, and four workbenches for clamping workpieces are arranged on the upper part of the workbench. Each station has a V-shaped groove. There are four vertical guide grooves on the side of the guide seat.

[0016] In this embodiment, the cylinder, the oil cylinder and the oil chamber jointly constitute the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com