A kind of pressing force control device for crtsⅢ type turnout plate

A technology for controlling device and pressing force, which is applied in the field of self-compacting concrete pouring for turnout slabs, and can solve the problems of corrosion of fastening screw and adjusting nut, affecting the accuracy of pressing force, and inaccurate torque wrench, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

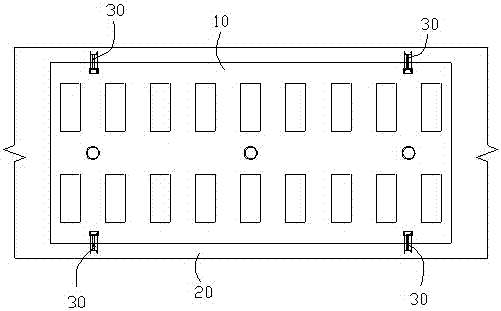

[0019] like image 3 and 4 As shown, the turnout plate 10 is arranged on the base plate 20, and the pressing force control device 30 is arranged on the four corners of the turnout plate 10, and is symmetrically arranged above the base plate on the side of the turnout plate, and is used to control the turnout plate. The compression force, thereby reducing the floating amount of the turnout plate during the self-compacting concrete pouring process.

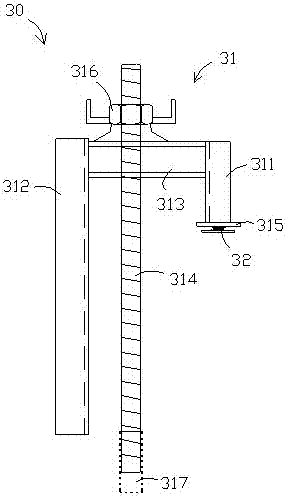

[0020] like figure 1 As shown, the pressing force control device 30 includes a pressing mechanism 31 and a pressing force measuring mechanism 32, and the pressing mechanism 31 includes a force transmission support plate 311, a force transmission support plate 312 and a force transmission support plate for connecting the force transmission support. The horizontal support plate 313 of the plate and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com