Sealing structure of valve chamber cover

A technology of sealing structure and valve chamber, which is applied to the sealing device, casing, machine/engine, etc. of the engine, and can solve the problems of poor sealing, different pressing force of rubber gaskets, uneven distribution of tightening force of rubber gaskets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

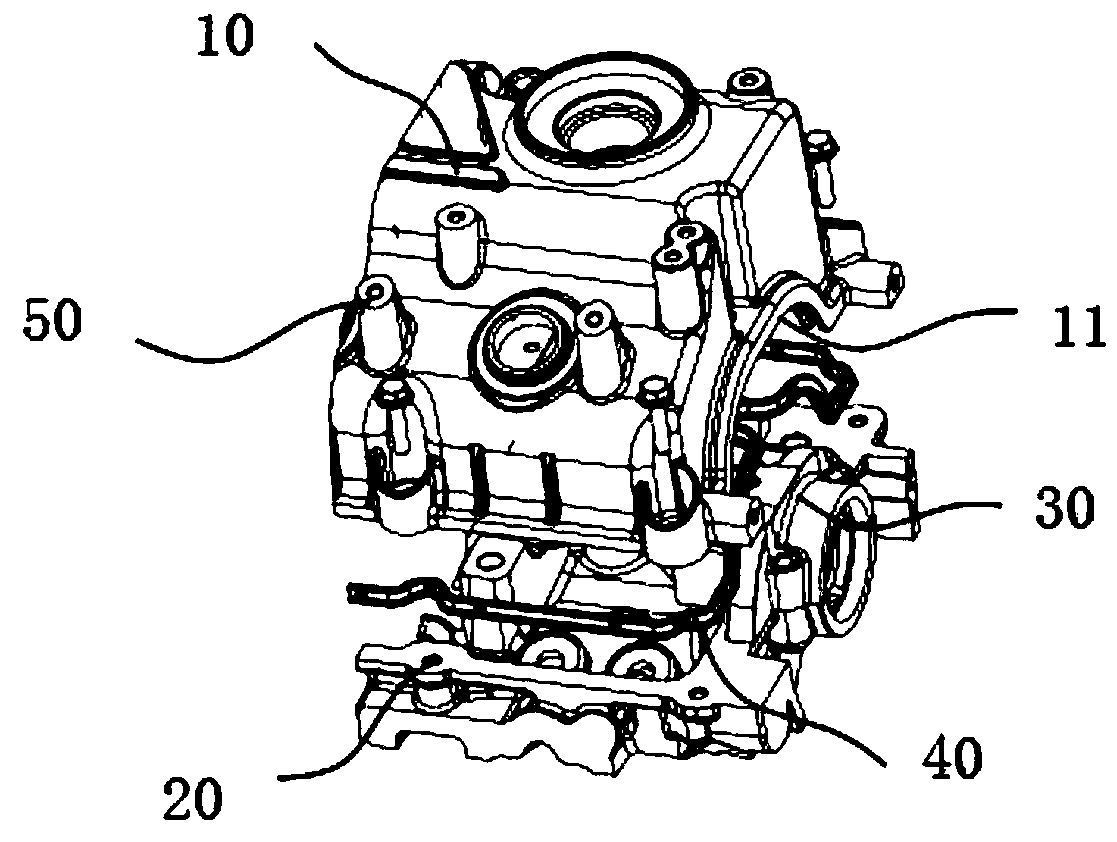

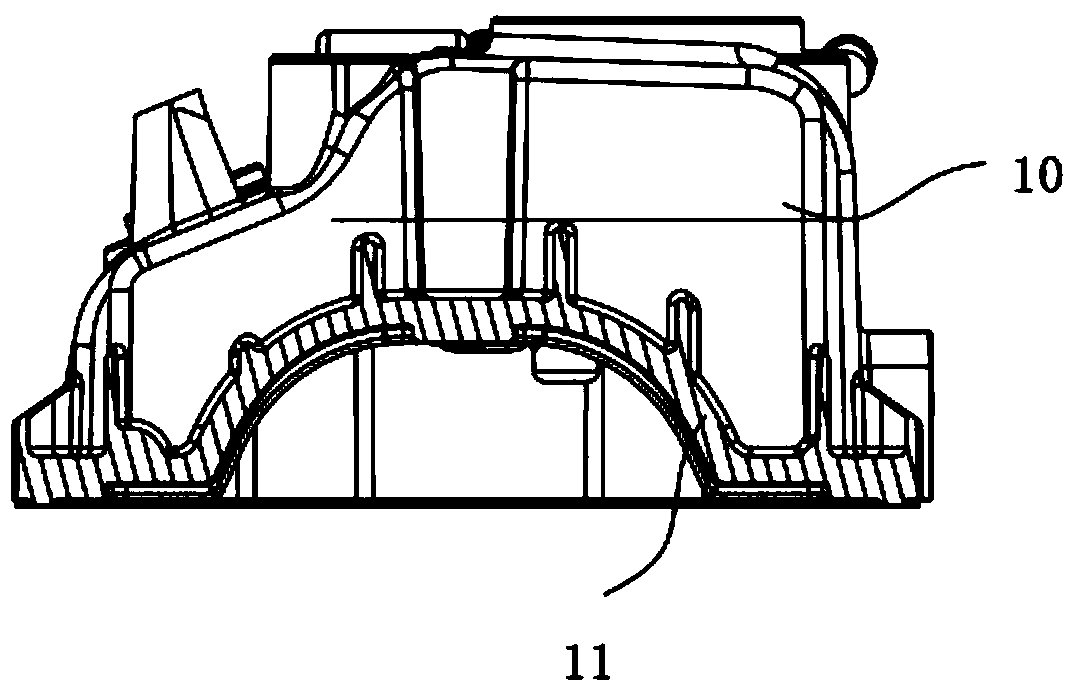

[0009] combine figure 1 , 2 As shown, a sealing structure of a valve chamber cover includes a valve chamber cover 10 and a cylinder head 20, and a camshaft bearing cap 30 located in the chamber surrounded by the valve chamber cover 10 and the cylinder head 20 protrudes outside the chamber , The joint surface of the valve chamber cover 10, the cylinder head 20, and the camshaft bearing cover 30 is provided with a sealing rubber gasket 40, and the sealing grooves 11 used to accommodate the sealing rubber gasket 40 on the valve chamber cover 10 have different groove depths. For the structure in which the wheel shaft bearing cap 30 protrudes to the outside of the chamber surrounded by the valve chamber cover 10 and the cylinder head 20, the joint surface of the valve chamber cover 10 and the camshaft bearing cap 30 is not a plane. The structural shape and the distribution of the bolts 50 are analyzed and calculated for the pressing force of the sealing rubber pad 40 at the joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com