Tympanic-membrane type repeatedly openable optical fiber cold connector

A technology of tympanic membrane and optical fiber, which is applied in the field of connecting devices for optical fiber docking installation. Pollution and erosion troubles, improved success rate, uniform deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings.

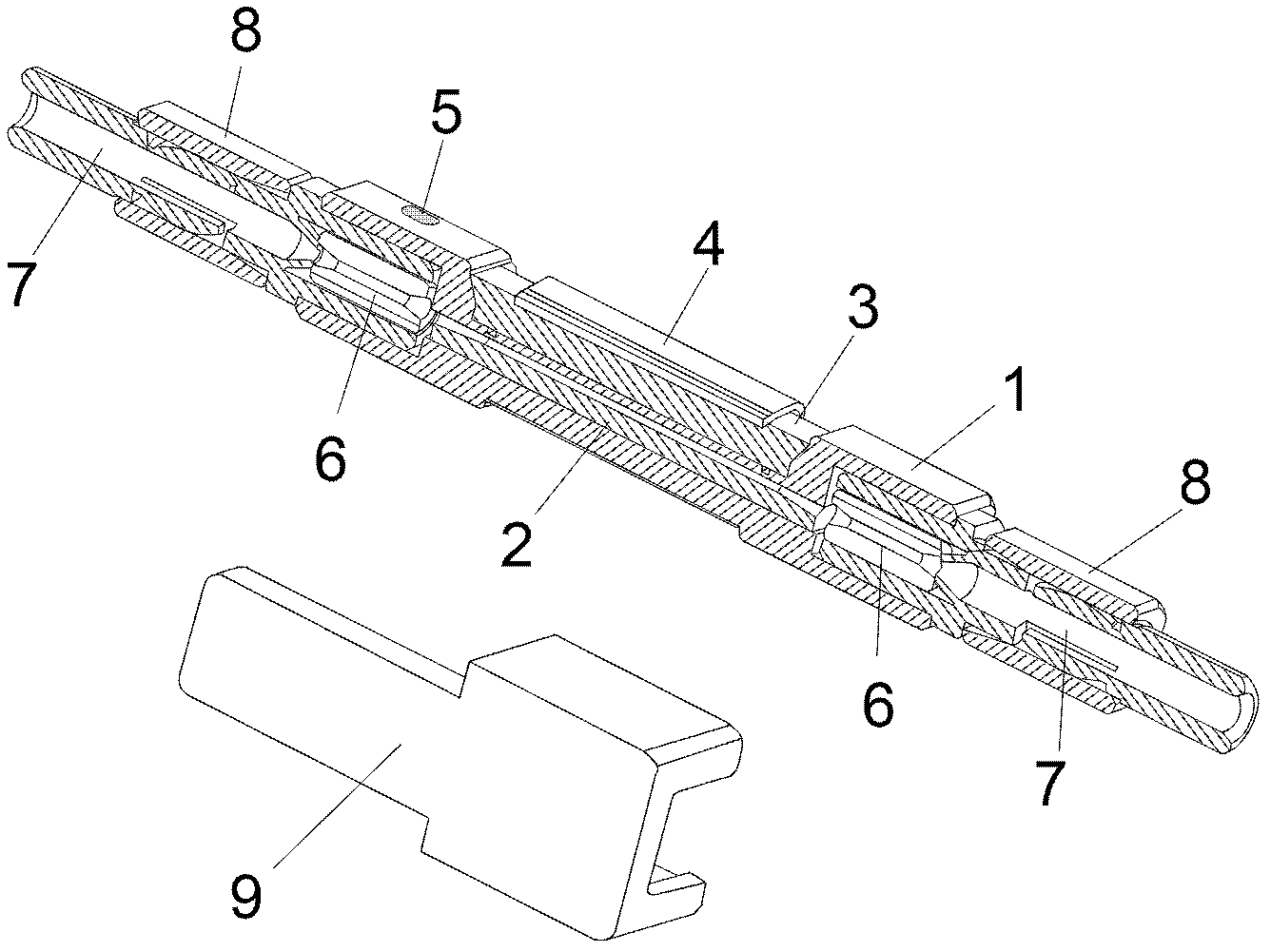

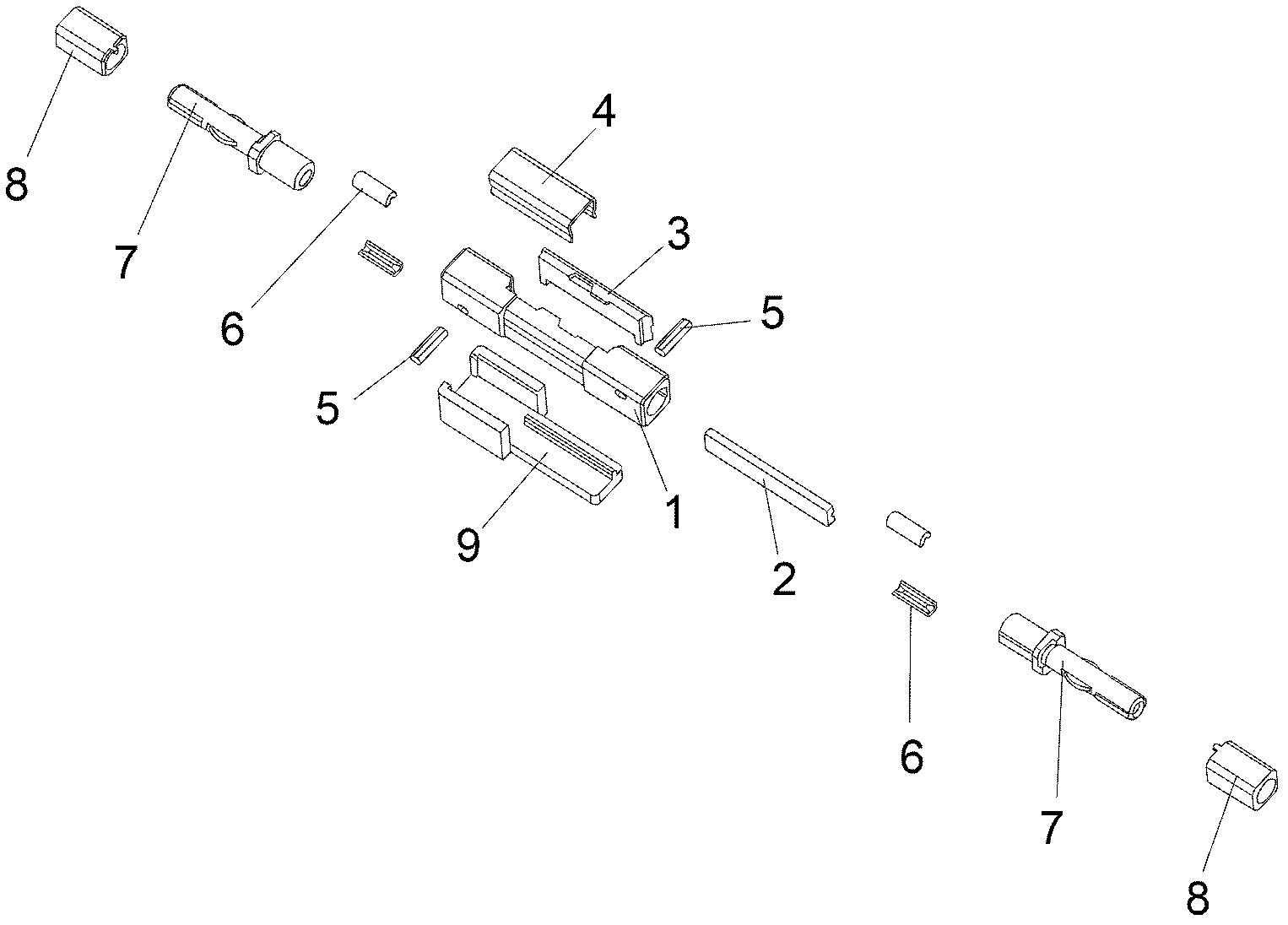

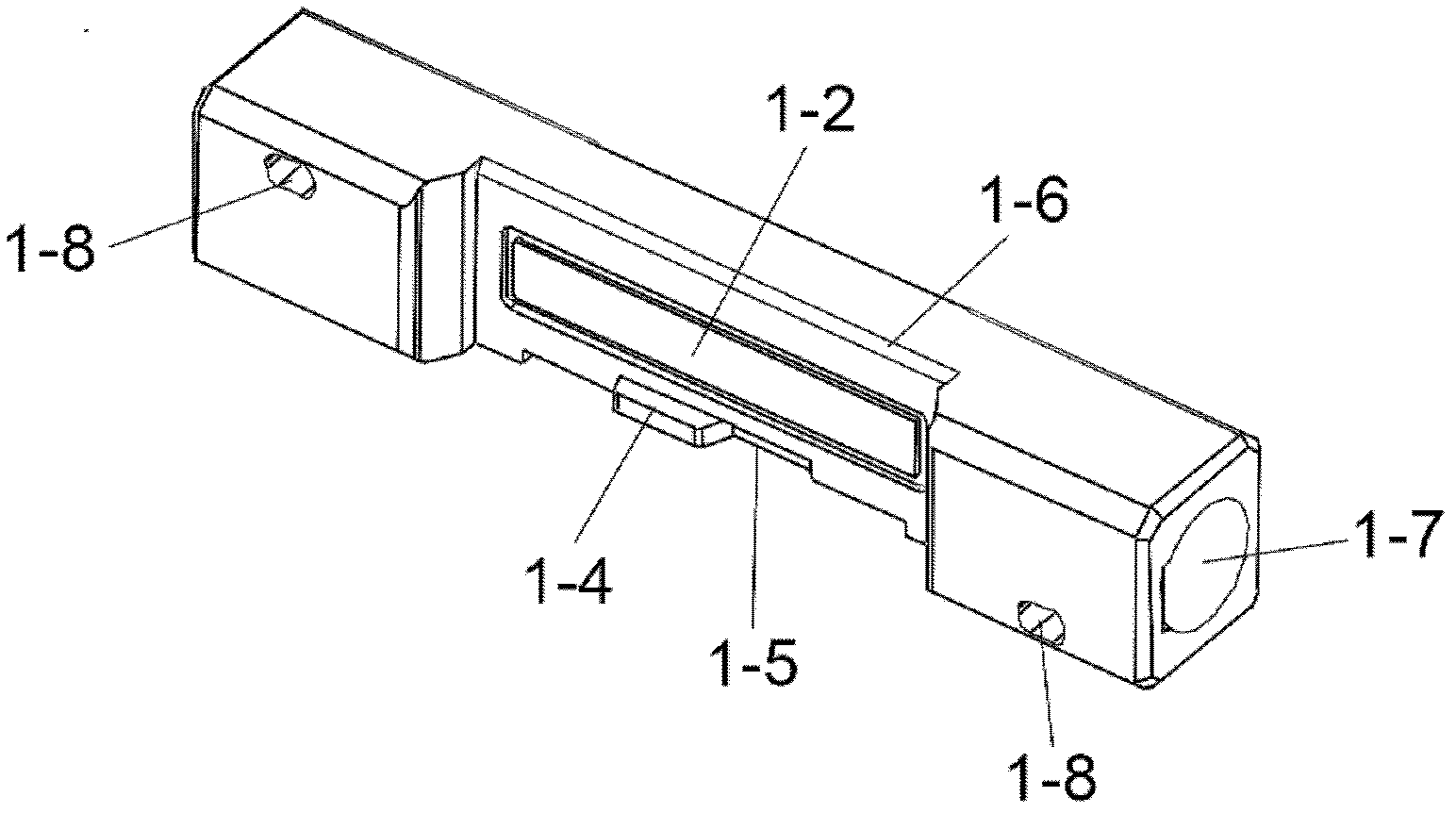

[0048] like figure 1 , 2 , 3, 4, 7, 8, 9, 10,

[0049] It includes a box body 1, a V-shaped block 2, a box cover 3, a spring clip 4, a latch 5, a wire block 6, a tail handle 7, a push tube 8 and an opening cover 9. The box body 1 is provided with a tympanic cavity 1- 1. A tympanic membrane 1-2 is set in the middle of the tympanic cavity 1-1, and there are floating ribs 1-3 around the tympanic membrane 1-2; the V-shaped block 2 is sealed in the tympanic cavity 1-1 of the box body 1, and the V-shaped block 2 is in The optical fiber through hole 2-3 is formed between the V-shaped groove 2-1 arranged on the opposite surface of the tympanic membrane 1-2 and the tympanic membrane 1-2; the box cover 3 is attached to the box body 1, and the spring clip 4 holds the box body 1 and the box body together. The cover 3 hugs together and drives the tympanic membrane 1-2 to compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com