Silk conveying mechanism and thread cutting device

A wire feeding and along-the-line technology, which is applied in the field of wire cutting machines, can solve the problems of inconsistent pressing force and low cutting precision of the wire cutting device, and achieve the effect of quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

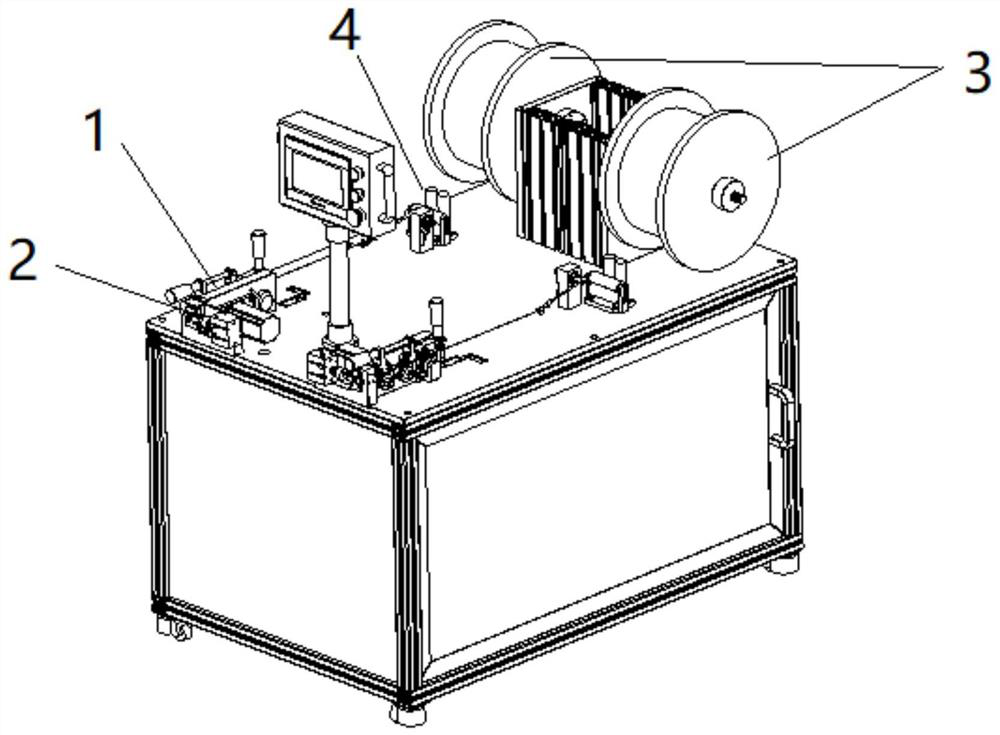

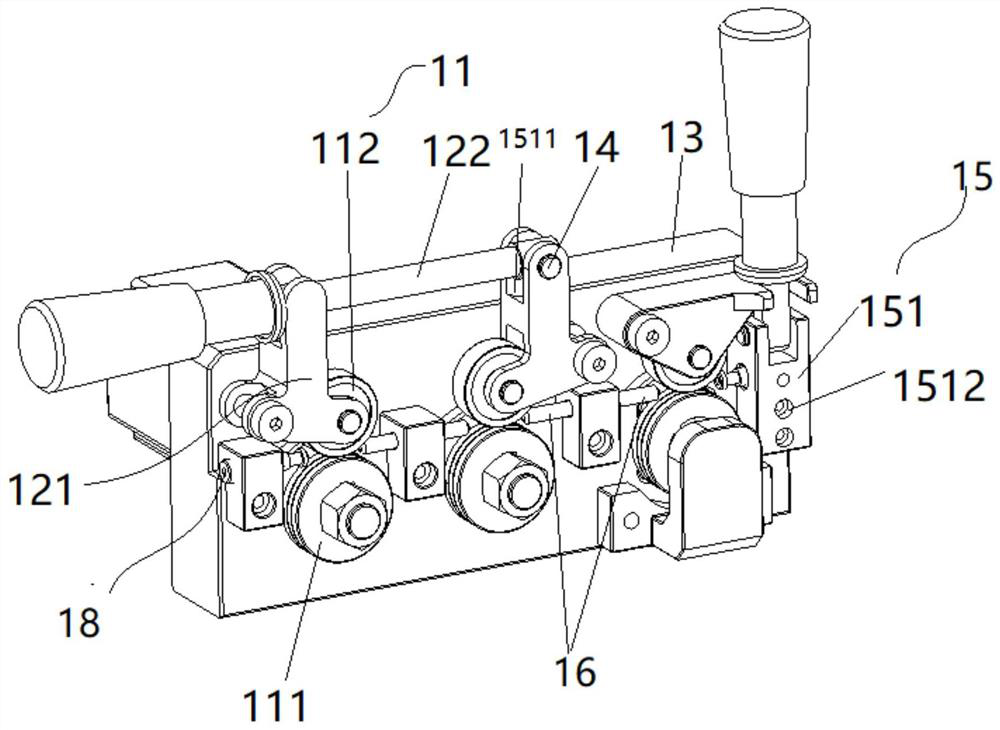

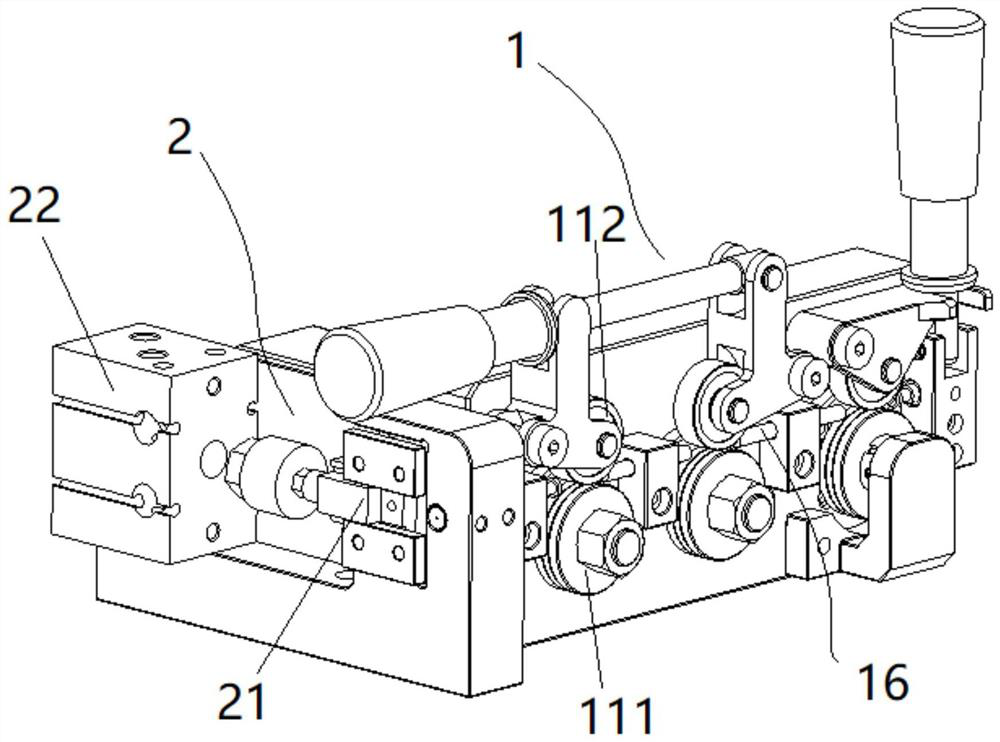

[0057] This embodiment provides a wire cutting device, such as figure 1 and figure 2 As shown, the thread cutting device includes a wire feeding mechanism 1 for conveying the wire and a thread cutting mechanism 2 for cutting the wire output from the output end of the wire feeding mechanism 1, wherein the thread cutting mechanism 2 is arranged on the wire feeding mechanism 1. At the outlet end 18 of the mechanism 1, the thread cutting mechanism 2 can be stably cut.

[0058] Specifically, see figure 2 and image 3 As shown, in the present embodiment, the above-mentioned thread cutting mechanism 2 includes a cutter 21 and a cutter driver 22 for driving the cutter 21 to move. The wire output from the wire outlet end 18 of the wire mechanism is cut. Specifically, the cutter driver can be driven by a cylinder or a motor.

[0059] In this embodiment, the above-mentioned wire feeding mechanism 1 includes a mounting base 13, at least two conveying assemblies 11 and at least one a...

Embodiment 2

[0079] This embodiment provides a wire cutting device, see figure 2 , compared with the thread cutting device provided in Embodiment 1, the difference is that the structure of the adjustment member 121 is different. In this embodiment 1, the longitudinal section of the adjustment member 121 is set to be an inverted T shape, and the level of the T shape is Two ends of the vertical part are respectively connected to the first rotating shaft 14 and the pressing member 112 , and the end of the vertical part is connected to the first driving member 122 .

Embodiment 3

[0081] This embodiment provides a wire cutting device, see figure 2 , image 3 and Figure 8 The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the support seat 151 in this embodiment can be directly installed on the above-mentioned installation seat 13, specifically, the support seat 151 can be provided with an installation hole 1512 , and arranged along the feeding direction of the wire, the above-mentioned limiting assembly 15 also includes fasteners, the support base 151 is installed on the support base 151 through fasteners, wherein the fasteners can pass through any one of the installation holes 1512, and then Fix the supporting base 151 on the mounting base 13, the mounting holes 1512 of this embodiment can be provided with at least two, such as three, four, and the specific number is arranged according to the actual situation. As the number increases, the supporting base The changeable position of 151 on the mounting base 13 will also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com