Drum membrane type optical fiber splicer capable of being repeatedly opened to be used

A technology of optical fiber connectors and tympanic membranes, which is applied in the field of optical fiber connectors, can solve the problems of easily scratched V-shaped blocks, affect light transmission, and cannot be sealed, so as to avoid pollution and erosion, improve centering accuracy, and prevent optical fiber from being crushed. The effect of taking off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings.

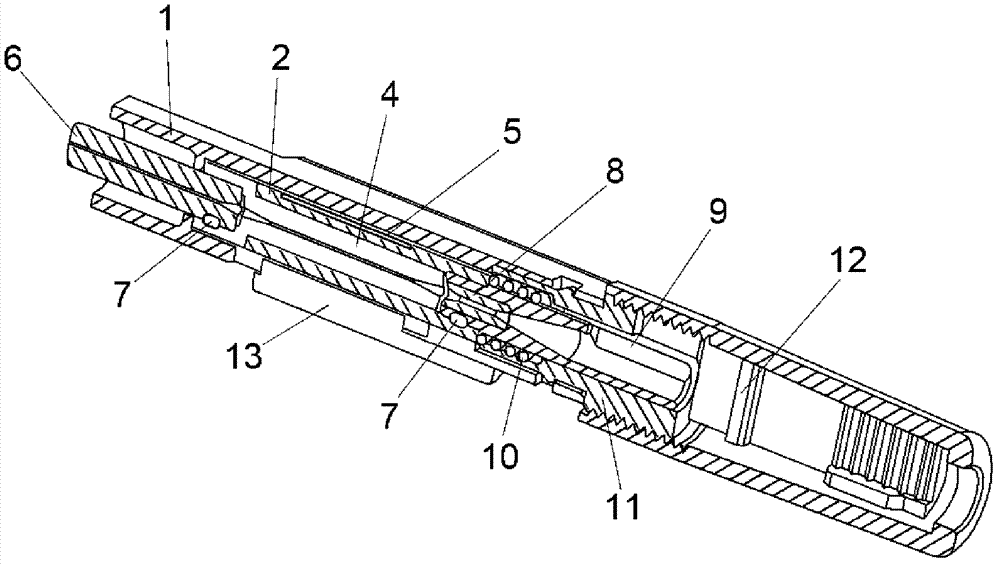

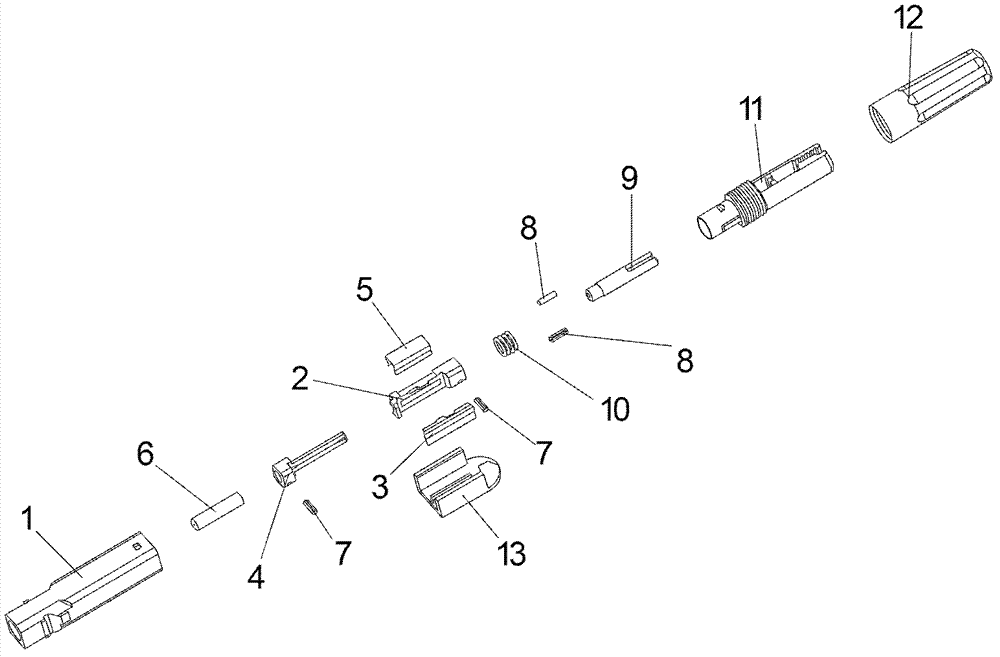

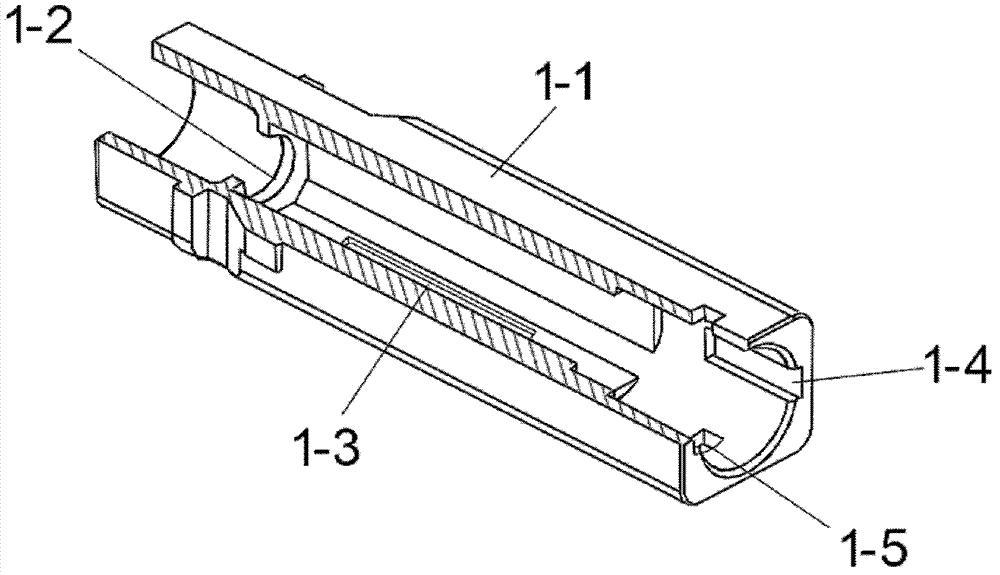

[0044] like figure 1 , 2 , 3, 4, 6, 9, 11, 12, 13,

[0045] Including ferrule assembly 14, box assembly 15, housing assembly 16, spring 10 and opening cover 13, the ferrule assembly 14 includes ferrule 6, latch 7, V-shaped groove body 4, V-shaped The front end of the tank body 4 is provided with a front connection cavity 4-4, and the front connection cavity 4-4 is connected with the ferrule 6 through a latch 7; the box assembly 15 includes a box body 2, a box cover 3, a spring clip 5, The plug 7, the wire block 8 and the wire body 9 are provided with a tympanic cavity 2-1 in the box body 2, and a tympanic membrane 2-2 is arranged in the middle of the tympanic cavity 2-1, and there are floating ribs 2-2 around the tympanic membrane 2-2. 3. The V-shaped groove 4-1 in the ferrule assembly 14 is partially inserted into the tympanic cavity 2-1, and the V-shaped groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com