Cu2O ultra-fine nano-particles and self-assembly nanospheres as well as preparation method thereof

A technology of ultra-fine nano and nano microspheres, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of environmental hazards, inability to prepare, and inability to solve the problem of agglomeration, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

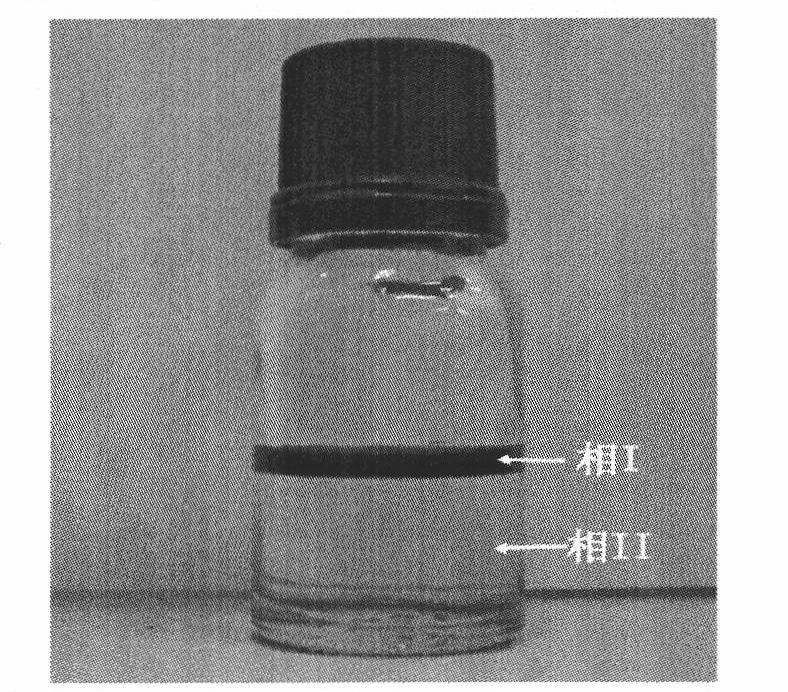

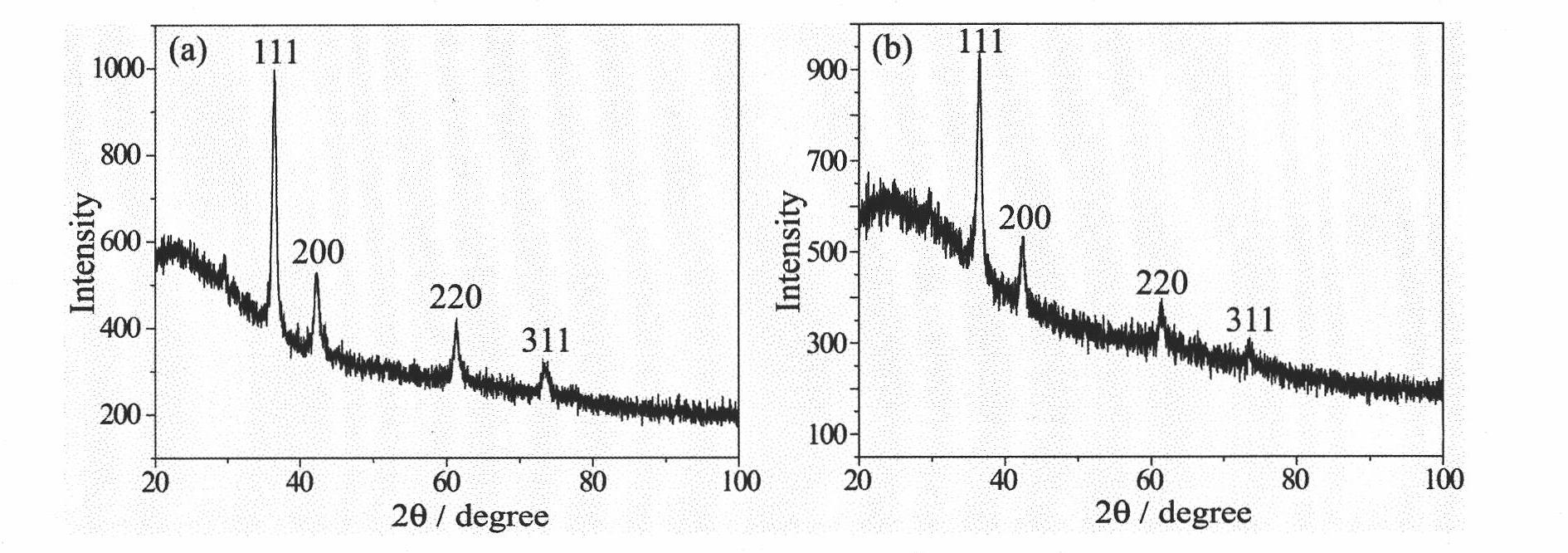

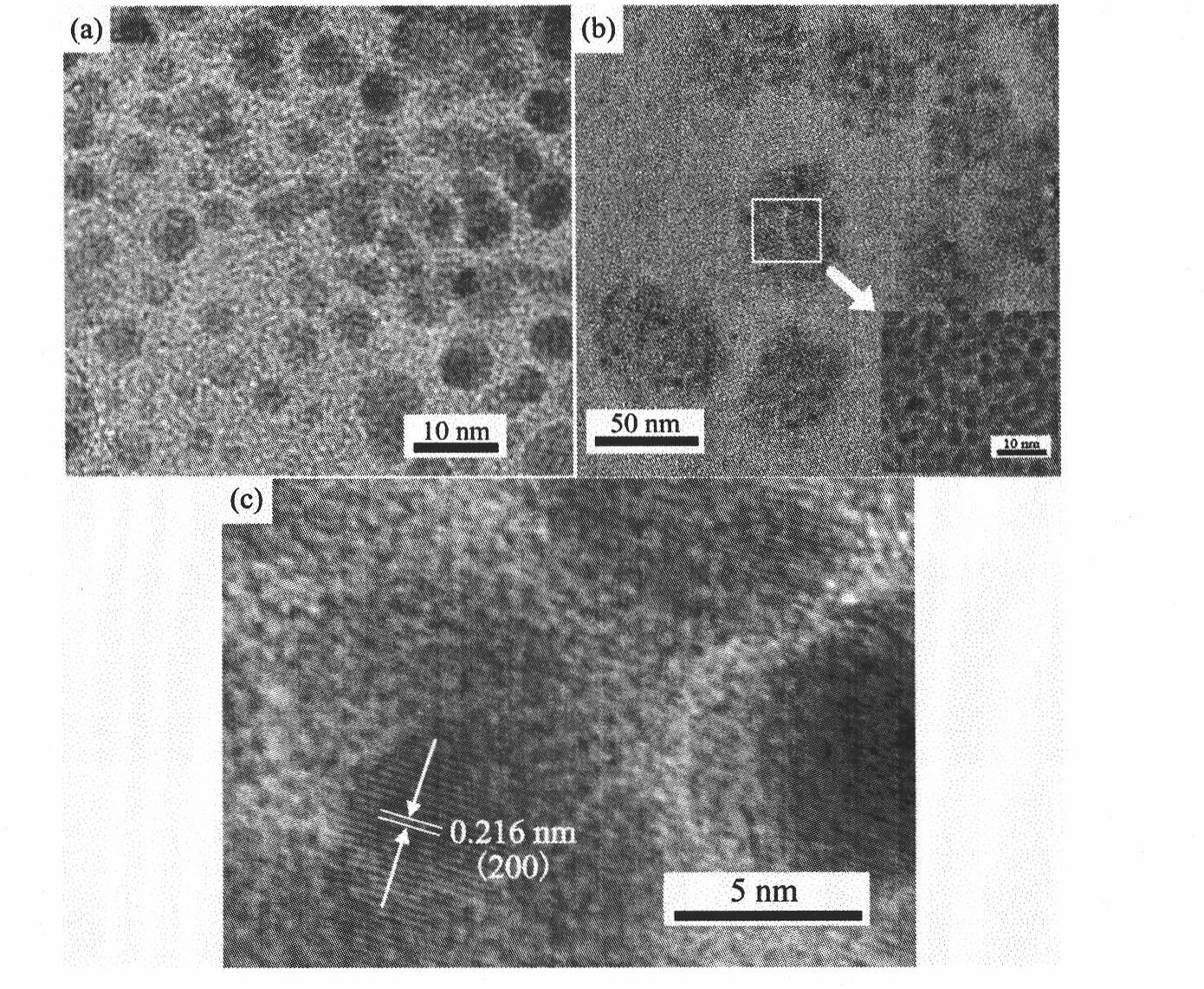

[0041] Example 1: 0.175g of PVP was dispersed in 8mL of ethylene glycol in which NaOH was dissolved (the pH of the ethylene glycol solution was 12.7) to prepare a PVP solution. Dissolve 1.5 g of ascorbic acid in 12 mL of ethylene glycol in which NaOH is dissolved (the pH value of this NaOH / ethylene glycol solution is also 12.7) to prepare an ascorbic acid solution. Add 16mL of ethylene glycol, 0.4g of copper chloride dihydrate, and 1.5mL of oleic acid to the container in turn, and stir vigorously for 40min. Then add the PVP solution prepared above into this container, slowly raise the temperature of the mixed liquid in the container to 70°C, keep it warm for 30min, and wait until the mixed liquid in the container is divided into two phases (see figure 1 ). Pour the previously prepared ascorbic acid solution into the container at one time. Raise the temperature to 80°C and keep it warm for 30 minutes, the reactant in the container gradually turns green. Add 10 mL of ethanol ...

Embodiment 2

[0042] Example 2: 0.175g of PVP was dispersed in 8mL of ethylene glycol in which a certain amount of NaOH was dissolved (the pH of the ethylene glycol solution was 12.7) to prepare a PVP solution. Dissolve 1.5 g of ascorbic acid in 12 mL of ethylene glycol in which NaOH is dissolved (the pH value of this NaOH / ethylene glycol solution is also 12.7) to prepare an ascorbic acid solution. Add 16mL of ethylene glycol, 0.4g of copper chloride dihydrate, and 1.5mL of oleic acid to the container in turn, and stir vigorously for 40min. Then add the PVP solution prepared above into this container, slowly raise the temperature of the mixed liquid in the container to 70°C, keep it warm for 30min, and wait until the mixed liquid in the container is divided into two phases (see figure 1 ). Pour the previously prepared ascorbic acid solution into the container at one time. Raise the temperature to 80°C and keep it warm for 30min. The reactant in the container gradually turns green. Continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com