Connection method for carbon steel and zirconium oxide ceramic and connecting piece manufactured thereby

A zirconia ceramic and connection method technology, which is applied in welding/welding/cutting items, manufacturing tools, welding equipment, etc., can solve the problems of long holding time, difficult joints, time-consuming connection, etc., and achieves low vacuum and large equipment vacuum. The effect of shear strength and short holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

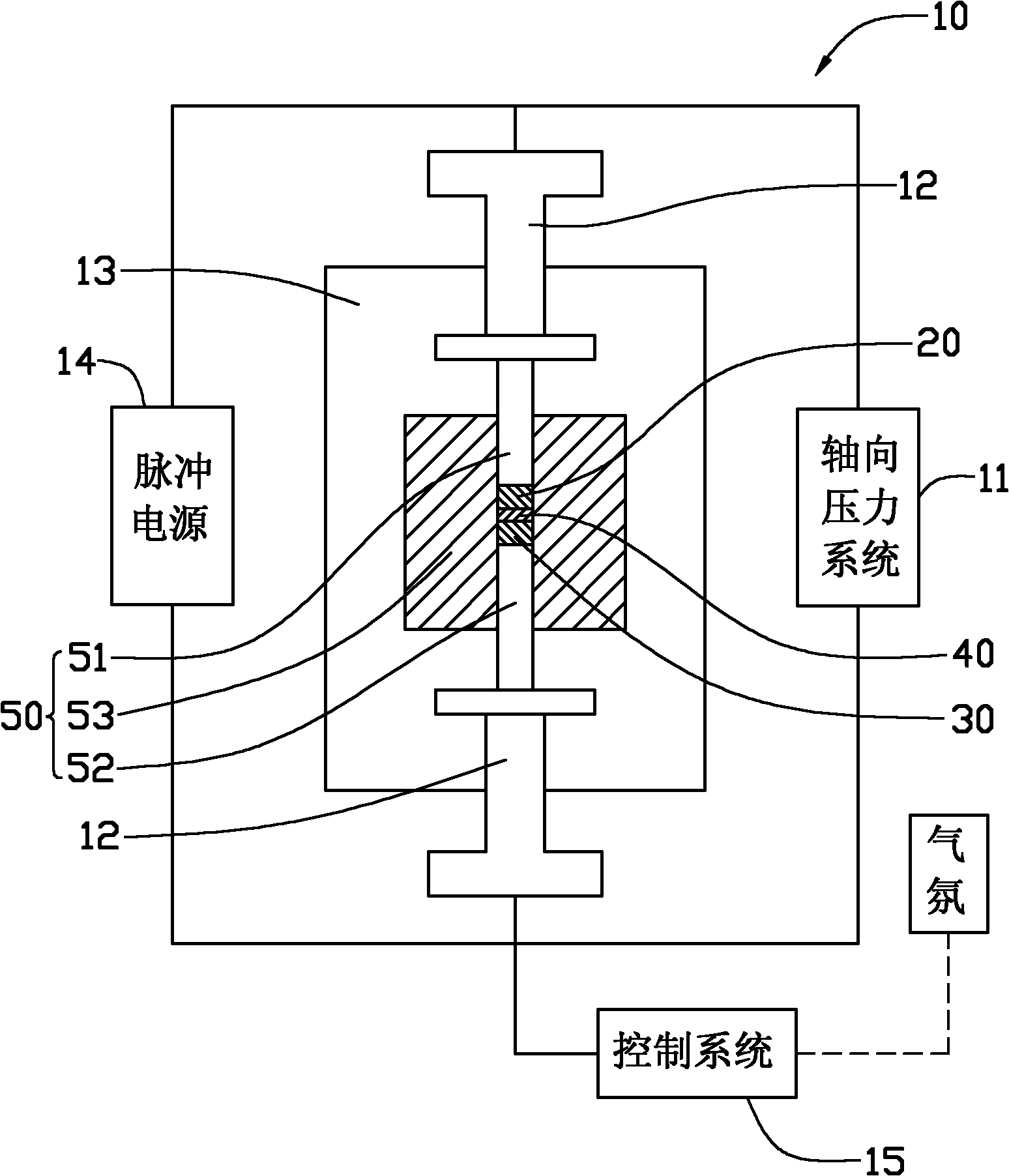

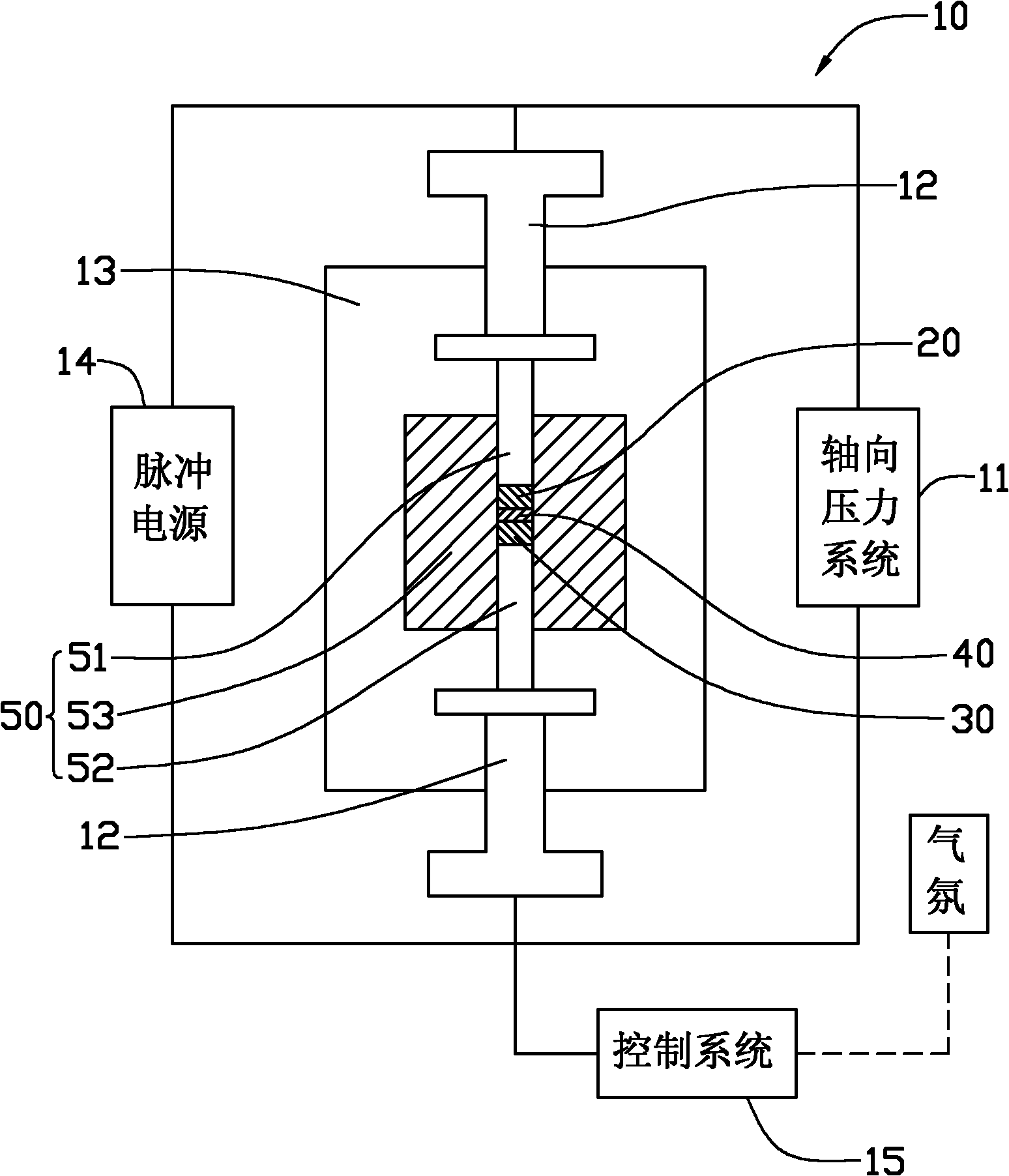

[0036] see figure 1 , the method for connecting carbon steel and zirconia ceramics in a preferred embodiment of the present invention is mainly accomplished by using a discharge plasma sintering device 10, and the method mainly includes the following steps:

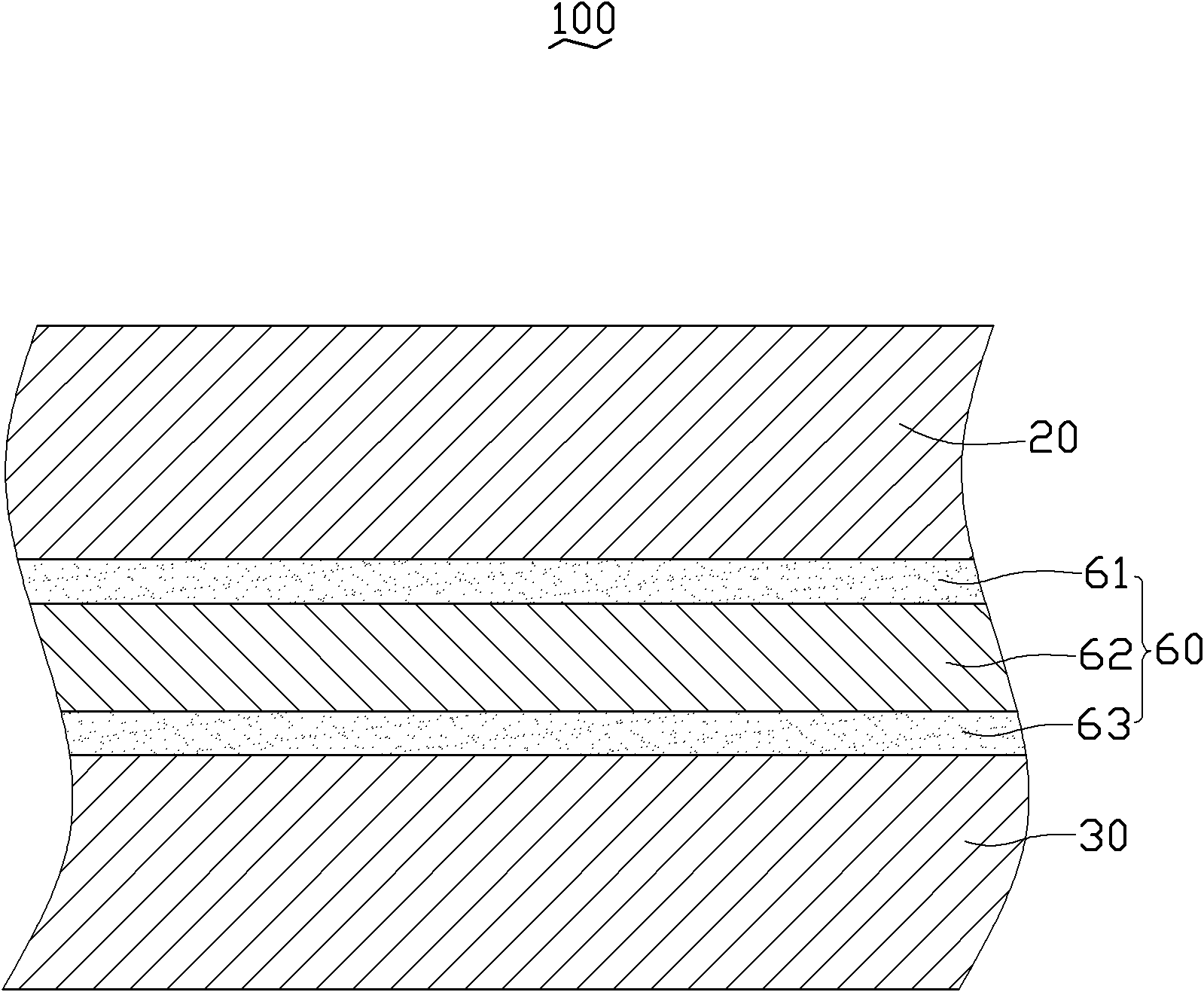

[0037] (1) Provide a carbon steel part 20 to be connected, a zirconia ceramic part 30 and an active intermediate layer 40 . The active intermediate layer 40 is titanium foil with a thickness of approximately 0.1-0.5 mm, preferably 0.2-0.3 mm.

[0038] (2) Grinding and cleaning the active intermediate layer 40 and the surfaces to be connected of the carbon steel part 20 and the zirconia ceramic part 30, and drying them. In this embodiment, 400-800 mesh metallographic sandpaper can be used to polish the active intermediate layer 40, the carbon steel part 20 and the zirconia ceramic part 30; then use dilute hydrochloric acid or dilute sulfuric acid solution to clean; rinse with water after acid cleaning and blow dry . Her...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com