Fine and smooth tilapia mossambica bone and fish sauce and preparation method thereof

A technology of tilapia and bone meat paste, which is applied in the direction of food preparation, application, food science, etc., can solve the problems of bone meal products such as low nutrient utilization rate of raw materials, damage of heat-sensitive components, and impact on product quality, so as to broaden the scope of comprehensive utilization, The effect of shortening the holding time and improving the softening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Wash the fish steaks in clean water to remove the blood stains and residual viscera on the vertebral membranes of the fish steaks, remove the darker ventral, dorsal and caudal fins, and chop the rest for later use. Mix the fish bone with 6% acetic acid solution at a mass ratio of 2:1, soak the material in the acid solution, and cook in a high-pressure cooker for 45 minutes at 126°C. After cooking, the feed liquid is separated, the solid material is roughly crushed by a meat grinder, and then the crushed material is remixed with the cooking liquid, and 50% of the total mass of the feed liquid is added with water and stirred evenly. Grind the material in a colloid mill, adjust the gap between the inner and outer mills to 20 μm, and grind it circularly for 5 minutes, take it out, carry out vacuum degassing treatment, and then use M-110EH high-pressure micro-jet nano-homogenizer for secondary crushing treatment. 120MPa. After treatment, the average particle size of the slu...

Embodiment 2

[0035] Wash the fish steaks in clean water to remove the blood stains and residual viscera on the vertebral membranes of the fish steaks, remove the darker ventral, dorsal and caudal fins, and chop the rest for later use. The fish bone and the acid solution with a mass concentration of 9% were uniformly mixed at a mass ratio of material to liquid of 2:1, and the acid solution was immersed in the material, and placed in a high-pressure cooker for 90 minutes at 126° C. After cooking, the feed liquid is separated, the solid material is roughly crushed by a meat grinder, and then the crushed material is remixed with the cooking liquid, and 50% of the total mass of the feed liquid is added with water and stirred evenly. Grind the material in a colloid mill, adjust the gap between the inner and outer mills to 20 μm, and grind it circularly for 5 minutes, take it out, carry out vacuum degassing treatment, and then use M-110EH high-pressure micro-jet nano-homogenizer for secondary crus...

Embodiment 3

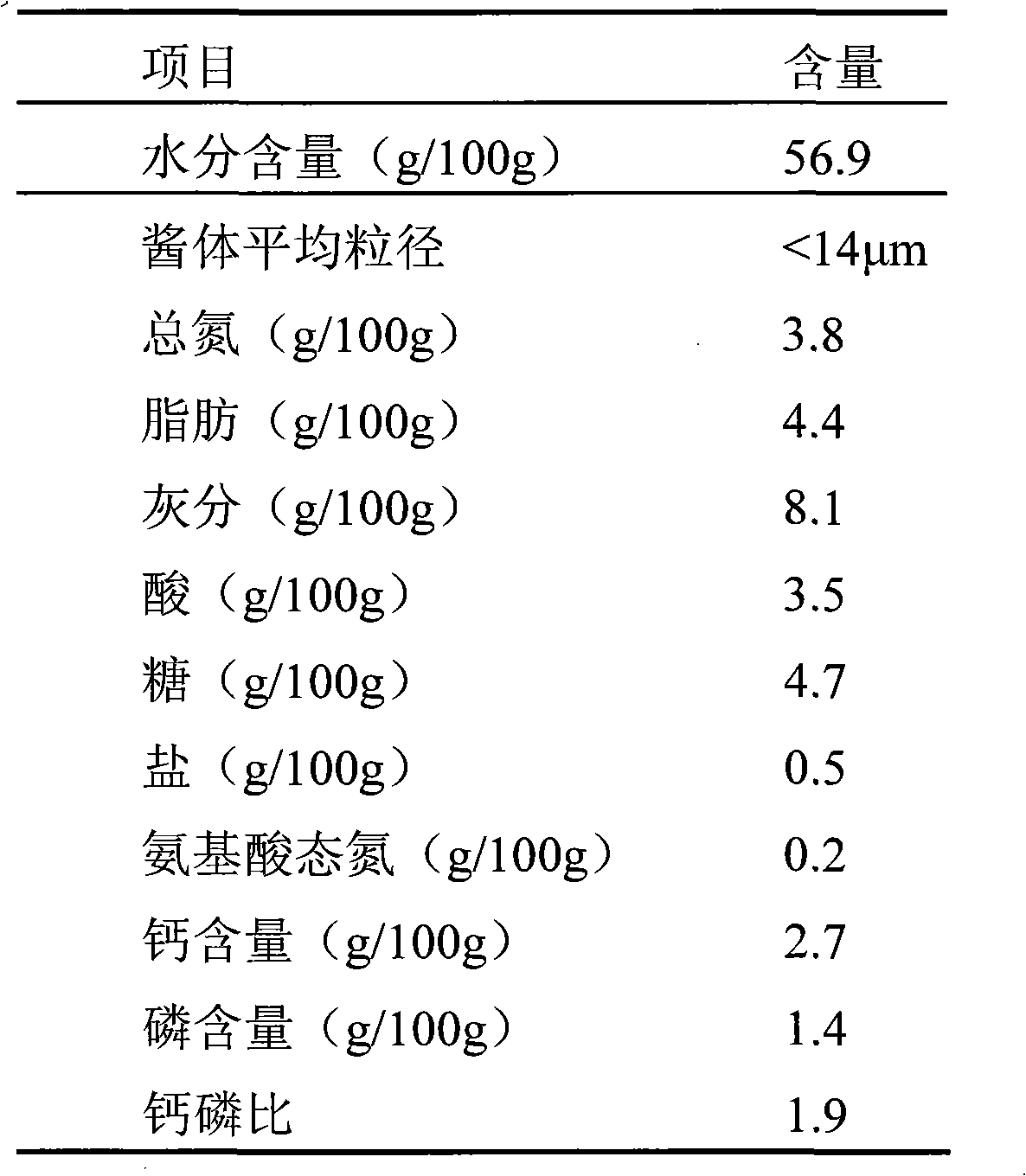

[0037] Evaporate and concentrate the tilapia bone meat slurry after the secondary pulverization to make its moisture content reach 60.3%. Add 5% granulated sugar and 0.5% salt according to the mass of the sauce after concentration and stir evenly. After vacuum packaging, it is sterilized by boiling water at 100°C for 30 minutes, and the tilapia spread product can be prepared. Pale yellow, shiny surface. No earthy smell, moderate acetic acid smell. It is sweet and sour, moderately salty, has the unique taste of fish, and the fishy smell is not obvious. The average particle size of the sauce body is less than 14 μm, fine and smooth, without obvious graininess, and it melts in the mouth. The spread has good spreadability. The sauce body is easy to spread evenly and adheres completely to the food without flowing after application. The acidity of the sauce is 3%, and the product can be stored at room temperature after sterilization. The ratio of calcium to phosphorus in the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com