Catalyst used for ozone catalyzing and oxidizing treatment of hard-to-degrade waste and preparation method and application thereof

A catalyst and catalyst carrier technology, applied in catalyst activation/preparation, oxidized water/sewage treatment, metal/metal oxide/metal hydroxide catalyst, etc., can solve the restriction on the promotion and utilization of ozone catalytic oxidation technology and product recycling Difficulties, cumbersome preparation methods, etc., to achieve the effects of improving the reaction rate and the utilization rate of ozone, easy large-scale preparation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0061] (1) Put 100g of catalyst carrier-activated alumina pellets into 0.01mol / L NaOH solution to wash for 5 minutes, then wash with pure water until neutral, and dry at 100°C for later use;

[0062] (2) Preparation of precursor solution:

[0063] The active components of the catalyst (based on the total weight of metal elements Fe, Mn and Cu) account for 8% of the total weight of the catalyst.

[0064] Weigh 28.86g ferric nitrate nonahydrate, 8.91g manganese acetate tetrahydrate, and 7.55g copper nitrate trihydrate and dissolve them in 150ml water, put the catalyst carrier prepared in step (1) into it, add NaOH to adjust the pH of the impregnation solution to 6.0, then put the carrier pellets and impregnation solution into the Erlenmeyer flask and then put it in the shaker, impregnate at 50°C for 20h, and rotate at 100rpm;

[0065] (3) After soaking, put the precursor solution and carrier pellets together into the reactor for hydrothermal reaction, the reaction condition is ...

Embodiment 2

[0074] Preparation examples of heterogeneous ozone catalysts for ozone catalytic oxidation treatment of refractory wastewater:

[0075] (1) Put 100g of catalyst carrier-activated alumina pellets into 0.01mol / L NaOH solution to wash for 3 minutes, then wash with pure water until neutral, and dry at 120°C for later use;

[0076] (2) Preparation of precursor solution:

[0077] The active components of the catalyst (based on the total weight of metal elements Fe, Mn and Cu) account for 15% of the total weight of the catalyst.

[0078] Take by weighing 43.28g ferric nitrate nonahydrate, 13.37g manganese acetate tetrahydrate, 22.65g copper nitrate trihydrate and dissolve in 150ml water, put the catalyst carrier prepared in step (1) into it, add Na 2 CO 3 Adjust the pH of the impregnating solution to 5.5, then put the carrier pellets and the impregnating solution in a shaker, and impregnate at 50°C for 8 hours at a speed of 150rpm;

[0079] (3) After soaking, put the precursor sol...

Embodiment 3

[0088] In addition to adjusting the amount of raw materials added, the catalyst active component (based on the total weight of metal elements Fe, Mn and Cu) accounts for 10% of the total weight of the catalyst, and n(Fe):n(Mn):n(Cu) is 2:1 : 1, other methods and conditions are identical with embodiment 1.

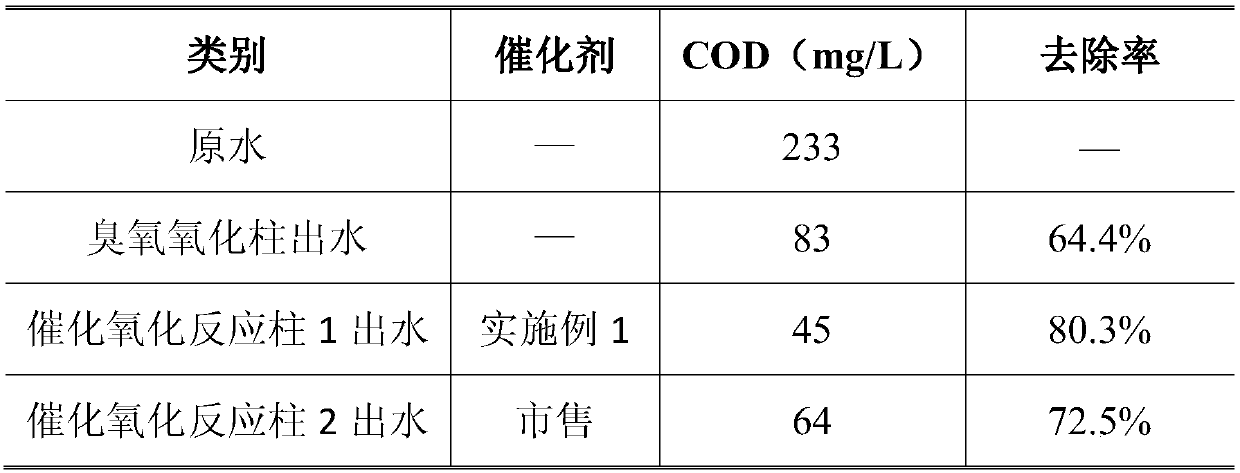

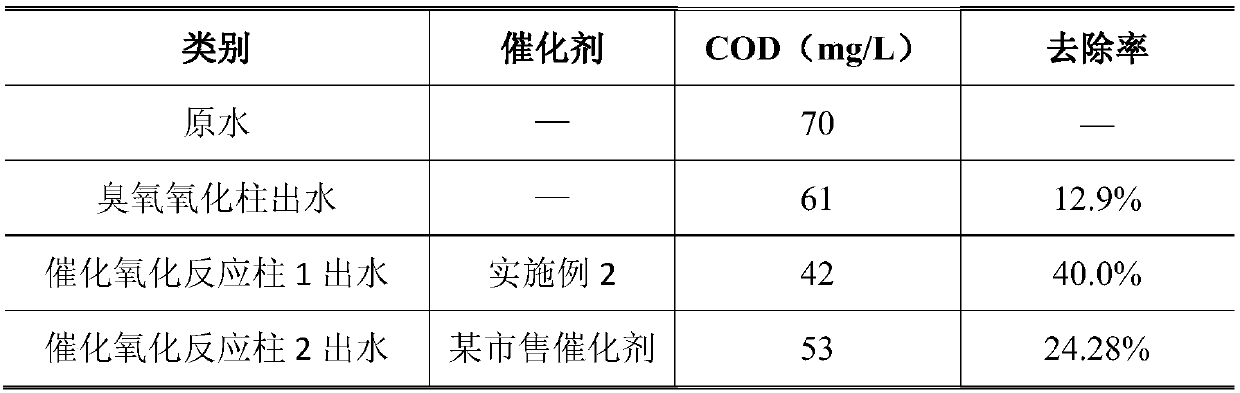

[0089] Catalyst catalytic activity test

[0090] The salt chemical tail water with COD about 95mg / L, pH 6.87, and salt content about 1058μs / cm was used as the experimental object. Carry out the small-scale experiment of dynamic continuous operation of ozone catalytic oxidation, add the catalyst of Example 3 into the catalytic oxidation reaction column 1, and add a commercially available catalyst into the catalytic oxidation reaction column 2. The reaction conditions of the two reaction columns are the same.

[0091] At room temperature, after running continuously for 3 hours, take the effluent from each reaction column to measure the chemical oxygen demand (COD) according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com