Hot-processing production system for titanium and titanium alloy seamless tube, product prepared on basis of system and manufacture method for product

A production system and production method technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of long heating time, low thermal conductivity of titanium and titanium alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

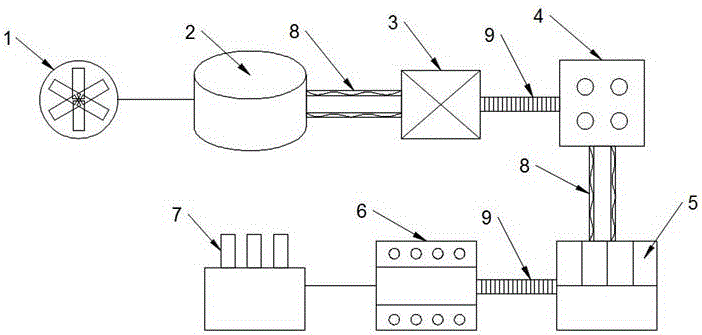

[0054] Thermal processing production system of titanium and titanium alloy seamless pipes, including the following equipment:

[0055] Centering machine 1, which is used to process centering holes at both ends of titanium and titanium alloy tube blanks for piercing and rolling;

[0056] Annular furnace 2, which is used for heating titanium and titanium alloy tube blanks;

[0057] High-precision in-machine centering bacterial piercing unit 3, which is used to perforate and roll tube blanks to obtain capillary tubes, including high-precision in-machine centering vertical fungus-type piercing machines, high-precision in-machine centering horizontal fungus-type piercing machines and An automatic control machine for adjusting the clamping force and opening degree of the centering roll in the rolling state; the material of the rolls of the high-precision machine-centered vertical mushroom-type piercer and the high-precision machine-centered horizontal mushroom-type piercer is 60CrMn...

Embodiment 2

[0077] Titanium and titanium alloy seamless pipes produced by the production system of titanium and titanium alloy seamless pipes described in Example 1, including grades TA1, TA2, TA3, TA4, TA5, TA6, TA7, TA8, TA8-1 , TA9, TA9-1, TA10, TA13, TA15, TA18, TC1, TC2, TC3, TC4, TC10 seamless pipe, the diameter of the seamless pipe is 73-325mm, the wall thickness is 5.5-25.0mm, the length The maximum is 135000mm or 13.5 meters.

[0078] The microstructure and chemical composition of each brand of titanium and titanium alloys are different. In this embodiment, under the production system provided in Example 1, titanium and titanium alloy seamless pipes of various grades and specifications can be obtained to meet the needs of the market. need.

Embodiment 3

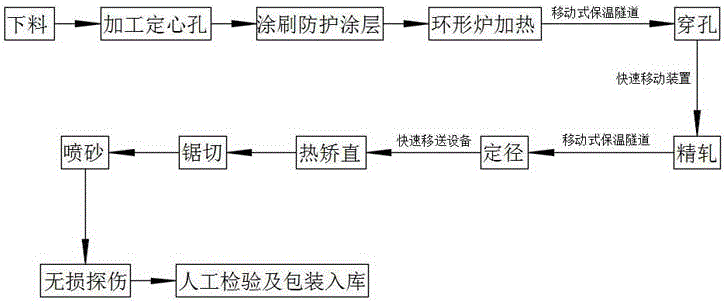

[0080] The thermal processing production method of the titanium and titanium alloy seamless pipe described in the above-mentioned embodiment 2 comprises the following operations:

[0081] 1) Cutting: Cut the titanium and titanium alloy blanks according to the length required by the production, and process the cut blanks to the corresponding outer diameter according to the production requirements, and at the same time ensure that the surface roughness after processing is Ra≤3.2μm. The material is completed to obtain a qualified titanium alloy tube blank;

[0082] 2) Centering hole: Use the centering machine 1 to process the centering hole on both ends of the tube blank;

[0083] 3) Apply protective coating: apply protective coating to the surface of the tube blank;

[0084] 4) Heating: put the tube billet in the ring furnace 2 for heating, heat and keep it in a micro-oxidizing atmosphere, and the furnace chamber is slightly positive pressure; among them, the average heating te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com