Copolyester with low melting point and synthesis method thereof

A technology of copolyester and polyethylene glycol, which is applied in the field of low melting point copolyester and its synthesis, can solve the problems of serious side reactions and unstable product performance, and achieves reduction of production cost, serious side reactions, and molecular weight and low molecular weight. The effect of uniform distribution of functional groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] The semi-continuous polymerization process is adopted, and the test device is a 50kg / batch semi-continuous small-scale polymerization device, which is composed of a slurry tank, an esterification tank 1, an esterification tank 2, a polycondensation tank, and a vacuum system.

[0116] Step 1: Prepare slurry

[0117] Put 33.75 kilograms of PTA, 11.25 kilograms of IPA, 21.5 kilograms of EG and 5 grams of phosphoric acid into the slurry kettle, and stir well. The molar ratio of PTA:IPA in the slurry is 75:25; the acid-alcohol molar ratio of the slurry is 1:1.28; the added amount of the stabilizer is 100ppm.

[0118] The second step: esterification 1 reaction

[0119] Add the slurry in batches to the esterification tank with half the amount of the previous batch of esterification liquid left to carry out the esterification reaction. The reaction is carried out under normal pressure, and the temperature of the material is controlled between 230 and 255 ° C. After 2 hours of ...

Embodiment 2

[0131] The semi-continuous polymerization process is adopted, and the test device is a 50kg / batch semi-continuous small-scale polymerization device, which is composed of a slurry tank, an esterification tank 1, an esterification tank 2, a polycondensation tank, and a vacuum system.

[0132] Step 1: Prepare slurry

[0133] Put 38.92 kilograms of PTA, 6.08 kilograms of IPA, 22.6 kilograms of EG and 5 grams of phosphoric acid into the slurry tank, fully and evenly. The molar ratio of the slurry PTA:IPA is 86.5:13.5; the acid-alcohol molar ratio of the slurry is 1:1.345; the added amount of the stabilizer is 100ppm.

[0134] The second step: esterification 1 reaction

[0135] Add the slurry in batches to the esterification tank with half the amount of esterification liquid left in the previous batch to carry out the esterification reaction. The reaction is carried out under normal pressure, and the temperature of the material is controlled between 250 and 260 ° C. After 2 hours o...

Embodiment 3

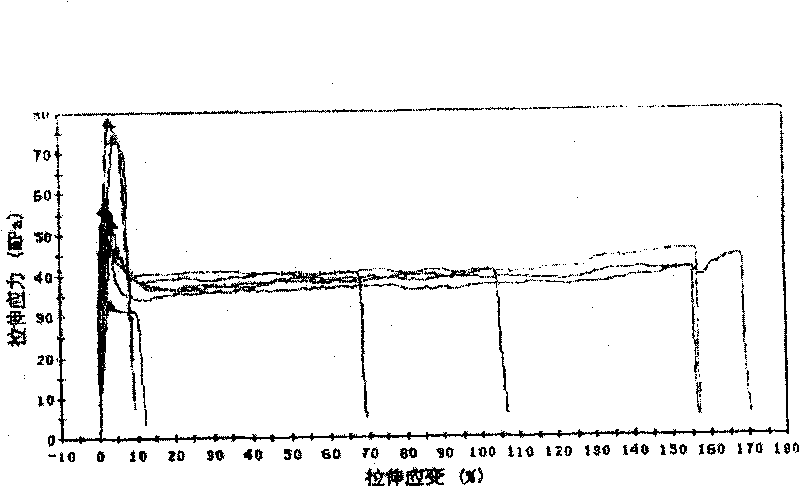

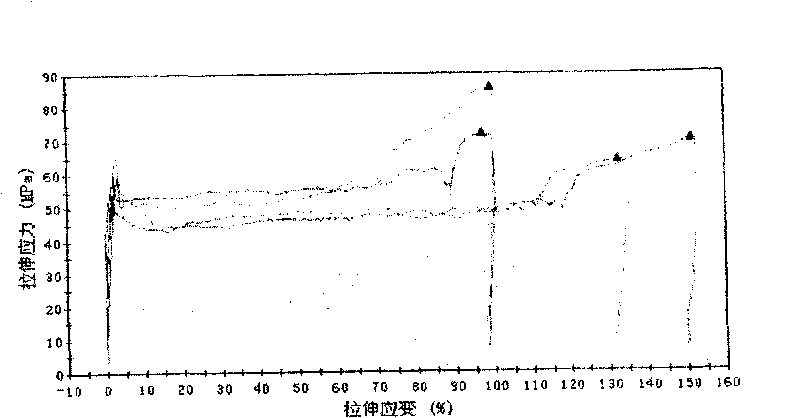

[0151] Sample Preparation

[0152] The A1 sample is the novel polyester produced by the formula and method provided in embodiment two.

[0153] A2 sample is the polyester produced according to the method provided in Example 2 without adding DEG.

[0154] A3 sample is 30.15 kilograms of PTA, 14.85 kilograms of IPA (the molar ratio of PTA:IPA is 67:33), without adding DEG, the polyester produced according to the method provided in Example 2.

[0155] The product qualities of the three samples are shown in the table below.

[0156] Table 4

[0157]

Sample serial number

(dl / g)

Melting point (DSC)

℃

℃

Color value

A1

0.73

none

175-200

L85a-0.1b4.0

A2

0.75

213.5

228

L87a-0.2b3.5

[0158]

Sample serial number

(dl / g)

Melting point (DSC)

℃

Melting poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com