Solid-liquid reaction still beneficial for interrupting reaction process

A technology of solid-liquid reaction and reaction process, which is applied in chemical/physical/physical-chemical fixed reactors, grain processing, etc. It can solve the problem that the reaction process is difficult to interrupt, the reaction process cannot be interrupted, and the contact between the liquid reactant and the solid reactant is not enough. Sufficient and other issues to achieve the effect of increasing the contact area and increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

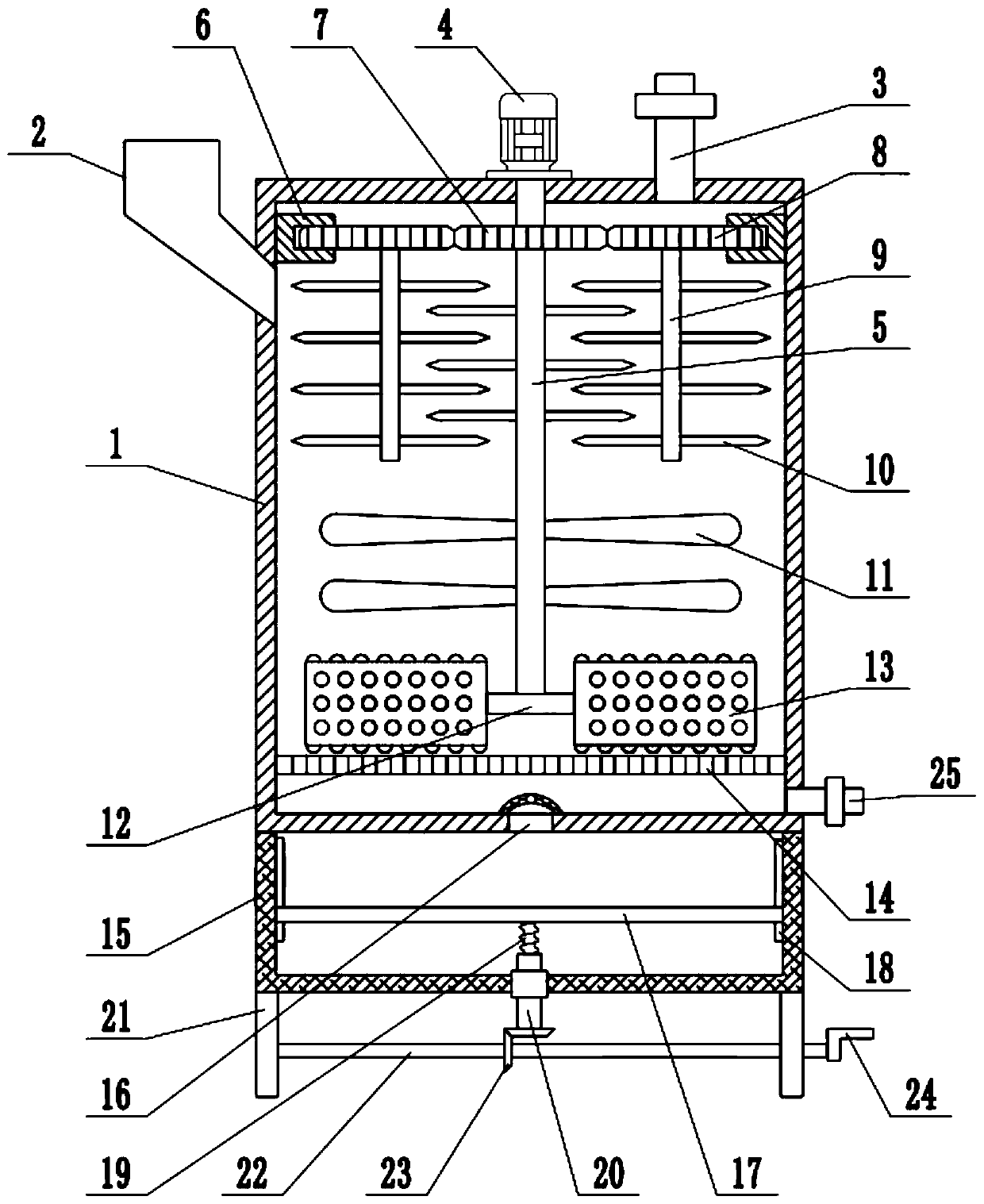

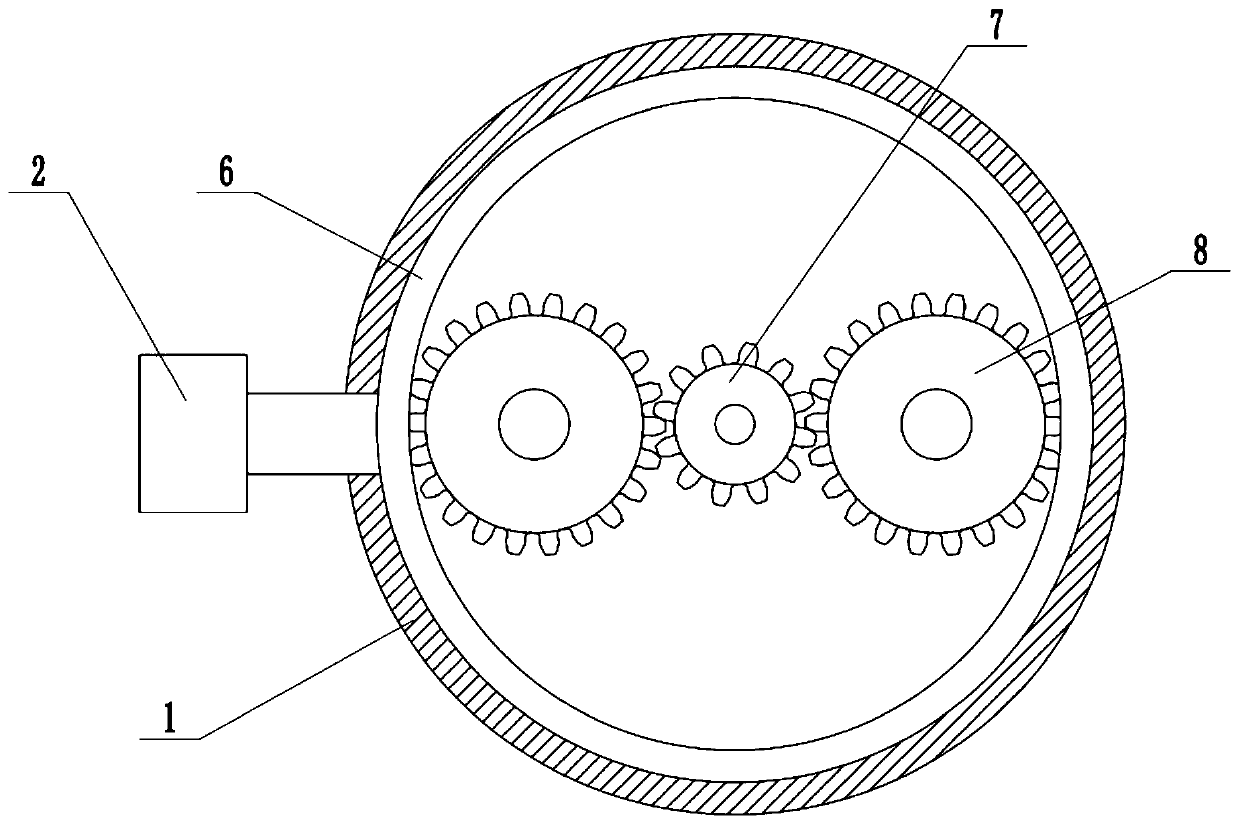

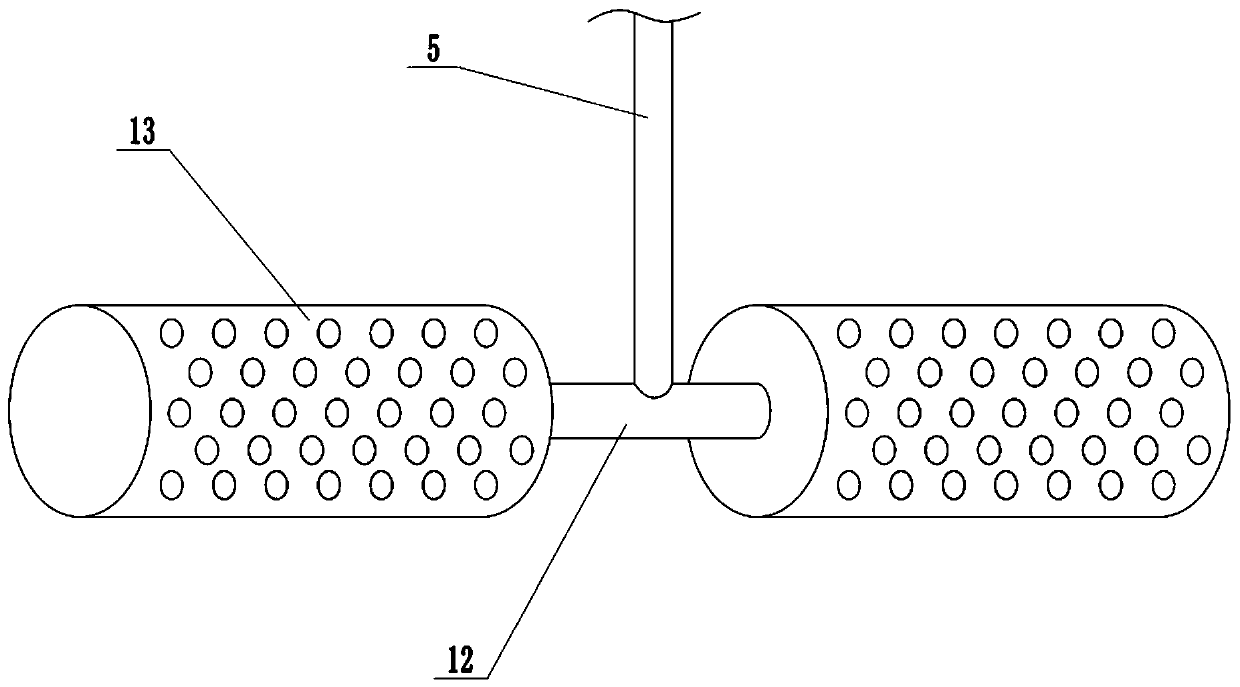

[0021] see Figure 1-3 , in the embodiment of the present invention, a kind of solid-liquid reaction kettle that is convenient to interrupt reaction process, comprises kettle body 1, motor 4, driving shaft 5 and sieve plate 14, and feed port 2 is installed on the side of kettle body 1, and on the feed port The sealing cover is detachably installed, and the solid reactant is poured into the kettle body 1 through the feeding port 2, and the liquid inlet pipe 3 is installed on the top of the kettle body 1, and the liquid reactant is injected into the kettle body 1 through the liquid inlet pipe 3, and the kettle body 1 The top of the body 1 is fixedly connected with a motor 4, and the shaft extension end of the motor 4 is fixedly connected with a driving shaft 5, and the driving shaft 5 extends into the kettle body 1, and a ring gear 6 is installed inside the kettle body 1, and the driving shaft 5 is sleeved There is a driving gear 7, a driven gear 8 is installed between the drivi...

Embodiment 2

[0024] On the basis of Embodiment 1, a liquid level regulating device is installed at the bottom of the kettle body 1, and the liquid level regulating device includes a liquid level regulating chamber 15, a lifting plate 17, a screw mandrel 19, a sleeve 20, a supporting plate 21, a rotating shaft 22, The bevel gear set 23 and the crank handle 24, the lower surface of the kettle body 1 is fixedly connected with the liquid level adjustment chamber 15, the bottom of the kettle body 1 is provided with a through hole 16, and a filter screen is installed on the through hole 16, and the kettle body 1 passes through the through hole 16 communicates with the liquid level adjustment chamber 15, the liquid reactant in the kettle body 1 can enter the liquid level adjustment chamber 15 through the through hole 16, and the filter screen is used to prevent the solid reactant debris from entering the liquid level adjustment chamber 15 through the through hole 16 , the inside of the liquid leve...

Embodiment 1、 Embodiment 2

[0026] In combination with Embodiment 1 and Embodiment 2, the working principle of the present invention is: the solid reactant is dropped into the still body 1 through the feeding port 2, the liquid reactant is injected into the still body 1 through the liquid inlet pipe 3, and the motor 4 is started to drive the The driving shaft 5 rotates, and then drives the crushing shaft 9 to rotate. The crushing shaft 9 revolves around the driving shaft 5 while rotating, which greatly improves the crushing range. The contact area of the substance can be improved, and the reaction rate can be improved. The stirring blade 11 is used to stir the liquid reactant, so that the solid reactant and the liquid reactant can be mixed more uniformly, which is helpful for the chemical reaction. The solid reactant falls on the sieve plate 14, and the The pressure roller 13 crushes the solid reactant, further increases the contact area between the solid reactant and the liquid reactant, increases the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com