Image testing method for chemical fibre thermal contraction rate and testing apparatus thereof

A technology for thermal shrinkage and image testing, applied in measuring devices, optical devices, textile testing, etc., can solve the problems of low measurement accuracy of thermal shrinkage of chemical fibers, and achieve improved reliability, accurate and reliable control, and improved weight. present effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

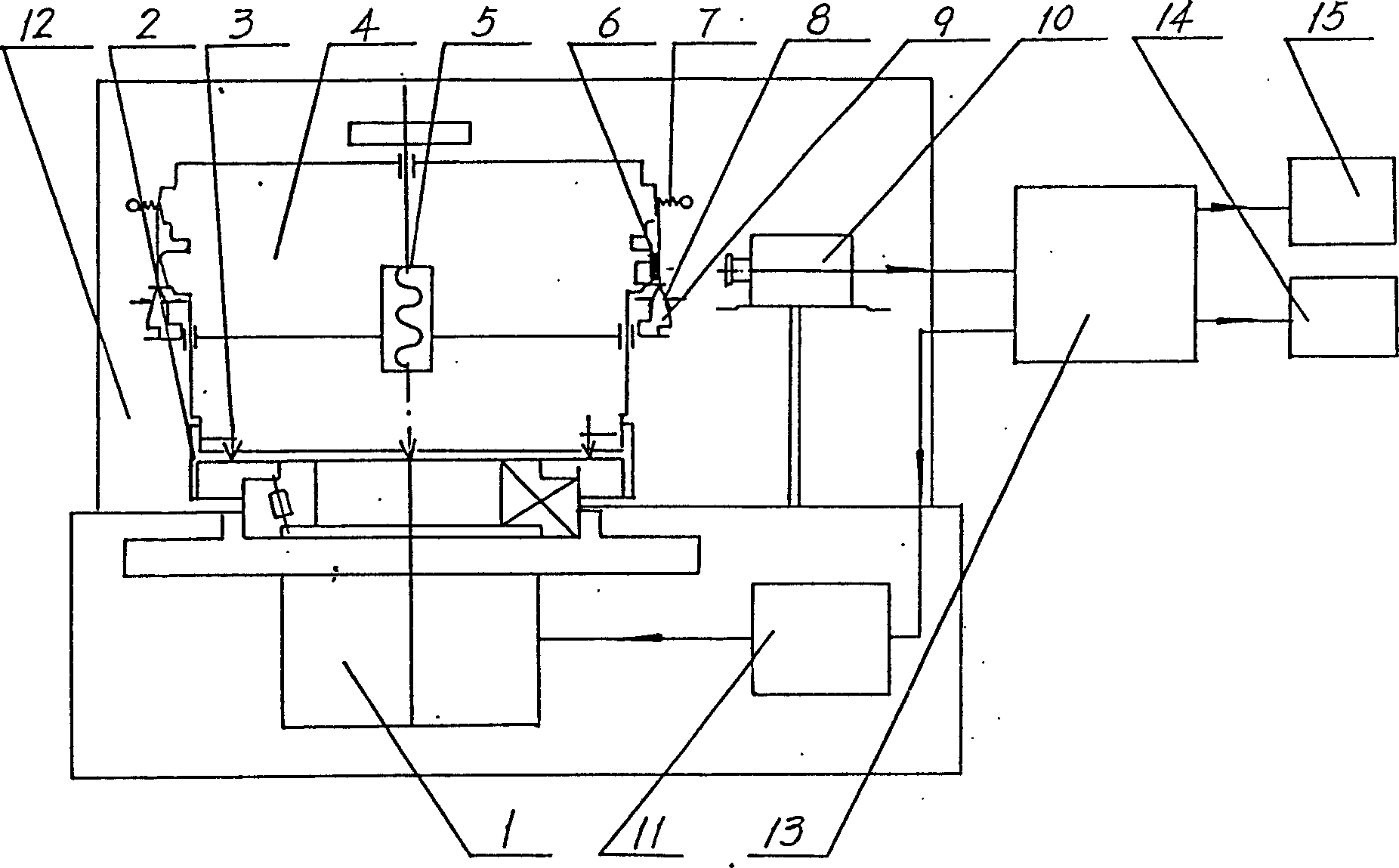

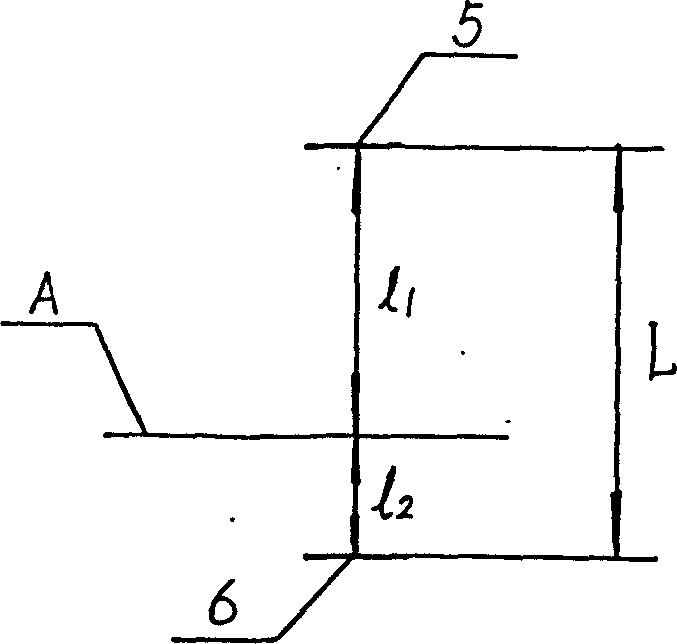

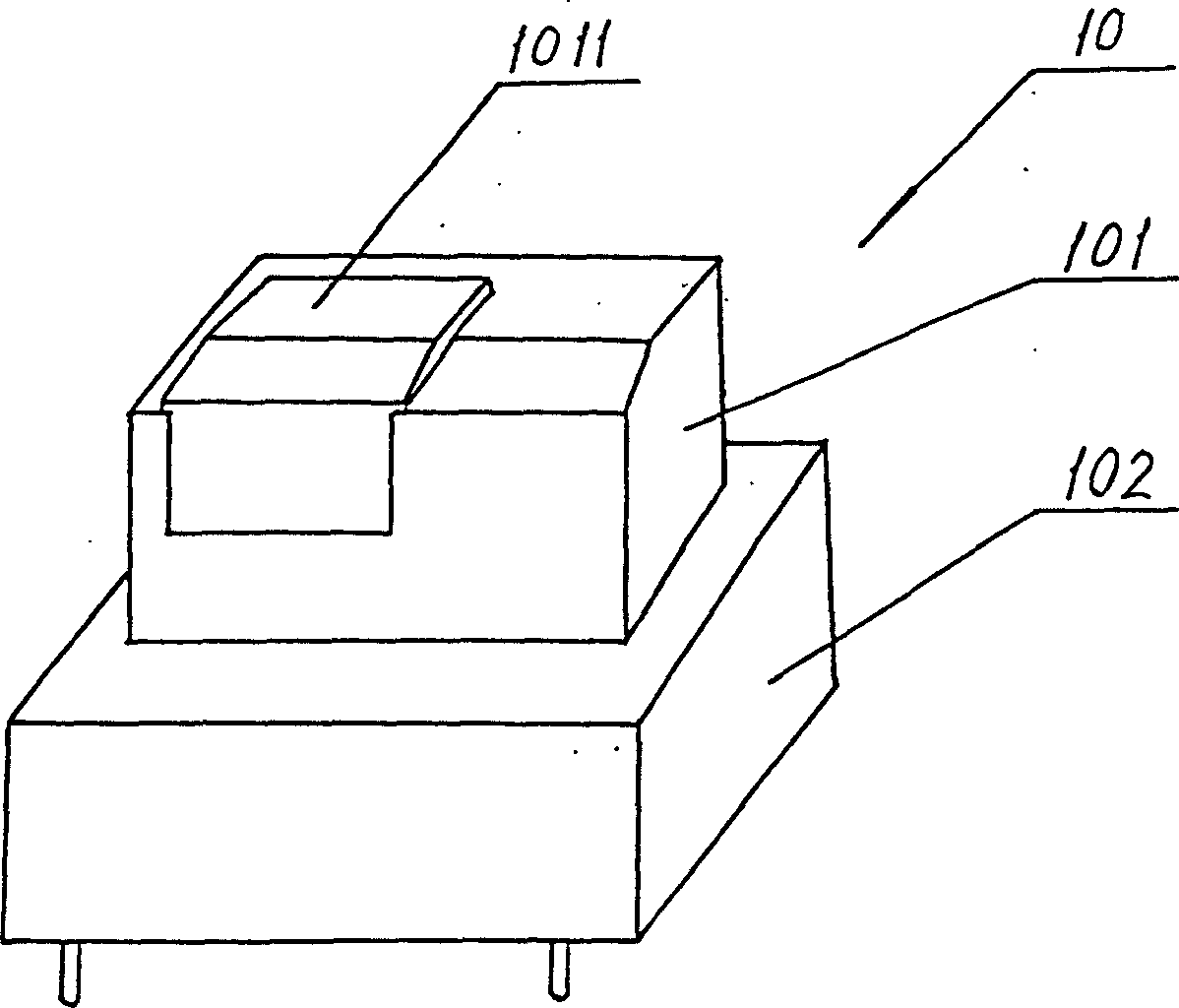

[0029] Such as figure 1As shown, the present invention provides an image testing method for measuring the thermal shrinkage rate of chemical fibers and its testing device, which can respectively measure the length of a single fiber sample before and after heating, and divide the difference between the two lengths by the single fiber The thermal shrinkage rate of the single fiber sample can be obtained from the original length of the sample before heating. A kind of test method of chemical fiber heat shrinkage rate of the present invention is characterized in that it is realized by the following steps: first open the power switch of fiber heat shrinkage rate test device and computer to preheat for half an hour, and install the The upper holder 7 is a spring clip type structure, and one end is fixed on the top of the sample garden cylinder holder 4. When the spring is opened by hand toggling its extended head end, the tension clip type lower holder 8 can be hung with tweezers. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com